Battery Management Systems Design and Validation

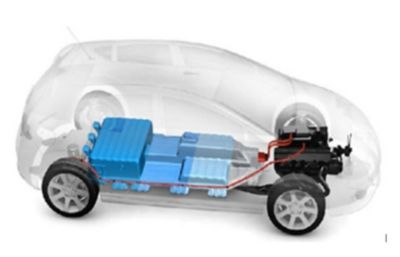

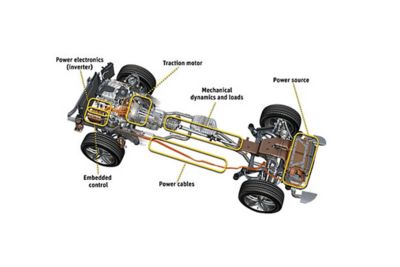

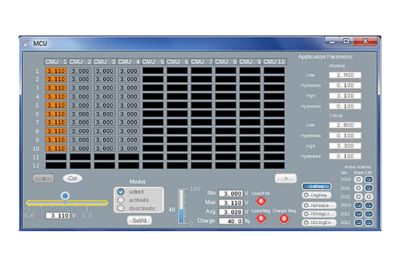

The BMS continuously monitors conditions, redistributes energy resources and sends alerts in the event of a problem.

System Architecture Selection, Functional Safety Analyses and Cybersecurity

Perform key functional safety analyses across many industries, including the automotive sector.

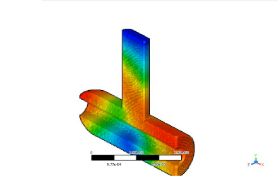

System-Level Simulation

Gain an accurate perspective on how the BMS and battery will perform throughout their entire life cycle.

Embedded Software Development and Validation

Utilizing the software controller, intelligently monitor the battery’s operating conditions and oversee its safe operations.