-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Ansys s'engage à préparer les étudiants d'aujourd'hui à la réussite, en leur fournissant gratuitement un logiciel de simulation.

-

Contactez-nous -

Carrières -

Étudiants et universitaires -

-

S'inscrire -

Déconnexion -

Espace client -

Support -

Communautés partenaires -

Contacter le service commercial

Pour les États-Unis et le Canada

+1 844.462.6797

-

ANSYS ADVANTAGE MAGAZINE

January 2021

Collaborate on Seamless Optics Design for ADAS

By Sanjay Gangadhara, Chief Technology Officer Zemax, and Ludovic Manillier, Business Developer Ansys OPTIS

Simulation via Ansys Speos replicates how an ADAS camera “sees” a vehicle’s physical surroundings in daylight, nighttime and foggy conditions.

Winning in today’s crowded automotive landscape means being first to market with increasingly autonomous vehicle designs. One obstacle?

A disconnected workflow that increases the time and cost of developing the advanced optics underlying ADAS perception systems. A new technology partnership between Ansys and Zemax is making the optics development process exponentially faster, helping customers reach the finish line first.

A recent report from the U.S. National Highway Traffic Safety Administration revealed that errors made by human drivers cause 94% of the 40,000 car accidents that occur in the U.S. annually. Advanced driver assistance systems (ADAS) ― including forward collision warning, automatic braking, lane keeping and pedestrian detection systems ― are critical to minimizing the tens of thousands of crashes caused by driver distraction or inattention each year.

Perception Performance Challenges

As automakers and original equipment manufacturers (OEMs) race to develop new ADAS technologies that increase the level of automotive autonomy and minimize the element of driver error, perception systems are a mission-critical component. The concept of driver assistance relies on the ability of the vehicle’s sensors to accurately detect hazards like pedestrians and trigger an appropriate response from braking, steering and other systems.

The essential role played by perception technologies means that today’s automotive development teams must work quickly and cost-effectively to launch innovative new ADAS sensors, including advanced optics that work under a range of weather conditions, lighting levels, ambient temperatures and other operating parameters.

Each ADAS optics component must be optimized for a specific use case, which considers its position on a vehicle and its primary function. For example, an optical component might support a back-up camera used in parking lots, or a front-mounted camera that triggers the emergency braking system when a pedestrian is detected on the road ahead. Optics may or may not need to have strong peripheral vision. They almost universally need to function well under a range of weather and lighting conditions.

These performance characteristics influence a range of design choices, from lens shape and profile to choice of materials. All these factors combine to make the task of ADAS optics design extremely complex. Equally complex is the job of verifying that these optics will perform reliably when mounted on a vehicle and exposed to real-world driving conditions.

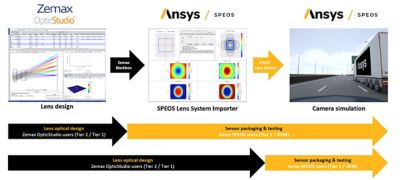

Two engineering solutions have been proven to meet these challenges, leading to the rapid development of ADAS optics. Zemax’s OpticStudio and Ansys Speos are often used in combination to first design the lens, then simulate its performance in a static or dynamic driving situation. These tasks are managed by two different teams ― an optical engineering team and a virtual testing team ― which necessitates hand-offs and collaboration.

The outdated, functionally siloed workflows that support the optics development process represent one of the biggest obstacles faced by these teams. Historically, optical engineers have developed a lens model inside Zemax’s industry-leading optical design software, OpticStudio, then moved the model manually to Ansys Speos for camera simulation and performance verification by the virtual testing team. Because data was exported manually and mathematically complex calculations ― including raytracing ― needed to be remodeled in Speos, this process was slow and error-prone. Following the initial simulation, any design iterations followed this same tedious and time-consuming process.

The result? Slow launch schedules and significant budget overruns. Worse, many development teams had concerns about data security and intellectual property (IP) protection as designs were repeatedly handed off among different development functions and disparate technology tools.

By partnering to import the Ansys Speos lens system simulator directly into Zemax’s OpticStudio, the two companies have eliminated the functional and technological obstacles to seamless ADAS camera design.

Zemax and Ansys: A Clear Solution

Recognizing that this manual process represents an obstacle to rapid ADAS innovation, Ansys and Zemax have collaborated to link their industry-leading solutions via a secure technology interface.

The Ansys Speos lens system importer, created in a partnership between Ansys and Zemax, is designed to streamline workflows and protect IP. This new end-to-end solution for camera testing and validation leverages the component-level design, modeling and simulation capabilities of Zemax’s OpticStudio with the modeling, simulation, analysis and visualization benefits of Ansys Speos. As a result, engineers developing advanced optics for ADAS camera designs can quickly and accurately test, validate and iterate their designs.

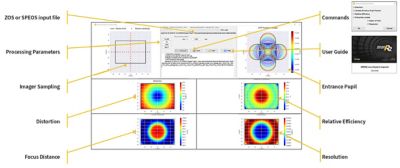

The Speos lens system importer is built on top of the highly functional and flexible OpticStudio Application Programming Interface (ZOS-API), allowing it to be used to bring any camera lens design from Zemax’s OpticStudio, into Ansys Speos simulation software. The entire optics model can be transferred using the secure “black box” technology in OpticStudio, so IP is protected without limiting the simulation analysis. All data is securely and automatically pulled into the simulation tool, without any need to recreate key calculations. The simulation can begin immediately ― leading to an end-to-end development process that is exponentially faster than the historical, manually intensive workflow.

The new streamlined workflow is already benefiting Ansys–Zemax customers, including Continental. “Ansys offers the automated execution of simulation plans to solve complex problems in the design of autonomous vehicles,” said Konrad Rothenhäusler, design for Six Sigma Coach, ADAS business unit at Continental. “The end-to-end optical testing solution from Ansys and Zemax enables us to exchange optical transfer functions ― which determines the quality of the projected image ― while protecting our sensitive design data. This workflow will empower our team to explore new camera designs faster, cheaper and with less risk.”

An easy-to-use interface in the Ansys Speos lens system importer makes it simple to control the simulation parameters and verify accurate lens performance under a variety of lighting and atmospheric conditions.

A View Toward Improved Productivity

So how exactly does the accelerated and streamlined process work? First, optical engineers design a complete optics system in Zemax OpticStudio, performing comprehensive design optimization and tolerancing. The resulting virtual model considers every factor that might impact the quality of ADAS perception systems, including lens geometry, lens position, materials composition and the effects of stray light.

The Speos lens system importer generates a model of the complex Zemax camera design, then brings it directly into Ansys Speos for simulation and physical verification. While it includes key calculations and dimensions, the model protects any sensitive IP that went into the development of the lens, providing a higher level of security for optics engineers.

Whether the sensor’s output is projected on a screen or displayed in a virtual reality environment, Ansys Speos provides ADAS engineers with a visual simulation of their optical system as installed on a car. Ansys Speos supports both static and dynamic simulations, on a highway or in a parking lot. It can consider a range of ambient lighting conditions, such as nighttime, as well as the full range of operating temperatures that might affect a car. Ansys Speos can also simulate atmospheric conditions including fog, which has proven especially problematic for the designers of ADAS perception systems. To fully replicate real-world operating environments, Speos can combine a variety of conditions ― for example, nighttime/hot/foggy or daytime/cold/clear.

Based on the Ansys Speos simulation, optical engineers can then improve the perception quality of their cameras and lenses in Zemax OpticStudio by re-optimizing their designs. OpticStudio supports comprehensive and easy-to-use tools to target properties such as image brightness and image sharpness as a part of the optimization process, and it also provides robust simulation of camera performance over the large fields of view typically required by ADAS perception systems. The new lens model can easily be imported into Ansys Speos for additional simulation and verification. By significantly speeding up the iterative design process, the new Ansys–Zemax technology integration helps ADAS development teams get fully validated opto-mechanical designs out to market faster.

The Ansys Speos lens simulator has the power to simulate multiple camera lenses mounted on ADAS-equipped vehicles under dynamic driving conditions.

Envisioning an Autonomous Future

While the immediate goal of ADAS technology is to minimize the number of crashes caused by driver error, certainly the long-term goal is to support fully autonomous driving. By improving and accelerating the design process for sensor optics ― and leveraging simulation to reduce physical testing and prototypes ― the Ansys–Zemax technology partnership is helping automotive customers like Continental to seize leadership in the race to commercialize a fully autonomous, or Level 5, vehicle.

By reducing the time and cost of product development, while fostering ADAS optics innovations, Ansys and Zemax have joined forces to address a critical customer need. As automakers and OEMs acquire and apply an increasing number of advanced engineering tools, it is incumbent on technology providers to ensure that these solutions are optimized for tight integration ― and the rapid results that lead to success in a fast-moving, highly competitive industry.

Commençons

Si vous êtes confronté à des défis d'ingénierie, notre équipe est là pour vous aider. Forts de notre expérience et de notre engagement en faveur de l'innovation, nous vous invitons à nous contacter. Collaborons pour transformer vos obstacles techniques en opportunités de croissance et de réussite. Contactez-nous dès aujourd'hui pour entamer la conversation.