-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

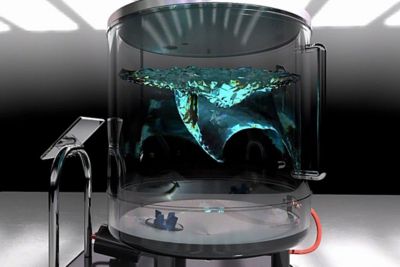

Model the Mixing Process and Blending of Fluid-like Materials

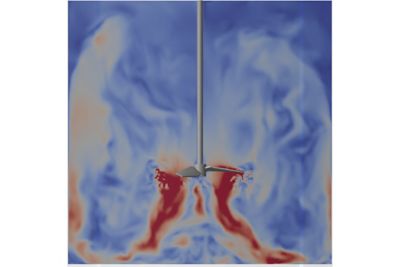

Acting as a virtual protype, a mixing model can help you understand, predict and improve performance across a wide range of applications. Tanks, liquids and mixing processes vary across applications and industries. Simulation helps to evaluate different tank configurations, impeller types and orientations, liquid levels, operating conditions and various fluids.

-

Automated Mixing Guided Process Template

-

Multiphase, Free Surface and Population Balance models

-

Scale-Up and Scale-Down

-

Reduced Order Modeling Capabilities

Increase Product Uniformity

Ansys Simulation tools accurately predict final mixture compositions. Make adjustments prior to prototyping to meet your quality targets.

Reduce Operating Costs

Analyze your mixing method to optimize productivity, enabling you to produce more efficiently and save time.

Product Performance

With simulation, you can predict systems performance and assess the mixing process. Validate design work faster with Ansys.

Enhance Vessel Performance

With simulation, you gain better insight to how your vessel reacts to mixing and predict how it handles pressure and thermal loads.

Featured Products

“The incorporation of Ansys into our work at USC’s Rocket Propulsion Lab has helped our team forge ahead with new confidence and new sophistication into projects that just years ago we thought were out of reach. Beyond its technical contributions, using Ansys simulation software has also encouraged RPL members to gain a deep understanding of engineering analysis, developing them into some of the best engineers to graduate from our nation’s universities.”

Fast, Accurate Solutions for Mixing Tanks

In the past, mixing simulation was a difficult task that was often regarded as an art form, rather than a science. Today, the Ansys portfolio contains CFD software that provides highly accurate mixing simulation. Virtual prototyping gives engineers a huge advantage by allowing them to quickly develop and validate their mixing equipment and processes in a streamlined workspace.

Simulation Solutions

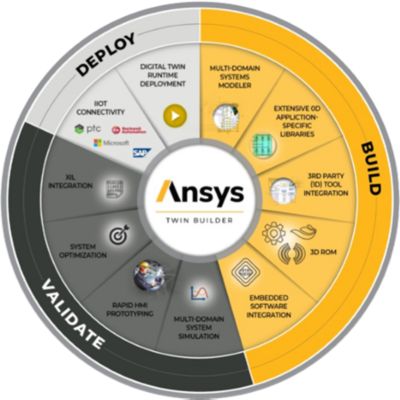

Ansys Product Solutions for Mixing Tanks

Due to the wide variety of tank geometries and mixing conditions, including rpm, rheology and more, Ansys has developed a streamlined portfolio of compatible simulation software for mixing tanks. The combination of these tools provides in-depth analysis applicable to a wide variety of industries including:

- Pharma

- Chemical processing

- Consumer goods

- Food processing

- Oil & gas

Featured Resources

BLOGS

Let’s Get Started

If you're facing engineering challenges, our team is here to assist. With a wealth of experience and a commitment to innovation, we invite you to reach out to us. Let's collaborate to turn your engineering obstacles into opportunities for growth and success. Contact us today to start the conversation.