TOPIC DETAILS

What is an EV Powertrain?

An electric vehicle (EV) describes a vehicle that relies on electric power for motion. This power is typically delivered by either a battery (BEV) or a fuel cell (FCEV). An EV powertrain refers to the system in an electric vehicle that converts electrical energy into mechanical motion.

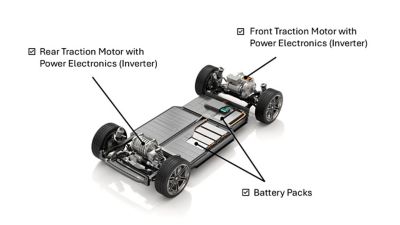

An EV powertrain consists of:

- An energy storage system — a battery or fuel cell

- Power electronics — inverter/converter with associated controls

- An electric machine — energy conversion system (electric motor)

- A mechanical system — a transmission system

Of note, an EV drivetrain also includes the driveshaft and its mechanical parts. In addition, EV powertrains do not produce emissions during operation, helping to provide a greener method of transportation.

What is a Powertrain?

A powertrain is a set of components inside a vehicle that generates and controls power to thrust the vehicle into motion.

Battery electric vehicles (BEVs) are becoming the standard for electric vehicles. They accounted for 70% of the global electric car stock in 2023 and 98% of electric light commercial vehicle sales in 2022 due to their simpler designs and lower maintenance costs.

A BEV powertrain integrates a battery pack to store electrical energy; inverters for power conversion to drive electric motors; an electric motor that converts electrical energy into mechanical motion, also known as the prime mover; and a gear box that controls the output from the motor to the wheels.

Compared to an internal combustion engine (ICE) that requires an engine, fuel injection systems, and exhaust systems, an EV powertrain is a different architecture that produces zero tailpipe emissions and no ICE noise. With fewer moving parts, there is less wear and generally lower upkeep costs, as high-maintenance items such as spark plugs and oil changes are no longer required.

Key Components of EV Powertrains

As the world strives for a more sustainable future, the benefits of electric cars have become well-known. While batteries are key components in electric vehicles, there is a collection of power electronic components and controls orchestrating the flow of electricity behind the scenes.

In fact, power electronics are a critical part of EV powertrain systems. They help ensure optimal energy conversion, as well as the optimal operation, safety, and performance of electric vehicles.

Power Generation Systems in EV Powertrains

Power generation systems provide the electrical power needed to move the vehicle.

Battery pack: The battery pack incorporates numerous cells (typically lithium-ion cells) that serve as the primary energy storage mechanism. Lithium-ion cells have a high energy density and are able to store a large amount of energy per unit of volume. Fuel cells are another type of energy storage.

The battery pack also incorporates a battery management system (BMS), providing strategies that prevent overcharging or discharging to ensure the safe operation of the battery.

Onboard charger: The onboard charger converts alternating current (AC) power from an external charging source (the grid) to direct current (DC) power for storage in the battery. The onboard charger communicates with the vehicle control unit and external charging station to regulate power delivery. It may also include cybersecurity features.

Power Distribution Systems in EV Powertrains

Power distribution systems control the power from the electrical power source. They integrate power electronic components, including inverters that convert DC power from the battery to AC power for use by the motor. Different power electronic controls topologies can also help increase performance by offering different inverter switching strategies to, for example, increase efficiency or achieve maximum torque.

DC-to-AC inverter (traction inverter): The DC-to-AC inverter transforms DC power from the battery to AC power, producing the alternating voltages required to control the motor’s speed and acceleration. DC-to-AC inverters incorporate insulated-gate bipolar transistor (IGBT) or silicon carbide metal-oxide-semiconductor field-effect transistor (SiC MOSFET) power devices connected by an array of printed circuit boards (PCBs) and/or busbars. These power semiconductor devices behave as high-speed switches, turning high levels of current and voltage “on” and “off” to the electric motor, simulating a sinusoidal current waveform.

DC to DC converter: The DC-to-DC converter adjusts the battery’s high-voltage DC output to supply the low-voltage DC needed to power auxiliary systems such as the lighting, entertainment system, or air conditioning. It integrates power electronics, including power semiconductors, diodes, capacitors, and magnetics. A DC-to-DC converter may also be integrated into a power delivery module (PDM) that includes a charger and junction box.

Vehicle control unit: The vehicle control unit is the central communication hub of an EV, gathering and processing data from various systems, sensors, and controllers. It synchronizes activities between the onboard charger, battery, motor, and other systems.

Power distribution unit: The power distribution unit ensures that each system within the vehicle receives the right amount of power. It integrates power electronics such as switches, fuses, relays, and occasionally semiconductor devices, preventing system overloads and enabling efficient operation.

Firmware and ECUs: The efficient and safe operation of EV powertrain components is orchestrated by a collection of electronic control units (ECUs) powered by firmware, ensuring the efficient exchange and processing of data.

Thermal management system: The thermal management system shields the battery and motor from extreme temperatures, ensuring efficient and safe processes throughout the EV’s drive systems and ecosystems.

Electro-Mechanical Energy Conversion in EV Powertrains

Traction motor: The traction motor is the principal component responsible for generating road traction and propelling the vehicle forward. It typically consists of:

- Stator: The stationary part of the motor, which consists of magnetically permeable steel laminations with copper coils wound in slots circumferentially spaced around the stator.

- Rotor: The rotating part of the motor, which typically consists of magnetically permeable steel laminations with permanent magnets strategically placed to best interact with the stator design to generate torque. There are other motor topologies that do not require magnets, e.g., an induction machine that uses a “squirrel cage” configuration instead of permanent magnets to generate torque.

As current travels through the stator’s coils, it induces a rotating magnetic field. This field interacts with the rotor’s magnets (or the induction motor’s squirrel cage), causing the rotor to spin and generate motion. The EV’s accelerator pedal controls the amount and frequency of electrical power flowing from the battery to the motor via the control systems and power electronics, thereby controlling the torque produced by the motor.

Most EVs are fitted with an AC motor (either synchronous, as in brushless permanent magnet machines, or asynchronous, as in induction machines).

Gearbox and transmission: As in an ICE vehicle, a mechanical transmission is often needed to match the output of the engine or motor to what is needed at the wheels. An EV gearbox is usually much simpler than the gearbox in an ICE vehicle because an electric motor can produce torque over a much wider speed range than a combustion engine, and it can also produce torque at zero speed. This means that the clutch and the wide gear range typically present in an ICE transmission are not required. However, electric motors are typically designed to rotate at a higher speed than the speed required at the wheels, so the gearbox is used to decrease the speed and increase the torque available.

Most electric vehicle transmissions have a single fixed-gear ratio, with no components required to change gear ratio. Multispeed gearboxes can be useful in high-performance or larger commercial EVs to extend the torque and speed range available.

In an HEV powertrain, the gearbox plays a crucial role in combining power from one or more motors and the engine, using conventional or planetary gear sets. Depending on the driving conditions, this gearbox will work with the motors and engine to deliver power in the most efficient way, which can include operating the vehicle without the internal combustion engine running, as well as recharging the battery by using the engine and the motors in generating mode when driving conditions are suitable.

The differential is normally integrated as part of the gearbox in electric vehicles, or, depending on the powertrain layout, it can also be a separate component.

Types of Electrified Powertrains

There are three main types of electrified powertrains, providing distinct configurations and functionalities and catering to different needs and preferences.

Battery electric vehicles (BEVs): Also called pure-electric vehicles, BEVs derive all their power from the energy stored in their rechargeable battery packs. They do not use a secondary energy storage source such as a fuel tank.

BEVs must be charged from an external source, and today’s driving ranges vary between 100 and 400 miles (about 160 to 640 km). In some cases, this range is higher in high-end EVs. Examples of BEVs include the Tesla Model 3, Nissan LEAF, and BMW i3, with many new models having recently appeared on the market.

Hybrid electric vehicles (HEVs): HEVs combine an internal combustion engine with an electric drivetrain, achieving improved fuel economy and performance when compared to a conventional ICE vehicle.

HEVs are powered by electricity to varying degrees. Hybrid electric cars incorporate a variety of beneficial features, such as:

- Regenerative braking that converts kinetic energy back into electrical energy for storage in the battery (also shared with BEVs)

- Start-stop systems that shut down the engine when idle, which reduces emissions

- An electric generator (powered by the ICE) that recharges the battery or provides additional power to the electric motor

Today’s HEVs have driving ranges varying between 400 and 600 miles (about 640 to 960 km). With the exception of PHEVs, HEVs are typically not charged from an external source. Examples of HEVs include the Ford Fusion Hybrid, Toyota Camry Hybrid, and Honda Civic Hybrid.

Plug-in hybrid electric vehicles (PHEVs): PHEVs (a subclass of HEVs) can be charged from an external source. They have a driving range today that varies between 20 and 50 miles (30 to 80 km) on electricity alone, making them ideal for short city trips. For longer journeys, PHEVs can rely on gasoline or diesel. Examples of PHEVs include the Toyota Prius Prime, Chevrolet Volt, and Honda Clarity.

The fuel cell electric vehicle (FCEVs) is a fourth type of electric vehicle. They work by producing electrical current from hydrogen fuel cells instead of batteries.

ICEs vs. EV Powertrains

Internal combustion engines have been the main source of power in vehicles for over a century.

Despite their longstanding use, ICEs present several challenges, not least of which is the environmental pollution resulting from their burning of fossil fuels. Consequently, there has been a concerted effort by governments and individuals towards the adoption of electrically powered vehicles.

As a point of comparison, here are the key differences between ICE and EV powertrains:

Key Aspect | ICE Vehicle | Electric Vehicle |

Powertrain | Includes the engine, multispeed transmission, fuel system, and exhaust system | Consists of a battery, inverter and controls, electric motor, and transmission |

Prime Mover | Internal combustion engine | Electric motor |

Energy source | Fossil fuels | Battery, fuel cell |

25-36% | 80-85% | |

Environmental impact | Greenhouse gas emissions | Reduced environmental impact due to zero or reduced (for HEV) tailpipe emissions |

Advantages of EV Powertrains

The advantages of EV powertrains vary according to individual driving habits and preferences, and proximity to a charging station infrastructure. Here are the main advantages of electric vehicle powertrains:

- Zero emissions: In the context of reducing pollution and greenhouse gases, perhaps the most significant advantage of BEV powertrains is the absence of tailpipe emissions caused by the burning of fossil fuels and a reduced carbon footprint over the lifetime of the BEV.

- Reduced noise pollution: In addition to the absence of greenhouse gas emissions, BEV powertrains also generate less audible noise, contributing to a quieter environment.

- Energy efficiency: BEV powertrains are significantly more energy-efficient than ICE powertrains, converting over 80% of stored energy into motion. Also, features such as regenerative braking enable the recycling of energy.

- Lower maintenance costs: With fewer moving parts, maintenance costs of EV powertrains are lowered and the battery life, in ideal conditions and proper care, could last as long as 12 years. Like any other battery, it will lose its capacity over time.

- Lower fuel costs: The cost of electricity to power a BEV is typically lower than the cost of gasoline or diesel for an ICE vehicle. It costs more than twice as much to fuel a gasoline-powered vehicle than an EV in the United States, according to a study done by the University of Michigan.

- Lower total cost of ownership (TCO): Although BEVs typically present higher upfront purchase costs, savings on fuel and maintenance contribute to a lower TCO, making them cheaper to run over the vehicle's lifetime.

Disadvantages of EV Powertrains

EV powertrains also present several disadvantages, including:

- Cost: As it stands, electric vehicles require a higher upfront investment than ICE vehicles due to the higher cost of powertrain components (mainly the battery).

- Charging time: Battery charging time typically takes anywhere from 30 minutes to several hours depending on the charging capacity of the charging station, compared to the few minutes it takes to fill up the tank of an ICE vehicle.

- Consumer range anxiety: Currently, BEVs receive a limited driving range from a single charge. Because the charging stations are not as widespread as gas stations, and batteries take a longer time to charge, consumers have anxiety about taking long trips with a BEV.

EV Powertrain Design

EV powertrain designs principally aim for efficient thermal management and increased driving ranges. They favor increased power density (power delivered per unit volume), striking a delicate balance between power generation and heat dissipation. EV mileage, efficiency, and overall performance may be optimized at the component, system, and architectural levels.

For example, vehicle performance is significantly improved by incorporating driving modes into the drive system architecture, enabling multiple configurations based on driving conditions.

ECUs integrated into the hardware’s architecture provide augmented functionalities — for example, converting throttle instructions from the driver into instructions for the motor and battery, meeting specific requirements like 0- to 60-mph acceleration, and optimal energy consumption. These ECUs are powered by algorithms such as dynamic programming or consumption minimization strategies.

The Future of EV Powertrains

In the push for electrification, the EV powertrain is an exciting innovation bringing enhanced benefits in efficiency, eco-friendliness, and performance. As more consumers switch to EVs, there will be a greater diversity of models appearing on the market, from SUVs and luxury cars to trucks and more.

Ansys stands at the forefront of this technological revolution, supporting the advancement of clean technology solutions that are transforming the way the world uses its energy in the best way possible.

Ansys ConceptEV® software is a design and simulation platform that enhances the performance of the entire EV powertrain system. It enables cross-functional engineering teams to connect component models and evaluate vehicle-level requirements, enabling fast and accurate decision-making throughout the development process and integrating:

- Multi-fidelity component models

- Embedded control algorithms

- Integration with component design tools

- Powertrain capability simulation

- System trade-off quantification

To help your engineers deliver more energy-efficient powertrains and meet target costs, get a free trial of Ansys ConceptEV software. Or view a demo of how ConceptEV software enables you to enhance electric vehicle powertrain efficiency and performance.