-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

ANSYS BLOG

November 24, 2020

How HVAC Simulation Can Improve Safety in Public Spaces

In today’s world, engineers and architects increasingly employ engineering simulation so the design of public spaces can meet safety, energy-efficiency and sustainability goals within strict project timelines.

Simulation software is used to create a virtual prototype and calculate the heating, ventilation and air conditioning (HVAC) performance of a building or space. This virtual building design approach leads to:

- A rapid investigation of alternative designs.

- A better understanding of elements that can improve performance.

- Exploration of a more innovative solution.

HVAC simulation has become even more critical over the past year as the global pandemic has affected people and companies all around the world.

As COVID-19 spread, mitigation efforts increased and non-essential businesses were shut down. The highly contagious virus is primarily transmitted in three ways:

- Airborne particles.

- Droplets from a cough or sneeze.

- Touching a surface with infected particles.

Public spaces must consider a variety of strategies to mitigate the spread of airborne diseases for us to return to normal daily routines. You may have read about this in one of our previous blogs, where a CrossFit gym owner had to improve ventilation before safely opening.

Ansys offers various solutions, such as Ansys Discovery and Ansys Fluent, to perform HVAC computational fluid dynamics (CFD) simulations, depending on the level of fidelity needed to help meet HVAC guidelines and standards.

Ansys HVAC Simulation Solutions: Upfront Design Exploration

Discovery can be used to test a variety of different design ideas and concepts, before trying to reach a final, optimized design or building physical prototypes. Discovery has three key capabilities

- Geometry preparation

- Design exploration

- Design verification

Ansys Discovery can help to evaluate and to demonstrate the effectiveness of

new barriers to shield and protect patrons from possible airborne viruses.

You can take the existing ventilation system and the proximity of

tables into consideration.

Geometry preparation in Discovery allows you to quickly create and prepare your model for simulation or create design variations to study. With a single click, you can move into design exploration where you can rapidly explore multiple design concepts with real-time, interactive simulation. After narrowing down design concepts, you can finally move into the refine mode for design verification.

All boundaries, materials and other conditions that were assigned in explore mode will be kept and transferred. A mesh will automatically generate and allow you to refine the whole mesh, or even add in local refinement for areas of interest. When you are ready to solve, refine mode will use the Ansys Fluent solver to give you higher fidelity results.

When more capabilities are needed for your HVAC simulation, transferring your case file to Fluent is only a click away. The ribbon has a transfer button that will pass the model, mesh and conditions directly into Fluent for further verification and optimization.

Design Verification and Optimization

Fluent can perform high-fidelity HVAC simulation for the whole system and components. It will reduce the probability of having to perform in-field design modifications. Regardless of the indoor space you are simulating, Fluent’s industry leading features help you to optimize the following conditions:

- Flow patterns

- Stagnant regions

- Vent location

- Reduction of pathogen spread

The two examples below will show how Fluent was used to evaluate alternative design options and optimize the ventilation of a negative pressure room (NPR). NPRs are used to help contain harmful contaminants in the same room as an infected patient.

The room is maintained at a lower pressure than the surrounding areas. This is achieved by using a ventilation system that exhausts more air than is supplied to the space. The difference in flow rates is made up for with a combination of planned and/or unplanned leakages depending on the air tightness of the room.

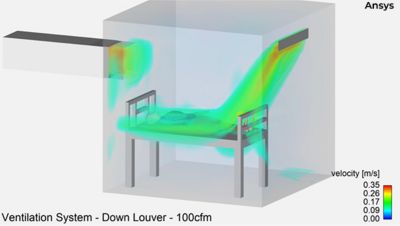

Contaminant Capture Inside an Isolation Unit

Although, staff in the NPR wear personal protective equipment (PPE), it is advantageous to design the ventilation system to minimize the degree to which contaminants from the patient mix and circulate. Three designs with various inlet locations were evaluated to see which design best captures patient contaminants through the exhaust.

- Inlet vent above the door

- Inlet vent in line with the bed

- Inlet vent above the door and in line with the bed

The ventilation flowrate was equivalent to 12 air-changes-per-hour (ACH), consistent with guidelines and standards. Fluent results show that having the inlet vent in line with the bed creates an effective sweeping-like action of the patient contaminants into the exhaust system.

This simulation shows a sweeping-like action to help exhaust patient

contaminants in a negative pressure room.

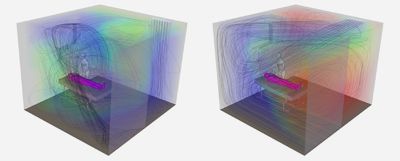

Negative Pressure Room Design Assurance

Fluent can also be used to evaluate the overall NPR design to show the mean age of air (MAA). This is an indication of the freshness of the air and can be related to the ventilation effectiveness. MAA can also be used to help identify stagnant or recirculating regions of air in the ventilated space.

Two cases with the same room dimensions and conditions were examined to find the optimal louver orientation and airflow patterns. Case 1 had the louvers directing air straight down, while case 2 had the louvers directing air towards the patient’s bed.

The results show that case 1, where the louvers were directing the air flow straight down, was the preferred option. The two images below show the flow streamlines and volume rendering, where red indicates regions of higher air residence times.

Case 1 (left) is the optimal ventilation option over case 2 (right). Having the

louvers direct airflow straight down reduces air residence time,

which is shown by the red volume rendering.

Fluent has been used in a variety of other HVAC simulations to help analyze contaminant migration, including restaurants, retail stores, office buildings and airplane cabins. Watch the webinar Simulating Safe HVAC Systems with Ansys Fluent to learn about those case studies in detail and how you can use Fluent to design a safer HVAC system.