-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

DATE: 6/24/2024

PRESS RELEASE

Ansys Joins Intel Foundry’s United States Military, Aerospace, and Government (USMAG) Alliance

Ansys is developing thermal management technology for the Intel 18A silicon process to enable HPC, graphics, and AI products supporting U.S. national security applications

Key Highlights

- Ansys joins the Intel Foundry Accelerator United States Military, Aerospace, and Government (USMAG) Alliance to deliver secure design methodologies and flows for U.S. security applications

- Ansys deepens its technical collaboration with Intel Foundry – enhancing Ansys Redhawk-SC™ to deliver a comprehensive thermal management flow for the Intel 18A advanced process technology to enable reliable, high-performance chip design

PITTSBURGH, PA, June 24, 2024 – Ansys (NASDAQ: ANSS) today announced it is joining the Intel Foundry Accelerator USMAG Alliance to support the design of secure and efficient chips for national security and government applications. Through this alliance, Ansys’ semiconductor simulation tools will be optimized to deliver secure design methodologies and workflows to meet the requirements of Intel Foundry’s process design kits (PDKs) — essential to fully achieve the requirements of military, aerospace, and government applications.

Ansys is deepening its technical collaboration with Intel Foundry by developing an enhanced thermal management flow with the RedHawk-SC platform, supporting the Intel 18A silicon manufacturing process. Intel 18A features revolutionary backside power delivery technology, PowerVia, that comes with new challenges for effectively cooling circuits, especially for high-performance computing, artificial intelligence (AI), and graphics processor chips. Ansys’ mature and well-proven thermal solver technology provides predictive accuracy and the capacity for full-system analysis, resulting in better performance and greater design flexibility.

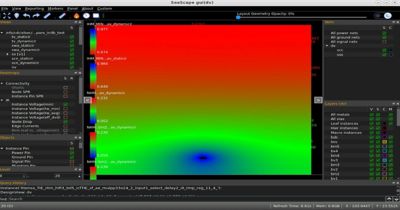

Unveiling precision using power integrity analysis data from Ansys RedHawk-SC

In addition, Intel Foundry and Ansys are collaborating to deliver signoff verification of thermal and power integrity and mechanical reliability of Intel’s embedded multi-die interconnect bridge (EMIB) assembly technology. These capabilities span use-cases ranging from advanced silicon process nodes to various heterogenous packaging platforms.

“Ansys has worked with Intel Foundry to address complex multiphysics challenges and meet stringent thermal, power, mechanical, and reliability requirements,” said John Lee, vice president and general manager of the electronics, semiconductor, and optics business unit at Ansys. “Ansys’ deep background in physics simulation addresses the very advanced requirements of military and aerospace products. Thanks to the collaboration between our companies, we can deliver greater value to our mutual customers.”

“Intel Foundry welcomes Ansys as a valuable addition to our USMAG Alliance,” said Suk Lee, vice president & general manager, ecosystem technology office, Intel Foundry. “With Ansys, we now have an ecosystem of partners that can provide robust design and simulation capabilities to the MAG community for securely developing semiconductor solutions with Intel’s leading-edge process capabilities.”

About Ansys

Our Mission: Powering Innovation that Drives Human AdvancementTM

When visionary companies need to know how their world-changing ideas will perform, they close the gap between design and reality with Ansys simulation. For more than 50 years, Ansys software has enabled innovators across industries to push boundaries by using the predictive power of simulation. From sustainable transportation to advanced semiconductors, from satellite systems to life-saving medical devices, the next great leaps in human advancement will be powered by Ansys.

Ansys and any and all ANSYS, Inc. brand, product, service and feature names, logos and slogans are registered trademarks or trademarks of ANSYS, Inc. or its subsidiaries in the United States or other countries. All other brand, product, service and feature names or trademarks are the property of their respective owners.

ANSS-T

See What Ansys Can Do For You

See What Ansys Can Do For You

Contact us today

Thank you for reaching out!

We’re here to answer your questions and look forward to speaking with you. A member of our Ansys sales team will contact you shortly.