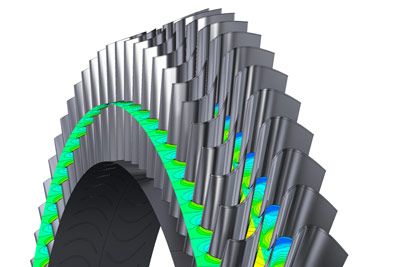

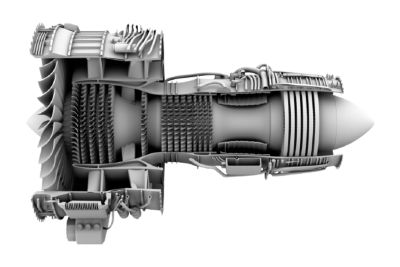

15% Reduction In Fuel Burn

Leverage simulations to tune the overall performance of your gas turbine by reducing specific fuel consumption.

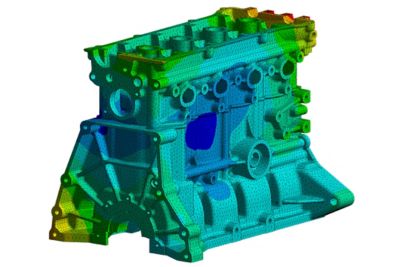

30% Cost Reduction

Explore how efficient simulation solutions help to cut development costs and reliance on physical testing.

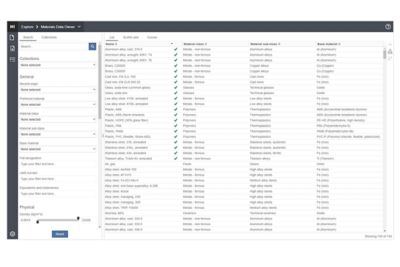

33% Design Cycle Time Reduction

Discover how simulation helps to streamline the design process and reduce cycle time and minimize overdesign.

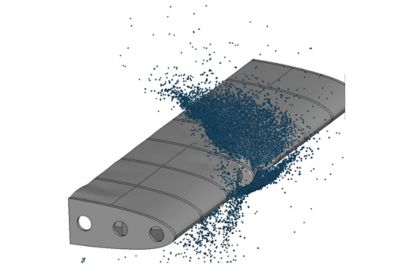

9x-16x return on investment

Investing in simulation provides a competitive edge.