-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

Ansys Materials and Chemical Processing Solutions

Accelerating Digital Transformation in the Processing Industry

Ansys simulation solutions deliver operational cost reductions for enhanced competitiveness today—and the innovation behind the advanced materials systems of tomorrow.

Accelerated Innovation and Cost Reduction with Simulation

Ansys simulation solutions enable materials and chemical process companies to dramatically improve overall equipment effectiveness (OEE), capacity and raw material utilization, resulting in more efficient operations and reduced costs.

From equipment and processes to chemical and petrochemical refining to glass, polymer and metals manufacturing, Ansys simulation solutions accelerate innovation for tomorrow’s advanced materials systems while helping our customers conserve energy, minimize environmental impacts, meet higher regulatory standards and streamline product development.

-

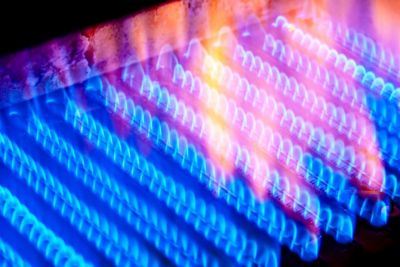

Materials Processing

-

Environment and Water Treatment

-

Chemicals Processing

Optimize the most difficult materials processing challenges

Engineering simulation enables optimization of even the most complex and resource-intensive processes, minimizing their environmental footprint while managing materials intelligence across the enterprise.

Improve pollution control and water treatment

Simulation can improve the performance of pollution control systems, enhance the quality of air and potable water and reduce the environmental impact of wastewater discharges.

Increase innovation in chemical processing without sacrificing safety

Simulation enables chemical processes innovation and optimization while ensuring safe operations, reduced energy usage and improved emissions control.

Applications

Simulation is driving innovation across the materials and chemical process industry. Ansys’ solutions span from detailed physics-based analysis of chemical process to system level simulations.

By optimizing product and process performance, simulation makes a quantifiable business impact by improving yields while eliminating waste.

Video Title

Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries

The Business Case for Material Intelligence

Materials information management software has lagged behind other areas of digital transformation.

Materials Information is Critical To Productivity, Innovation, Cost and Risk In Engineering Enterprise.

The fourth industrial revolution is underway, thanks to simulation and materials data management. Enterprise wide materials intelligence is the next frontier in the transformation to a digital processing industry.

Most areas of manufacturing have undergone dramatic change in the digital transformation that is driving the fourth industrial revolution. Computer-aided approaches are now standard in most areas of product engineering. Materials information has not yet experienced the same integration into the digital transformation landscape despite its crucial role – often on the order of millions of dollars – in the design and manufacture of products.

Ansys makes the case for why materials information management should be regarded as a core engineering technology and how it can benefit manufacturers. Increased materials intelligence can help address key challenges at every step of the design process, from reducing product weight to improving product lifetimes and reducing warranty claims. A systematic approach to materials information can help manufacturing businesses in every sector.

Video Title

Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries

Let’s Get Started

If you're facing engineering challenges, our team is here to assist. With a wealth of experience and a commitment to innovation, we invite you to reach out to us. Let's collaborate to turn your engineering obstacles into opportunities for growth and success. Contact us today to start the conversation.