-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

ANSYS BLOG

Aptil 14, 2021

Realize the Sustainable Promise of Hydrogen Combustion

Hydrogen is poised to decarbonize many sectors of our economy. It can be directly used in fuel cells for carbon-free power, or in gas turbines where its high energy density, higher auto-ignition temperatures and ability to lean-burn are favored. Finally, the Paris Climate Agreement and aviation community’s commitment to drastically lower emissions by 2050 are also driving hydrogen combustion research and development.

Despite its potential as a “golden” fuel or energy carrier, burning hydrogen in engines poses several challenges, including flashback, acoustic instabilities, autoignition and flame holding inside the burner. Engineers can address these challenges with simulation.

Simulation Saves Time and Costs

Rig testing does provide valuable information to help combat these challenges, but is expensive and time consuming, and with 100% hydrogen, it can mean sacrificing the critical components and instrumentation of the rig. Numerical simulations can provide deeper characterization of many complex phenomena inside gas turbine combustion chambers. For example: The video in figure 1 represents a complex aerothermal field inside an aero-engine combustor predicted by computational fluid dynamics (CFD) analysis using Ansys Fluent.

Figure 1: Aerothermal field inside an aero-engine combustor

Accurate prediction of such complex phenomena and emissions inside gas turbine engines requires high fidelity and validated scale resolving turbulence models, combustion models and fast transient numerics schemes. In the above example, a stress-blended eddy simulation (SBES) turbulence model was used in combination with Mosaic meshing technology from Ansys to resolve highly unsteady flow structures. Discrete phase modeling in a Eulerian-Lagrangian framework was used to model fuel spray while accounting for secondary breakup. Combustion was modeled with the flamelet generated manifold (FGM) model, which represents thermo-chemistry by mixture fraction and reaction progress. This modeling strategy (SBES-FGM) has been validated for accurate prediction of flame behavior and emissions for jet engines as well land-based gas turbine combustors.

Applying Simulation to Hydrogen Combustion

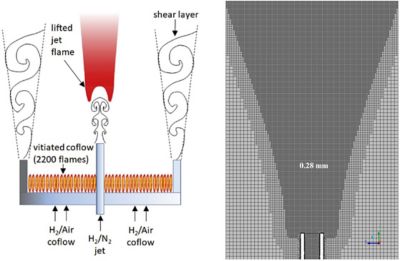

The above-mentioned modeling techniques with optional extensions have also been proven to work for hydrogen-blend or pure-hydrogen fuels. Such extensions include modified definitions of reaction progress variables, and in some cases accounting for differential diffusion (different mass and thermal diffusivities for different species). A successful application of such a modeling framework for hydrogen combustion is presented in figure 2 on a Cabra case1, which is a representative configuration of flame holding in a generic gas turbine premixing system.

Figure 2: Cabra’s case (left). Ansys poly-hexcore mesh in the zone of interest (right).

The hydrogen fuel jet in the Cabra case above is surrounded by a coaxial coflow of combustion products of 2,200 lean premixed hydrogen/air flames. Large eddy simulations (LES) were performed with the pressure-based solver in Fluent and the subgrid scales were modeled with the dynamic Smagorinky Lilly formulation. Combustion is modeled using FGM with a finite rate closure for the progress variable source term and an algebraic formulation for the progress variable (PV) and mixture fraction (Z) variances. The video in figure 3 shows the predicted hydrogen flame structure in terms of temperature and mixture fraction distribution over a selected time period.

Figure 3: Hydrogen flame (thermal field on left and mixture fraction on right) details captured by large eddy simulations.

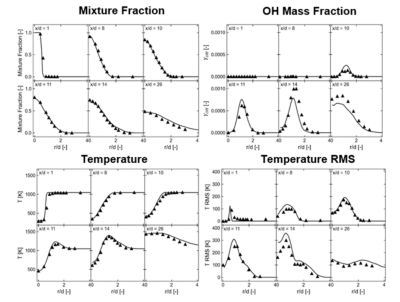

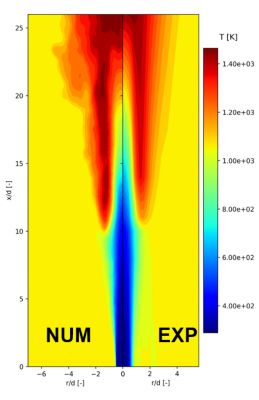

The video in figure 3 shows that Mosaic-enabled poly-hexcore meshes provide good spatial resolution to capture the formation of instabilities in the shear layer. The radial plots of various variables and contour plot of the thermal field, which are shown in the figures 4 and 5, compare numerical predictions with experimental measurements.

It is clear that LES-FGM simulation predicts the distribution of mixture fraction, temperature and species in very close agreement with experimental data. Simulations also accurately reproduce the flame front thickness. Prediction of flame at the leading edge is crucial for whole-flame prediction affecting the mixing downstream. The use of a diffusive flamelet approach allows more accurate reproduction of the flame anchoring, resulting in close agreement with the experimental data.

Figure 4: Mass weighted averaged radial profiles of mixture fraction, species and temperature for different axial positions. (Lines represent numerical simulation results; dots represent experimental results.)

Figure 5. Predicted mean temperature distribution for Cabra hydrogen flame and its comparison with the experimental data.

Simulation Supports Hydrogen Decarbonization Efforts

Hydrogen-powered gas turbine engines are expected to lead decarbonization efforts in the energy sector and sustainable aviation. The most complex technical challenges in using hydrogen in gas turbines can be characterized and addressed with high-fidelity simulations. The proven methodologies for simulating combustion in traditional engines have been extended and shown to also accurately predict complexities inherent in hydrogen combustion. Applying these simulation methodologies to hydrogen combustion can help the energy and aviation sectors bring more sustainable, low-carbon products to market faster while saving costs.

1. R. Cabra, T. Myhrvold, J.Y. Chen, R.W. Dibble, A.N. Karpetis, R.S. Barlow, Proc. Combust. Inst. 29 (2002) 1881–1888