-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

ANSYS BLOG

December 21, 2023

Automakers Are Tackling Their Biggest Challenges Using Simulation

The automotive industry is one of the largest and most influential markets on the planet. It is currently experiencing more change than in the hundred years prior. The ever-changing landscape in the industry stems from rapid technological innovations, regulations associated with environmental and safety challenges, and customer and market expectations. Automotive original equipment manufacturers (OEMs) and suppliers are simultaneously grappling with the need to increase the electric vehicle (EV) adoption rate, add more capable assisted driving features, and innovate more personalized experiences for connected consumers. At the same time, they must continue to stay abreast of market challenges such as keeping vehicles affordable, understanding the quickly changing use cases of artificial intelligence and machine learning (AI/ML), and protecting against data breaches and cybersecurity.

For decades, automakers have used simulation to cut costs and time and improve quality in applications such as aerodynamics, durability, crashworthiness, and combustion. Today, the need to use simulation has grown exponentially to address all facets of vehicle design as the automobile becomes more complex. Let’s look at some of the use cases in the areas of electrified powertrains, assisted driving, and software-defined vehicles.

Electrified Powertrains

The urgency to transition vehicles to fully electric powertrains is top of mind in the industry. In some sense, electric powertrains are much easier to design because they have fewer components; gone are the hundreds of expensive, intricate parts such as radiators, pistons, fuel tanks, and spark plugs. But the industry still grapples with the biggest, most significant, and expensive component of the EV: the battery.

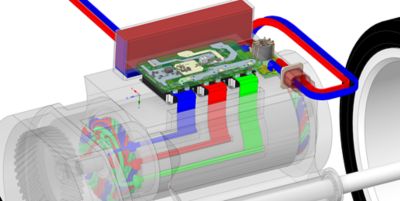

Simulation workflows are essential in developing the optimal size, package, and range of a battery. Effective simulations must detect and mitigate battery thermal run-aways during crashes, charging, and under extreme operating conditions. Physics-based reduced-order models (ROMs) of batteries are essential in the development of battery management software. Simulation is also critical in optimizing components with multiphysics design criteria — such as the structural, thermal, and electromagnetic requirements of the motor and power electronic modules. Optimizing these criteria simultaneously can only be done using simulation, which can explore thousands of design iterations at the same time it would have taken to design, build, and test a few iterations using the traditional method of physical prototyping.

Advancing Driver Assistance Systems and Autonomy

Some predicted we would be fully autonomous by now, but many developers have pulled back or delayed previously optimistic goals due to challenges limiting the acceptance and growth of self-driving vehicles. The public concerns underscore what has always been a primary concern of the automotive industry: ensuring the safety of drivers and passengers.

With the growth of compute power, AI/ML, and sensor technology, the industry can now offer a host of active safety features in addition to the traditional passive/crash protection. The gradual introduction and adoption of advanced driver assistance system (ADAS) features such as adaptive cruise control, automatic braking, and automated parking has driven demand for more driving assistance as customers appreciate their benefits and automakers realize the endless innovations possible to protect their customers.

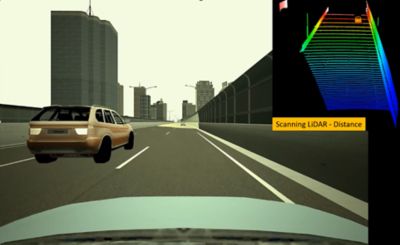

In the most complex systems it is no longer efficient, and sometimes impossible, to use the traditional design, prototype, and test development process. Simulation gives engineers the tools to navigate the complexities safely and efficiently. Rather than validating test cases over millions of physical miles, safe automated driving technologies can be virtually developed, tested, and validated in just a matter of days. Incredibly complex scenarios can only be identified by bringing safety analysis and simulation together to replicate real-world conditions and predict results much earlier in the development process.

Supporting Software-Defined Vehicles

As the amount of software in a vehicle grows to over 100 million lines of code, the industry has realized the necessity of transitioning to a software-defined vehicle (SDV) architecture. SDV is commonly used in the industry to refer to a vehicle that manages its operations and enables new features primarily or entirely through software. With SDVs, OEMs can add new features by changing only the software, without modifying the hardware; like the cell phone consumer product and experience. Software-driven features are developed as part of the original vehicle design but are also updated after the vehicle is sold through over-the-air (OTA) transmissions.

Methodologies such as model-based systems engineering (MBSE) are critical to managing the requirements for these features over the vehicle's life; not only for the requirements of the changing software, but also the original hardware requirements. Functional safety and cybersecurity analysis and assessment is also critical as part of the original design but also as the software continues to be improved. Likewise, simulation should be used to design the original vehicle hardware, but then also used to validate the new software over the life of the vehicle using the digital twin hardware models. Virtual validation is critical to assure safety and reliability before new software is dropped OTA to the customer’s vehicles.

Although EV powertrains, ADAS features, and SDVs are the latest trends in mobility, innovation continues throughout all aspects of motor vehicles, including lighter, more sustainable materials; “smarter” electromechanical components; and new lighting/optical technologies, among others. Simulation is critical to help ensure that each component is optimized to achieve the highest quality, lightest weight, lowest cost, and smartest technology.

In the latest issue of Ansys Advantage magazine, we tell the success stories of some of our customers who are using simulation and model-based methodologies to help address the increasing complexity of vehicle development. Only the most innovative and efficient will survive this transformation.