-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

ANSYS BLOG

February 15, 2018

Efficiency Maps for Electric Motors Made Easy

Simulating electric motors saves time, minimizes the number of needed prototypes and enables innovation as it is possible to virtually test a wide range of possible designs. Ansys can simulate electric motors in many ways: evaluate magnetic performance, predict thermal behavior, limit noise vibration effects, understand how to the machine interacts with the power electronics.

With the release of Ansys 19, we are excited to introduce a new capability within Ansys Maxwell specifically dedicated for electrical machines that are used in a wide range of operating conditions (speed, torque, current, etc). Think about an electric or hybrid car: the driver needs power for a variety of purposes (high torque when accelerating, high speed when cruising). Machine designers face big challenges to design and control such motors: how to optimize the performance when the motor is going to be used in a variety of conditions?

The optimal design for a low speed /high torque condition will probably not be the optimal design for a high speed /low torque condition. On top of that, for a given speed and torque, what is the best way to operate the machine and limit its power consumption? Designers not only need to have highly accurate simulations for one operating condition, they also need to know how the machine behaves across multiple operating conditions.

To that purpose, we are excited to introduce the Machine Toolkit. It is available as a free add-on to our core solver and will help machine designers produce efficiency maps, so that they can understand how the motor operates across the board. This is designed to mirror the way motor designers think.

User inputs:

- A machine setup (Permanent Magnet machine or Induction machine)

- The machine characteristics such as number of poles, max current, max speed, control type

- The level of accuracy the user wants to get (number of speed points, torque points

)

Panel to enter machine characteristics

Based on this information, the toolkit takes care of the rest of the flow. It will create a parametric analysis, sweeping all possible operating conditions. Typically, a few hundred transient simulations are necessary. The simulation is initiated by the toolkit. The simulation time can be greatly decreased using our Distributed Solved Technology: instead of solving each simulation one after another, we can solve simulations in parallel using the multiple cores of a desktop or a cluster. The speed up is spectacular: a typical speedup ratio is using 10 cores for this process will cut the simulation time by a factor of 9. It is also very scalable: using 100 cores will still provide a speed close to 90!

Once all the simulations are processed, the toolkit gathers all the necessary individual machine performances for each condition and starts a multi goal optimization. The toolkit determines the efficiency maps of the machine: how should the machine be used for each torque/speed condition, and how efficient is the machine under this condition. Once the optimization is finalized, we provide all the contour plots to the user (efficiency map, current map, loss map, ...) so that he can validate his design decisions.

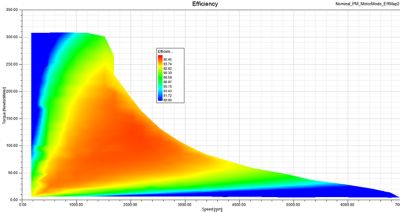

For instance, an internal permanent magnet efficiency map will look like this:

The X axis represents the speed (in rpm) and the Y axis represents the Torque (in Newton Meter). The map tells us that the motor is more efficient (on a 0-100 scale) when the speed is lower than 4,000rpm and the torque is lower than 250 NM.

An induction machine presents a different efficiency map topology:

The efficiency remains high even at high speed and high torque compared to an IPM machine. However, the induction machine is less efficient at low speed/ low torque. Providing a way to determine efficiency maps in an automated way is of great help for electric motor designers.

In addition, with the help of distributed solves, it only takes a few hours to run hundreds of transient simulations. A few years ago, creating a single efficiency map was taking days and required deep knowledge in scientific programming. Today, the full process is fully automated and is so fast that testing a large variety of machine topologies is possible within a day.