-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

ANSYS BLOG

January 19, 2024

Permanent Magnetic Latching: Keeping Your Electronics Secured

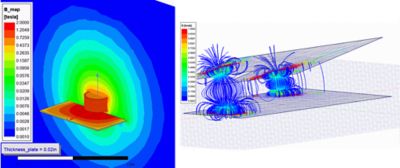

Permanent magnets are materials where the magnetic field is generated by the internal structure of the material itself. A basic consideration for designing a permanent magnet latching mechanism is to ensure that the magnets are designed to provide an appropriate latching force. The magnetic force between two permanent magnets is dependent on several factors, such as the separation distance between the two magnets, size of the magnets, and material of the permanent magnet itself. A low-frequency electromagnetic field solver like Ansys Maxwell can help engineers run sizing and material studies to optimize the force in latching mechanisms while reducing the cost of the magnetic latch, as rare earth magnets are expensive.

Figure 1. Material and sizing studies in Ansys Maxwell

Devices that Use Permanent Magnets

Wireless chargers and smart screen covers for phones, tablets, watches, virtual reality (VR) devices, magnetically latching wall-mount security cameras, and countless electronic devices in day-to-day life rely on permanent magnets for providing the magnetic attaching mechanism.

For some applications, such as mounted security cameras, permanent magnets replace mechanical fasteners, such as screws and bolts. For other applications, such as wireless chargers, the magnets ensure the optimal alignment of receiver and transmitter for faster charging. In every case, well-designed magnetic attachments for electronics enhance the user experience.

Let’s go over some key considerations in the design of magnetic latches.

Force in Magnetic Latching Mechanism

Presence of ferromagnetic materials, such as soft steels, in addition to permanent magnets, will influence the force of the magnetic latching mechanism. Because of the variables introduced by using ferromagnetic materials and permanent magnets together, it is important to model ferromagnetic shunts and flux concentrators for accurate force computation.

Ferromagnetic steels are known to saturate under certain operating conditions due to a strong magnetic field. Saturation in a latching mechanism is not desired because it will limit the magnetic force and cause stray flux that can interact with Hall sensors (which detect magnetic fields) in the vicinity of the latch. For example, a soft steel shunt may not be saturated where there is a large separation distance between the magnet assemblies. However, as the magnets latch and the separation distance between the magnets becomes small, the soft steel shunt may saturate due to a higher magnetic flux density. In a similar way, the thickness of the soft steel shunt will also influence saturation.

Maxwell can capture saturation in magnetic latching devices that employ ferromagnetic steels and provide an accurate magnetic field and force solution.

Figure 2. Saturation is ferromagnetic materials (left) and stray flux visualization (right)

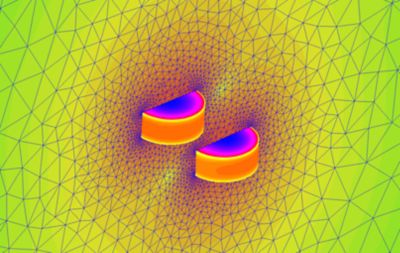

Resolution: Convergence is the Key

A key element to obtaining an accurate field solution from a finite element solver is the mesh resolution. Special consideration should be given to the distribution of mesh elements to capture separation distance and saturation effects. Maxwell automatically generates an initial mesh and adaptively refines it to reach user-defined convergence criteria, ensuring an accurate solution.

Figure 3. Automatic Adaptive Meshing for ease of use and accurate solution

How Does Temperature Change Affect the Magnetic Latch?

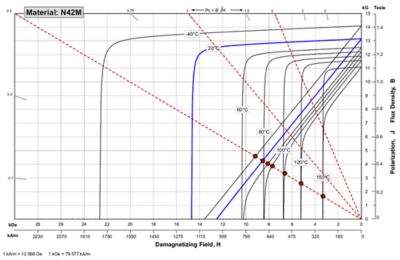

One of the challenges for engineers designing magnetic latches is to obtain material properties, such as B-H curves, for permanent magnets and ferromagnetic steels. Having access to adequate material libraries enables engineers to run material sweeps and study temperature effects on magnetic latch performance, as permanent magnets have different material properties at different temperatures. Maxwell and Ansys Granta material libraries provide users with access to several vendor libraries for permanent magnets that include B-H curves for different grades of magnets at various temperatures.

Figure 4. Demagnetization characteristics of a N42M permanent magnet at different temperatures

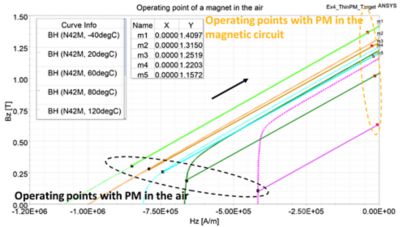

Avoiding Demagnetization in Permanent Magnets and Modeling Hysteresis

Permanent magnets are sensitive to temperature and tend to demagnetize at higher temperatures. Demagnetization results in a deteriorated force performance in magnetic latches. Irreversible demagnetization in permanent magnets under certain operating conditions can lead to failure of magnetic latch mechanisms. Hence, it is important for engineers to take temperature effects into consideration when designing magnetic latches. Figure 5 shows the operating point of an N42 magnet at various temperatures (in air and when placed in a magnetic circuit) based on a study in Maxwell. The results show a larger extent of demagnetization at higher temperatures as seen in the recoil lines.

Figure 5. Operation points indicate demagnetization of a permanent magnet at higher temperatures

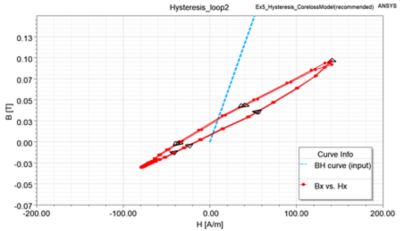

In addition to demagnetization studies, advanced magnetic effects such as magnetization of a virgin magnet and hysteresis effect in ferromagnetic materials can be studied using Maxwell. Hysteresis behavior in ferromagnetic materials results in remanent flux in soft steels when a permanent magnet is removed from the vicinity. The remanent flux can result in a remanent force, which needs to be considered when designing the control of similar devices. Figure 6 shows the vector hysteresis loop traced in a standard 1008 carbon steel object as a permanent magnet recedes from, or moves closer to, the former object.

Figure 6. Magnetic latch with a permanent magnet and ferromagnetic steel (left); hysteresis behavior in ferromagnetic steel as magnet moves closer and farther (right)

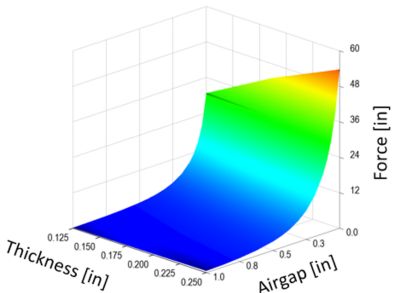

Running Loads of Scenarios to Design the Best-in-Class Magnetic Latch

Running airgap, material, shape, size, and temperature studies will lead to a large design-of-experiments (DOE) space. High-performance computing (HPC) and Ansys Cloud solutions can help engineers to run design variations in parallel and obtain solutions faster.

Figure 7. Response surface from a parametric study in Ansys Maxwell

As illustrated above, Maxwell provides a comprehensive magnetic solution for magnetic latch design that includes:

- Magnetic field and force solution

- Airgap, shape, sizing, and material studies

- Saturation and stray flux effects

- Automated adaptive meshing for ease-of-use and accurate solution

- HPC and cloud solution for DOE studies

- Magnetization and demagnetization analysis

- Vector hysteresis modeling

Understanding Structural Dynamics of the Magnetic Latching Mechanism

In addition to designing the magnetic latch, simulation enables engineers to study the kinematic motion of the magnets during latching and impact stresses by coupling Maxwell with Ansys Motion. Magnetic forces, torques, and position information is exchanged between Maxwell and Motion solvers to compute the structural dynamics of latching mechanisms.

The comprehensive magnetic and multiphysics solutions from Ansys led by Maxwell enables engineers to design robust magnetic latching mechanisms that are fool-proof and enhance user experience, so that you can easily attach accessories like a keyboard, stylus, earbuds, wireless charging transmitter, etc. to your tablet, phone, or other electronic devices.

Watch our on-demand magnetic latching webinar where we explore how design engineers can realize cost savings and improve the performance of magnetic latches by setting up magnet sizing and material studies in Ansys Maxwell. We'll go through the critical design aspects, such as saturation in ferromagnetic materials, advanced magnetic capabilities including magnetization/demagnetization, temperature dependence, vector hysteresis modeling, and complex kinematics/impact prediction.