Put simply, radiation is the flow of energy in the form of electromagnetic waves or high-speed particles. While radiation — such as visible light — is part of our daily lives, space radiation poses unique challenges to those in the aerospace field.

According to NASA, “space radiation is comprised of atoms in which electrons have been stripped away as the atom accelerated in interstellar space to speeds approaching the speed of light — eventually, only the nucleus of the atom remains.” This radiation can breach the exterior of a satellite and reach its electronic components, causing immediate and cumulative effects, including the potential for complete satellite failure.

This longstanding challenge may also become more prevalent in the future. “The rapid growth of the small satellite (SmallSat) market in recent years has led to the increasing use of commercial off-the-shelf (COTS) electronic components to reduce costs,” says Kyung Ryeung Min, founder and CEO of Space & Bean. “However, COTS components are at risk of malfunctioning or being damaged in the radiation environment of space.”

Min founded Space & Bean to address this issue and help create a safer tomorrow. To achieve this objective, Space & Bean develops advanced composite materials and shielding technologies to protect COTS components in SmallSats and enable reliable use in the harsh space environment.

This ambitious goal requires a specific type of company model that is collaborative and not competitive. “Space & Bean aims to provide differentiated value by developing technologies that can create synergies with other companies,” says Min. “We aim to have unique technology and quickly capture the market rather than compete.”

As part of this mentality, Space & Bean views customer trust as an opportunity to expand its technology, says Min. The company relies on this trust and collaboration to constantly evolve and tailor its technology to fit customer needs. One such customized product created to aid customers is SCUTUM R.

Protecting SmallSats With Advanced Shielding Technology

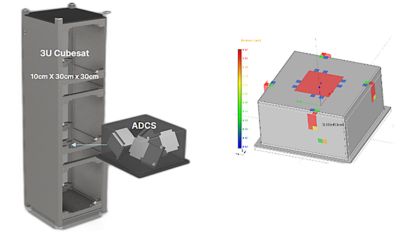

Space & Bean developed the SCUTUM R shielding solution to reliably protect COTS components on SmallSats from space radiation. However, SCUTUM R is not just a static product; it’s a more customized, comprehensive solution than is typically found in the market, according to the company.

“While shielding material companies typically focus on developing and supplying materials with the performance requested by customers, we differentiate ourselves by going beyond material development to design and manufacture optimal protection solutions based on our shielding technology,” says Min.

For SCUTUM R, this means that Space & Bean offers not only composite materials and radiation-shielded boxes for COTS but an independent space environmental analysis service for commercial parts via its fast radiation impact detection and yield (FRIDAY) service.

In particular, Min shares that a few of SCUTUM R’s key benefits are:

- Ensuring maximized space radiation and shielding performance. This is achieved by analyzing the space radiation environment and developing customized shielding materials and structures to minimize the effects of radiation.

- Offering a lightweight design that is optimized for even the smallest satellites without sacrificing shielding ability. “This is key to improving the reliability of satellites and extending their lifespan,” says Min.

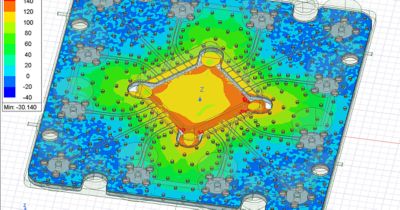

- Providing customized, flexible designs that can adapt to various satellite systems. This involves performing a radiation impact analysis to determine what composite materials should be applied to the shielding box design.

- Forming international partnerships to prove trustworthiness and performance. “We are currently working with Japanese and American companies to secure global-level reliability and customize the size, shape, and performance to be applied to various satellite systems,” says Min.

Before these benefits can be actualized and SCUTUM R can be deployed, Space & Bean needs to design, develop, and optimize its unique technology. To achieve this, Space & Bean turns to Ansys simulation software.

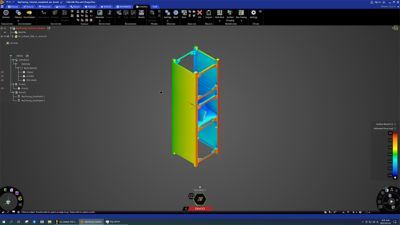

A model of a radiation shielding box for commercial parts with an attitude determination and control subsystem (ADCS) (left) and a radiation impact analysis that is used to ensure commercial component reliability for an extended satellite lifetime (right).

From Simulation to Optimized Radiation Shield

When deciding what software to use throughout the design and development process, Space & Bean — a member of the Ansys Startup Program (Korean page) — opted for Ansys software for a few reasons. “Ansys analysis results are recognized as reliable and internationally validated, so it was a natural choice for Space & Bean to adopt Ansys solutions to enhance the reliability of our data,” says Min. “We were confident that Ansys would not just be an analysis tool but an important foundation for our technology to be recognized in the global market.” Additionally, Min shares that the ability to expand business to analyze both space radiation and electromagnetic wave analysis with the support of the Korean government was also a major benefit of partnering with Ansys.

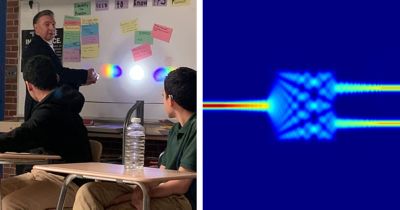

One way the team used simulation software was for its space radiation impact analysis, which involves studying the effects of space radiation based on a specific satellite’s mission, lifetime, and orbit. This information can then be used to determine the optimal protection strategy and structural shielding design, including the ideal locations to place radiation-sensitive electronic components to minimize radiation effects. Here, Space & Bean used Ansys Charge Plus electromagnetic charging and discharge simulation software “to analyze the electrical effects of plasma and electrons during space radiation and to design the geometry of the metal housing and the system for discharge in the subsystem design,” says Min.

Ansys Charge Plus software

The team also relied on Ansys EMC Plus electromagnetic interference and compatibility simulation software in its design process. “EMC Plus software has become powerful for analyzing the effects of electromagnetic waves around induction coils in the conceptual design of wireless power transmission systems and for checking the results of designing the thickness and connection of metal thin films in composite housing designs,” says Min.

No matter the specific software used, performing a “preliminary analysis with Ansys simulation before a product is built helps us reduce production costs and development time,” says Min. “Modeling and simulation software has reduced the time required for design and testing by more than 30%, and (we are) currently targeting a reduction of more than 50%, which is expected to have a positive impact on the development schedule going forward.”

Using Ansys simulation results, Space & Bean can better attain its goals by efficiently creating custom composite shielding boxes that increase the durability of COTS components and block space radiation. Looking ahead, “we will continue to actively utilize Ansys simulation to provide precise analyses and reliable data,” says Min. As part of this, Space & Bean is considering using additional simulation software to increase efficiency across its portfolio, which consists of four brands. For example, because thermal analysis is a key factor in the space industry and is tied to Space & Bean’s ongoing technological development, the company is investigating introducing Ansys solutions in this area.

An Ansys simulation analysis of a satellite’s operating environment and conditions, including space radiation levels (left); a 3D model predicting the radiation vulnerability of SmallSat components (middle); and an impact analysis of various space electrons and ions in a plasma environment (right).

What’s Next for Space & Bean

With SmallSats becoming more popular, the company’s technology evolving, and an entrance into overseas markets imminent, Space & Bean is on the precipice of enormous growth.

At this crucial moment, Min emphasizes how the company’s core goals remain the same: providing optimized, usable, and proven products that address the real-world problems faced by its customers.

For the space industry, this means that Space & Bean is continuing to provide shielding technology to enhance SmallSat reliability and trusted data analyses via simulation that can be used by the global market and organizations like the ESA and NASA. Additionally, Min shares that Space & Bean is developing its own space components that use its radiation protection technology.

Space & Bean is also extending this mentality outside of the space industry to develop reliable protective technologies for other extreme environments, such as those seen in the automotive, defense, semiconductor, and medical fields. This will involve continuing to foster partnerships with customers “to ensure that all of the advanced technologies that humankind utilizes operate more safely and sustainably,” says Min. “As technology advances and reliability becomes more important, we will continue to grow and play a significant role in the global marketplace with our differentiated protection solutions.”

This growth will also extend beyond Space & Bean too. Min shares how the South Korean government and Ansys are working together to support startups and introduce them to simulation programs.

“In order for Korean companies to continue to develop and grow their technology, I would like to see more support programs that allow them to utilize simulation programs,” says Min. “I believe that more opportunities like this will ease the burden on companies and allow them to focus on research and development more efficiently. In the end, I think this will lead to more innovation in the space industry.”

Learn More

Discover the benefits of the Ansys Startup Program.

Just for you. We have some additional resources you may enjoy.

“Modeling and simulation software has reduced the time required for design and testing by more than 30%, and (we are) currently targeting a reduction of more than 50%, which is expected to have a positive impact on the development schedule going forward.”

— Kyung Ryeung Min, founder and CEO, Space & Bean