-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

ANSYS BLOG

November 11, 2017

Chinook ETS Wind Powered Car Breaks World Record with the Help of Ansys

Chinook ETS is a team of student engineers from École de technologie supérieure in Montreal, Canada. We are trying to design and build a prototype wind-powered car with the highest possible efficiency for the Racing Aeolus event held in Den Helder, Netherlands.

Our goal is not only to perform well during the race but also to develop efficient wind turbines through numeric simulations, new composites fabrication processes, advanced electronics and out-of-the-box thinking. Ansys simulation solutions play a key role in our design efforts.

Racing Aeolus comprises three different segments: the main event, during which wind-powered cars must race on a 500-meter track against the wind as fast as possible; a drag race; and the Gerard Broers innovation award. During the main event, the vehicle’s efficiency is calculated by dividing its speed by the average wind speed over the track’s length. In the drag race, cars race against each other to determine which has the fastest acceleration over 100 meters. Finally, after these speed tests, each team votes to determine who receives the Gerard Broers innovation award. The team that performs best overall wins the Racing Aeolus Cup.

For 2016–2017 we designed a brand new platform for our seventh and latest prototype. The previous platform produced incredible results, but it had reached its limits in terms of efficiency, aerodynamics and available space after five iterations. The new lighter, stronger design had to fit the front wheel inside the car body, create less aerodynamic drag and provide space for future upgrades.

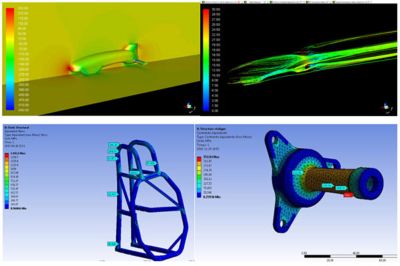

We used Ansys simulation solutions extensively in this project. Ansys FLUENT flow simulation was used to optimize the shape of the carbon fiber monohull. Once the shape design was frozen, Ansys Composite PrePost(ACP) was used to simulate the load case and fiber placement in the car body, enabling us to reduce the weight from 22 kg (old car body) to 16 kg. Ansys Mechanical was used to simulate many structural components and optimize them to reduce the weight. Overall, the new vehicle was 20 kg lighter than its predecessor thanks to hours of Ansys simulation.

The results of more than 10 000 hours of work from the team quickly paid off during the first day of Racing Aeolus 2017. The car performed brilliantly, and we were able to break the efficiency record established by the Danish team a year before, with a score of 102.45 percent of average static wind speed over 500 meters. Unfortunately, this was the only day during which the winds were strong enough to race, so the drag race event had to be canceled. With our new platform and the energy we invested to perfect every detail, we were nominated for the Gerard Broers innovation award.

In the coming year, we plan to further optimize the new platform, especially the wind turbine. Simulations will be done for all the major structural parts of the car to minimize the weight. As for the carbon fiber monohull, we plan to review the fiber placement to improve the composite’s drapability and reduce material losses during the layup.

To learn more about Chinook ETS, find us on Facebook or check our videos on YouTube.