-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

Signal integrity and power integrity (SI/PI) are critical aspects of high-speed electronic design, ensuring that high-speed data — such as serializer/deserialize) (SERDs) and double data rate (DDR) memory interfaces — are transmitted accurately and reliably. With the increasing complexity of modern electronic designs, achieving robust SI/PI performance has become more challenging than ever. However, the adoption of automation in SI/PI design — particularly through Python-based libraries like PyAEDT — has revolutionized the workflow, bringing significant benefits to the industry.

1. Accelerated Design Iterations and Reduced Engineering Time

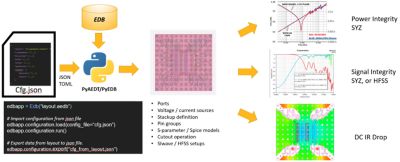

One of the most significant benefits of automation in SI/PI design is the acceleration of design iterations, leading to a substantial reduction in the engineering time required to set up electromagnetic (EM) simulations. EM simulations are essential for predicting SI/PI performance accurately, but they often require a complex and time-consuming setup process. Engineers must define numerous parameters, including port definitions, stack-up and material properties, boundary conditions, cutout frequency sweeps, and more. These tasks, when performed manually, are not only labor intensive but also error prone.

Automation offers a solution to this challenge, compressing simulation setups from minutes or hours to few seconds depending on the complexity of the design. By scripting the setup process, engineers can reuse validated settings across multiple design iterations, ensuring consistency and accuracy. This approach minimizes the number of manual steps required, reduces the likelihood of errors, and significantly speeds up the simulation process. Engineers no longer need to worry about missing inputs or incorrect configurations, as the automation scripts ensure that the setup is consistent and correct every time.

Moreover, the time saved by automating these repetitive tasks enables engineers to focus more on exploring and analyzing simulation results. This shift in focus from setup to analysis not only enhances productivity but also enables deeper insights into the design’s performance, leading to better design decisions.

2. Streamlined Geometry Creation for Pre-layout and Parameterization of Post-layout Design

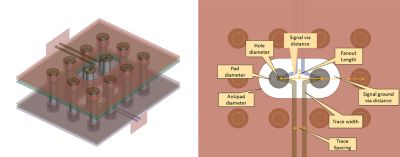

Another key benefit of automation in SI/PI design is the ability to easily create, modify, and parameterize layout primitives. When importing a layout into Ansys Electronics Desktop (AEDT) electronics systems design platform, engineers often need to parameterize various aspects of the design and assess the impact of manufacturing variations on performance.

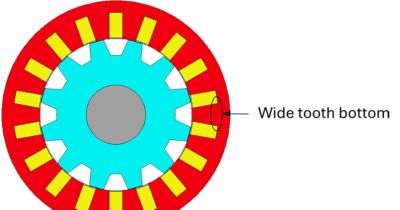

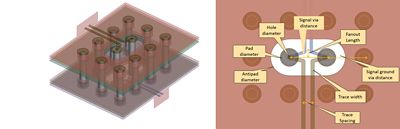

For example, in a high-speed serial link design on a 20-layer PCB, engineers may need to evaluate the effects of critical via interconnects to minimize impedance mismatch, from DC to several tens of GHz. Non-optimal via design can cause high return loss, and significantly impact the channel performance. Achieving a low return loss signal via requires understanding the impact of vias padstacks such as anti-pad sizes, pad sizes, and via barrels.

Manually parameterizing and analyzing these features across numerous transmission line sections can be extremely time-consuming and prone to errors. However, with the use of automation, these tasks can be completed in a fraction of the time. PyAEDT enables engineers to access the Ansys Electronics Data Base (EDB) API and script the parameterization process, enabling them to quickly modify geometry and assess the impact of manufacturing tolerances on performance. This capability not only speeds up the design process but also enables comprehensive design variation exploration, leading to more robust designs.

By automating the parameterization and analysis of design features, engineers can efficiently explore a wider range of design possibilities, optimize performance, and ensure that the design meets manufacturing requirements. This streamlined approach reduces the risk of costly design errors and improves overall design quality.

3. Minimizing Risk Before Tape-out and Production

The third major benefit of automation in SI/PI design is the minimization of risk before tape-out and production. In the electronics industry, mistakes made during the design phase can lead to costly rework, delays, and even product failures. As designs become more complex, the need for rigorous validation and standardization becomes increasingly important.

Automation tools like PyAEDT play a crucial role in minimizing these risks by enabling better standardization and productivity in the design process. Automated workflows ensure that established processes — such as importing designs, preprocessing, meshing, solver setup, and post-processing — are followed consistently and correctly. This consistency reduces the likelihood of errors and ensures that the design is validated thoroughly before moving to the production stage.

Moreover, automation enables the development of more complex workflows that can be reused across multiple projects. Engineers can create standardized scripts that encapsulate best practices and proven methods, making it easier to deploy these workflows across different teams and projects. This standardization not only improves productivity but also ensures that the design process adheres to industry standards and best practices.

By minimizing the risk of errors and ensuring consistent, high-quality designs, automation helps to reduce the likelihood of costly design revisions and delays, leading to more successful tape-outs and production runs.

The adoption of PyAEDT automation in SI/PI design has brought significant benefits to the electronics industry. By accelerating design iterations, reducing engineering time, streamlining geometry creation, and minimizing risks before tape-out and production, automation has become a notable change in the field. It has democratized the simulation process, making it accessible to a wider range of users, and has enabled the development of more complex workflows and recurring tasks. As the industry continues to evolve, the role of automation in SI/PI design will only become more critical, driving further innovation and efficiency in the design process.

Learn more about how PyAEDT can help with your electronics automation.

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.