-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

ANSYS BLOG

March 1, 2024

What is E-mobility & How Do Engineers Design Electronic Cars?

What is E-mobility?

E-mobility, or electromobility, refers to the use of electrified vehicles for transportation purposes. It could be a car, bus, truck, or any other vehicle that is fully or partly electric, like a hybrid.

“E-mobility has become a trend that is on the rise,” says Sandeep Sovani, director of industry marketing at Ansys. “In major cities, you can spot an electric or hybrid every ride. The trend is fueled by many factors including clean energy, petrol costs and climate change fears.”

Electric vehicle incentives are proof of the emobility trend.

People, governments, automotive companies and the general community are jumping on board—as evidenced by growing incentives like specialized parking spots, tax breaks and vehicle options.

But what are the engineering challenges preventing electric cars from overtaking transportation systems?

What are the Biggest Barriers to E-mobility?

The biggest challenges to e-mobility are energy storage, charging and cost.

“If we look at a car today, we expect it to have two important features that are often taken for granted. One, that it will drive about 400 miles before refueling. And two, that we can charge it at any gas station in about 5 minutes,” says Sovani.

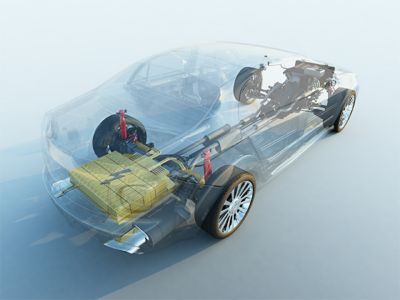

Energy storage and battery charging are some of the

biggest emoblity challenges.

Currently, electric vehicle battery technology can’t accommodate these expectations, especially in cold climates that affect performance.

Additionally, most electric cars are luxury items. Considering the costs and travel limitations, it’s no wonder why they haven’t dominated the market.

However, not all is lost. Engineers need to find solutions to these challenges for electric cars to become dominant.

“The majority of consumers don’t care what fuel goes into a car,” predicts Sovani. “You give it the fuel it needs to meet the range and recharging expectations. Once engineers develop electric solutions to meet these expectations, gasoline and diesel will be phased out.”

Will E-Mobility Gain Popularity?

The electric car has gained the public interest a few times throughout history. However, it has yet to dominate the market despite a modern concept being introduced in the 90s and Tesla’s announcement of its electric sportscar in 2006. Currently, they are a niche option, popular enough that major publications, like U.S. News & World Report, see fit to rank the top models available.

The Volkswagen I.D. R Electric car is breaking speed

records around the world.

However, electric cars have entered into the racing world in a big way. The Volkswagen ID. R Electric car has recently broken records at Pikes Peak and Nürburgring Nordschleife. Sovani points out that on these tracks the battery-powered vehicle had a few benefits when compared to traditional internal combustion engines.

First, its electric powertrain doesn’t need oxygen to operate. So, it can maintain top efficiency in the high altitude of Pikes Peak. Second, the battery only needed to run for the 8-minutes to complete the course. So, engineers could use a lighter battery by pushing it to its thermal and energy capacity limits.

“Pikes Peak was a big victory for e-mobility. The previous record was broken by nearly a minute, which is an incredible feat given that teams usually struggle to improve these records by a few seconds. It is fascinating,” says Sovani. “This raises the profile of electric vehicles in the public eye. There is no one reason people buy electric, but I think this will be one of the things they think about when they do.”

Marco Oswald, technical account manager for Continental at Ansys says, “motorsports are an extreme example of an electric powertrain. Original equipment manufacturers (OEMs) and Tier 1 suppliers are working on mass market technology to bridge internal combustion engines and electric cars. Systems simulations can help to optimize these vehicles for cost, power and efficiency.”

How to Design an Electric Powertrain

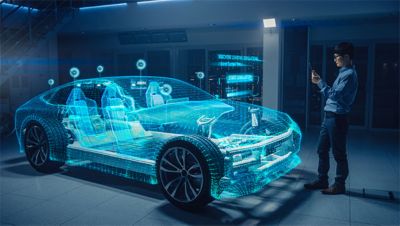

Systems simulations are some of the most important tools to designing optimal electric powertrains.

“Recently, we saw a shift from automotive engineers optimizing components to optimizing systems and system integrations,” says Oswald. “Users realize that they have to consider each component as a part of a system and all the multiphysics that entails.”

Systems simulations are crucial to designing optimal electric powertrains.

For instance, by modeling their race car’s system, and how it reacts to the track, Volkswagen Motorsports was able to optimize its electric car for Pikes Peak without overengineering the weight of the battery.

However, the design criteria of electric vehicles on racetracks are not the same as those on public roads. For instance, consumer grade batteries will need to last 10- to 15-years, travel hundreds of miles per charge and hundreds of thousands of miles per lifecycle. A far cry from the 8 minutes at Pikes Peak.

Even though the goals have changed, systems simulation can still be applied to the design of commercial cars. Instead of optimizing the systems to an 8-minute racetrack, engineers can optimize the car to the duty cycle it will experience over its lifespan.

To gain insights into the duty cycle of a car, engineers will need to turn to digital twins. Wolfram Schloter, enterprise account manager for Continental at Ansys, elaborates: “Systems simulation is one step away from twin building. Here you can make observations on how a system will behave and compare it to how it is used in the real world.”

Through the digital twin, engineers can gather information on a car’s performance and loads. From there, they can plug that data into systems simulations to gain insights into everything from maintenance cycles to further design improvements.

The Next Step for Emobility

To successfully design cars for e-mobility, companies need to focus on systems engineering. Otherwise, they will be limited to time-consuming and expensive physical prototypes.

Batteries and brakes are complex systems to begin with. Once you realize they are subsystems of the electric powertrain, they become even more complicated.

Oswald says, “Using systems simulation, we can model what happens to each subsystem under different scenarios, weather and driving conditions. You can then gain insights into how the whole system will behave when they all run together.”

An engineer works to optimize a battery system. But to optimize

this subsystem in the context of the whole, engineers will need systems

simulations or expensive physical prototypes.

Despite the potentials of systems simulation, some companies are struggling to keep up with this new design philosophy.

He adds, “Many are still business as usual. If they remain this way, they won’t be competitive. Their time to market will increase while the competition will get faster. That competition will also be able to optimize every system of their product under several conditions. That can’t be done by optimizing on a part-by-part basis. By integrating systems simulation into the design cycle, companies can reduce iteration loops to save time and money.”

Schloter agrees, stating,“When engineers see the effects of using systems simulation for the first time, they are convinced. The main reason companies employ it is to get ahead of their competition.”

To learn how to simulate e-mobility battery systems, watch the webinar: VW Motorsport Presents: Battery Simulation - An Essential Technology for the ID. R at Nürburgring and the Record at Pikes Peak.