-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Contactez-nous -

Carrières -

Étudiants et universitaires -

-

S'inscrire -

Déconnexion -

Espace client -

Support -

Communautés partenaires -

Contacter le service commercial

Pour les États-Unis et le Canada

+1 844.462.6797

-

ANSYS BLOG

May 26, 2022

Ansys Maxwell on Cloud Generates the Fastest and Most Accurate Electric Machine Efficiency Maps

Electric motors are used in many different devices, from cordless drills and electric vehicles to autonomous drones, cordless vacuums, electric lawnmowers, electric bikes, and more. As each device operates and controls a motor to provide specific speed and torque operating points, the goal of the motor and electronic controls is to deliver power to the mechanical shaft with optimal efficiency over the device’s entire operating range. The goal of a machine’s design and engineering team is to extend a device’s operating range and make the motor and drive system work more efficiently, which can lead to improved battery life and a reduction in the size of the device.

Electric Machine Efficiency Maps

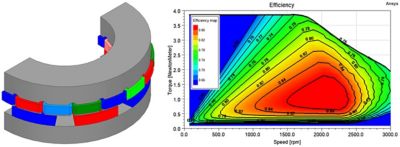

Efficiency maps are a useful tool for electric machine designers to look at the performance of a machine over the operating points of torque and speed under realistic controls. Simulation gives us the ability to design a high-performance device that meets system requirements and delivers optimal performance for its entire operating life. The combination of simulation and efficiency maps enables motor designers to create a concept of the motor geometry, estimate its performance and efficiency, and assess the boundary of the accessible operating range over torque and speed. Efficiency maps and simulation are required for all electric traction motors in electric and hybrid vehicles today, and they are increasing in use for all variable speed power devices. This data can also be used in further system modeling of the motor operation and drive cycle analysis.

Figure 1. Animation of result plots for efficiency maps

There are now two built-in Ansys solutions to create accurate and robust efficiency maps, whether you are using the Maxwell finite element analysis (FEA) electric machine toolkit or using the Ansys Motor-CAD lab tool. There are a variety of design decisions that can inform whether the electric machine model requires Motor-CAD or Maxwell, from 3D design topologies to advanced material models.

Let's focus on Maxwell’s electric machine tool kit with Ansys Cloud. There are improvements in the 2022 R1 release that elevate the fidelity and robustness of these map solutions, specifically for complicated induction machine models. There are also workflow improvements to Cloud, which enable on-demand high-performance computing (HPC) for fast turnaround times. Ansys Cloud makes previously impractical simulations accessible to any engineering team and can turn hours of simulation time into minutes. We will look at the implications and explore this workflow through this blog.

There are two parts at the core of efficiency map calculations. First is the high-fidelity Maxwell transient solver, which can include a variety of electromagnetic loss effects that contribute to the accuracy of the electronic machine performance calculation. Second is the workflow automation contained within the machine tool kit (described in detail in this prior blog post). To achieve the higher accuracy required from the FEA simulation, computation time and resources could increase due to the model’s complexity. This could make some simulations take longer to produce the efficiency map at the desired accuracy. For example, a 3D simulation (such as the axial flux model below) requires more simulation resources than a standard 2D electric machine model. The capabilities described below enable us to efficiently produce an effective and accurate efficiency map for these large 3D motor models.

Figure 2: The efficiency map tools enable a motor geometry finite element analysis (FEA) simulation model to construct a performance map of speed and torque operating points.

The built-in process for the workflow involves using the built-in Application Customization Toolkit (ACT) wizard within Maxwell. By using the tool kit wizard, we can enter several pieces of information about the motor and drive parameters, such as the drive voltage, maximum current capabilities, and maximum speed for motor operation. Once the information is entered, there are several available options for solving locally, either on a separate workstation, in a computer cluster, or on the cloud. Once the option is selected, the tool kit automates the process of validating the design settings, winding orientation, and rotation direction. It also creates the simulation model for solving the motor performance characteristics needed for efficiency maps.

Figure 3: Toolkit usage

There have been continuous improvements to each type of electric machine available in the tool kit that enhance the robustness, capabilities, and computational speed of extracting efficiency maps from this workflow. The most notable improvements in the 2022 R1 release are focused on the induction machine type, where the robustness of the map generation provides the most accurate and smoothest maps to date. Speed improvements over the last several versions allow synchronous machines (permanent magnet, wound-field, and synchronous reluctance types) to be solved in a fraction of the time. Additionally, flexibility in defining AC winding resistance calculations and loss scaling factors provide key usability improvements.

With all this power to automate a large simulation space, we need additional computer resources to make high-accuracy models practical. To do this, engineers can turn to Ansys Cloud to leverage hardware and software tools on demand. By using the built-in Cloud submission tools, we can solve every design point in parallel and return the result in a fraction of the time. This example 3D axial flux model generated from our Ansys RMxprt software takes 1 hour from start to finish, including the 30-minute Cloud solution time, using a small Cloud configuration. On a single laptop, a high-fidelity map solution could take a day using the same settings. Because the machine toolkit and Cloud job submission are both built into the Ansys Electronics Desktop (AEDT) interface, the workflow is located within a single window and can be further automated to suit your needs.

Figure 4: Cloud connection within the Ansys Electronic Desktop (AEDT) interface

This comprehensive motor solution enables motor designers to look at multiple fidelities of motor simulation, including the most demanding ones. The combination of built-in Ansys simulation workflows and cloud computing enables access to simulation capabilities for any design engineer.

Contact us to ask about Ansys Cloud and to see how the Maxwell electric machine toolkit can enable efficient machine design.