-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

Modeling & Simulation of Heat Exchangers

Optimize heat exchanger design for performance and energy efficiency, material selection, durability and life prediction under harsh conditions.

Cost-Effective Performance and Durability

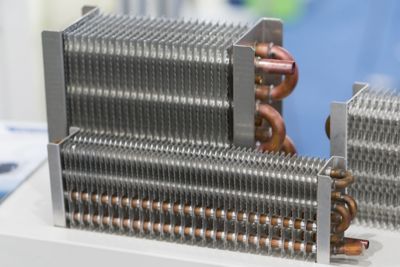

Used in a variety of settings across a range of scales, heat exchangers must perform reliably, often in harsh conditions, and be durable enough to operate effectively despite extremes of cyclical thermal loading—sometimes for years without replacement. Simulation offers a critical tool to optimize heat exchange performance, select the most appropriate materials and predict durability and life. Ansys heat exchanger simulation application capabilities provide that reliability.

-

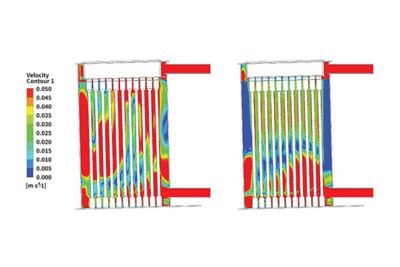

Diffuser and Tube Thread Shape Optimization

-

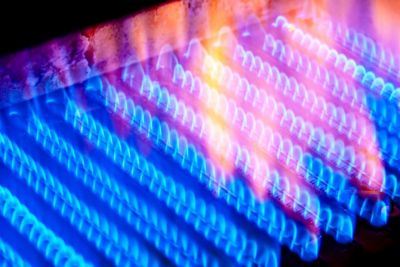

Condensation and Evaporation

-

Conjugate Heat Transfer

-

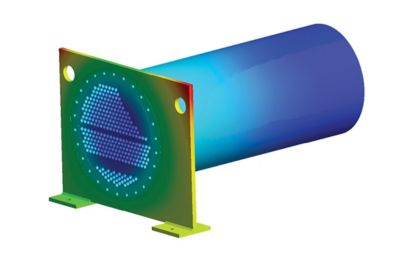

Integration with the Overall System Model

-

Hot and Cold Cycle Fatigue

Shape Optimization

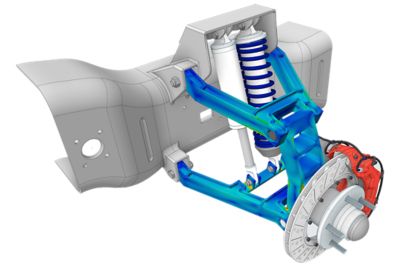

Heat exchanger shape selection can be optimized by leveraging parameters, adjoint methods and response surfaces.

Conjugate Heat Transfer

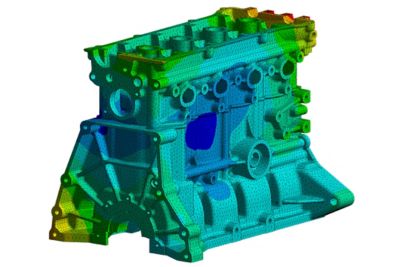

Performing steady or transient conjugate heat transfer simulations determines heat exchanger performance and the impact of thermal stresses. Models can include fluid structure interaction, fatigue life prediction and multiphase boiling, condensation and evaporation.

System Level Integration

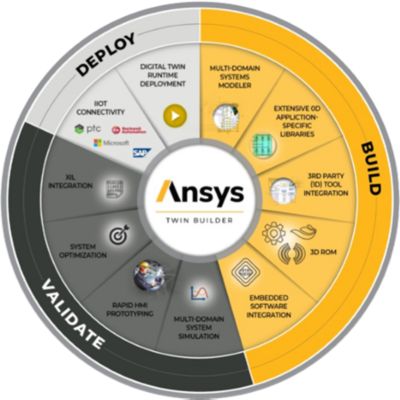

Using reduced order models (ROMs), high-fidelity physics simulations integrate with overall system level models for process integration and design optimization (PIDO).

Featured Products

“Using Ansys for pressure vessel and exchanger analysis provides the robustness and reliability needed to solve the large, complex models.”

— Richard Grant, President Grantec Engineering Consultants

Featured Resources

BLOGS

Let’s Get Started

If you're facing engineering challenges, our team is here to assist. With a wealth of experience and a commitment to innovation, we invite you to reach out to us. Let's collaborate to turn your engineering obstacles into opportunities for growth and success. Contact us today to start the conversation.