-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

ANSYS BLOG

July 24, 2019

Digital Threads Improve Designs, Development Cycles and Corporate Culture

Aerospace and defense (A&D) engineers need well-organized development cycles to bring products to market faster. This is why, the engineers at Avio Aero (a GE Aviation Business) created a digital thread to share all pertinent product development information — including simulation data, operating parameters, geometries and more.

Communicating all this information doesn’t just accelerate product development. Avio Aero engineers also noticed that it expedites environmental and safety compliance audits.

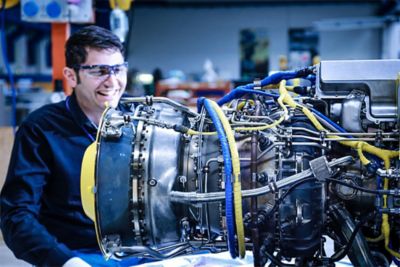

A lot of engineering teams are involved in the development of a jet engine. With a digital thread, these teams can better collaborate and communicate.

Additionally, when more engineers have access to more information, teams that were once siloed can work together to create innovative designs that meet fuel efficiency, costs and lightweighting goals.

For instance, teams working on simulations to lightweight a jet engine will have a better understanding of the jet’s operating conditions from the aerodynamic simulations. By making a digital prototype available to everyone, Avio Aero helps its structural and fluid dynamics teams communicate and collaborate.

Finally, digital threads are a first step toward developing digital twins. Once Avio Aero completes its digital twins, they will bring the data collected by products in the field into the development cycle. With this technology, Avio Aero’s real-world products will be able to better weather the environment in which they are placed.

How Digital Threads Change Corporate Design Culture

The implementation of a digital thread isn’t just about improving product design. It also improves the corporate design culture.

Most of the engineers in Avio Aero are well-versed in simulation, the digital thread helps these engineers share models and results.

This sharing has resulted in community-building, encouraging collaboration, cross pollination and new ways of thinking. It’s also enabled multiphysics analyses.

Thanks to the digital thread, this engineer has access to the knowledge of every other engineer working on the project.

Corporate morale has also improved as engineers are more likely to avoid:

- Handoffs

- Rework

- Data loss

- Ambiguity

To see how Avio Aero engineers plan to use digital threads to implement digital twins, read: Common Thread.

To learn how simulation can help other A&D projects, read: Accelerating Digital Transformation in Aerospace and Defense.