-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Contactez-nous -

Carrières -

Étudiants et universitaires -

-

S'inscrire -

Déconnexion -

Espace client -

Support -

Communautés partenaires -

Contacter le service commercial

Pour les États-Unis et le Canada

+1 844.462.6797

-

ANSYS BLOG

June 15, 2022

4 Ways to Increase Safety and Security of Battery Management Systems Using Simulation

The world is going electric. Cars, aircraft, industrial processes, energy storage, you name it: Industry is making a major shift toward electrification, and with that comes an ever-growing demand for more batteries. But transitioning to a lower-carbon future doesn’t mean people or companies are ready to compromise on efficiency; they expect at least similar — or superior — performance from electric batteries. Delivering this can prove to be quite complex. In vehicles, for instance, batteries have to be powerful enough to control an electric motor, cabin climate, several infotainment systems, and more.

To achieve this, batteries need to charge efficiently, store energy effectively, and operate safely, delivering reliable performance over years of usage. But smart batteries are complex systems that require an embedded control unit: the battery management system (BMS).

The BMS is the brain of electric power systems. It continuously monitors conditions, redistributes energy resources, and sends alerts in the event of a problem. This whole system must operate optimally to ensure safe and efficient energy usage.

The BMS includes embedded software for real-time monitoring and control of rechargeable batteries to provide reliable power, even in complex applications. They control many elements such as voltage, current, and temperature to balance the charge between cells, protect from overvoltage, and ensure a safe operation despite repetitive charging and discharging cycles.

Today, many of the engineering challenges surrounding the electrical revolution center on the electric battery and its management system. Let’s take a look at four ways you can use simulation to design a BMS that meets the major challenges of efficiency, safety, and reliability.

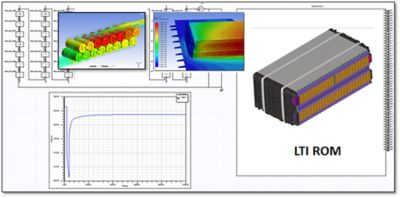

1. Optimize Battery Design with Multiphysics Simulation

Battery engineers and designers are constantly exploring materials that will be more energy efficient and less prone to overheating and burning. Controlling the temperature of batteries is essential to prevent them from becoming too hot and, catastrophically, catching on fire. Despite each material having unique properties, Ansys multiphysics solutions enable you to thoroughly model a battery system. Multiphysics coupling gives engineers a complete picture of the structural, thermal, and electrochemical response of a battery.

- Ansys Fluent is used for cell design, thermal management, and thermal runaway, helping engineers design batteries that will be resistant to thermal abuse.

- Ansys Mechanical is used for modeling structural stresses and strains produced by differential heating and cooling. It tracks the effects of temperature on the structure to ensure that the battery’s components can withstand any thermal-induced stresses. It also simulates structural failure in these conditions and determines whether a new design will prevent failure.

High-fidelity thermal and structural analysis for a battery module using Ansys multiphysics solvers.

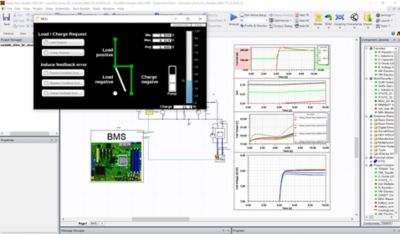

2. Perform System-Level Modeling Using Digital Twins

Following multiphysics coupling, when all the components of a battery system are ready to be connected, you can gain an accurate perspective on how the BMS and battery will perform throughout their entire life cycle using a digital twin. Ansys Twin Builder accounts for all physical changes during a battery’s design, manufacturing, and operating life cycle. It simulates how they will work together to achieve optimal efficiency.

However, optimally designed components do not necessarily result in optimal systems. When these components are powered, sensed, and controlled together as an integrated system, they might perform differently than when they were tested as standalone components. Twin Builder can perform closed-loop testing that encompasses the entire connected system to detect any component weaknesses and correct them to produce a battery system that operates at maximum efficiency.

System simulation integrating thermal and electric models and BMS software-in-the-loop.

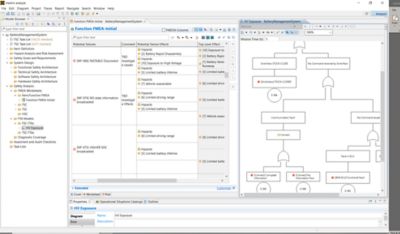

3. Ensure the Safety of BMS Design with System Architecture

Ensuring the functional safety of BMS is of the utmost importance, but it is not an easy task. To perform key functional safety analyses across many industries, especially the automotive sector, one integrated tool enables you to perform efficient and consistent execution of safety-related activities.

Ansys medini analyze performs key safety analysis procedures as specified by different standards in different industries, along with diagnostic and failure mode and effects (FMEA) analysis. For automotive systems, it checks that the BMS software satisfies the functional safety standard ISO 26262, starting with the identification and description of functions and malfunctions of the BMS.

Once malfunctions have been identified, a hazard and risk analysis is performed to identify the hazardous events and their impact on safety by determining the automotive safety integrity level and corresponding safety goals and safety requirements.

Safety analysis connected to system architecture model using several key analysis methods.

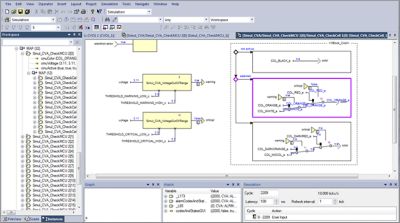

4. Automatically Generate Embedded Code for Battery Management Software Reliability

Because battery systems combine hardware and software, development teams have traditionally worked separately. Today, Ansys is changing that paradigm with an integrated simulation platform for battery design and BMS development.

The embedded software in the BMS can be generated and verified automatically using Ansys SCADE Suite. The SCADE product line provides a model-based development environment for critical embedded software at application level, deployed in electronic control units of different automotive systems with optimized code quality and development costs. Using a software controller, engineers can intelligently monitor a battery’s operating conditions and oversee its safe operations. Utilizing Ansys SCADE’s end-to-end model-based development solution eliminates the need for costly code reviews and low-level testing.

Many experts from different engineering areas can easily understand the model-based software and review the model’s functionality. The solution is compliant to architecture standards such as AUTOSAR and ASPICE, and the automatically generated code is compliant to safety certification standard ISO 26262.

“With SCADE, many things have become faster. The improvements in our largest unit, which is responsible for diagnosing the battery management system, have been dramatic. Overall we have become significantly faster in terms of testing, not only in terms of pure testing, but also for coverage analyses due to the elimination of code analyses,” says Dr. Daniel Kirschner, head of Tools & Methods/Battery Management System at Volkswagen.

Embedded software simulation using a control panel to quickly test and debug the model.

Simulate the Battery Development Process

Simulation helps engineers design BMS throughout the development process. The combination of Ansys’ simulation capabilities mentioned above is essential for rapid virtual prototyping of a BMS, as more and more systems will rely on battery power in the future. The main benefits of model-based development are the ability to have reference models, reuse them across different development phases, and reduce the effort and risks of the transitions between design phases. Ansys solutions for embedded software and functional analysis enable BMS development for secure, safe, and efficient battery operation.

To learn more about BMS design and how multiphysics systems simulations can optimize batteries, watch the webinar Safer Electric Vehicles with Battery Management Systems.