-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

ANSYS BLOG

May 12, 2022

Ansys Accelerates Development and Streamlines Design Process for Honda Motor Company

With record-low inventories at the dealership, shopping for a new vehicle is really challenging. It is an even tougher business environment for automobile manufacturers, who are struggling to overcome sluggish sales in the wake of the pandemic. Semiconductor chip shortages are significantly slowing vehicle production, as is the global transition to electric vehicles (EV) on the road to net zero. EV development is a high-stakes proposition in Western countries and others such as India and China, which are becoming increasingly competitive with government backing. Under these circumstances, Japanese automakers fear losing advantages in technologies, knowledge, and supply chains they have cultivated over time.

To curb the effects of the current climate, Automobile Operations at Honda Motor Company is looking to Ansys to streamline development and accelerate design drawing decisions to front-load the development process. By anticipating and addressing challenges early, the team hopes to avoid late-stage changes or loopbacks due to failed prototype testing, or those changes coming out of production that can significantly slow product development.

Timing is Everything

Yutaro Shimoda and Koya Sugawara have extensive experience using Ansys simulation software to help solve these challenges. Both are responsible for the development of front bumpers and door mirrors for Vehicle Development Division II, Finished Vehicle Development Management Department, Monozukuri Center at Automobile Operations for Honda Motor Company.

For Shimoda and team, the timing of any production decision is critical to general automobile development flow, from planning to development and production preparation. The later in the design phase the team is, the less freedom they have to change existing designs; however, it is common for performance evaluation accuracy to be lower at earlier phases. As a result, production drawings based on experience or knowledge are prioritized over those based on performance evaluation during physical prototype tests.

Taking this approach, performance evaluation results were applied to drawings just before the physical prototype, which resulted in a higher workload of rework for the team. The increase prompted computer-aided engineering (CAE) analysis using 3D-printed single parts or mockups for front loading, which came with its own set of challenges.

"We have a meeting with relevant departments every time new vehicle design is completed. We have to finish performance evaluation by the date set in that meeting," says Shimoda. "We of course perform CAE analysis and run tests using 3D-printed parts for performance evaluation, but these require some time if there are multiple designs. Especially at a phase where a prototype is not yet used, we have to use a 3D printer whenever possible so that performance would be evaluated in a real vehicle-like environment, but it is a heavy burden on us."

Design Selection and Verification with Ansys Discovery

Shimoda's team used Ansys Discovery to resolve these challenges. Using the simulation software, the team put aside the testing and performance evaluation of multiple designs in favor of design analysis and selection just before testing, reducing their test-related workload. This activity also enabled front-loading of conventional tasks mostly involved in physical prototype testing.

"There had always been a need for timely analysis and performance evaluation to facilitate development," said Shimoda. "With Ansys Discovery, we were able to check results in real time like a real test, in terms of time to prepare test analysis, time before checking results, easy parameter study, and variation in parts."

Analysis with the simulation software mimics the speed of testing in real time. To guarantee the accuracy of their results, the team can easily verify the correlation between analysis results with software and real events (test results).

Correlating Grille Wind Noise and Exterior Mirror Vibration

Discovery also helped Shimoda’s team identify wind noise generated by the front grille design, which produced a Kármán vortex street (vortex shedding, or a repeating pattern of swirling vortices related to fluid dynamics) when facing the wind. This phenomenon generates high-frequency wind noise that can be heard both inside and outside of the vehicle if no countermeasures are implemented.

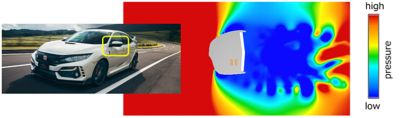

To analyze this event, the team made grilles with and without wind noise countermeasures in place using a 3D printer, then tested them. Analysis with Discovery helped the team visualize Kármán vortex streets and uncover a street for the grille without countermeasures. With newly identified countermeasures in place, the pressure and volume level of wind sound coming from the grille markedly decreased, confirming the correlation regarding bumper grille wind noise between Discovery analysis results and actual test results.

Sugawara used Discovery to verify door mirror vibration. If a door mirror vibrates while the vehicle is driving, the visibility of the mirror image will deteriorate. One of the vibration factors involved changes in traveling wind pressure, which affects the surface of a door mirror. To deliver high visibility required optimization of the shape of a door mirror to reduce pressure changes. The team compared real test values to Discovery analysis values regarding the distribution, fluctuation range, and fluctuation frequency of door mirror surface pressure. Resulting test values were nearly equal to the analysis values in all perspectives, supporting a positive correlation between simulation analysis and mirror vibration testing.

"We used to check the performance of multiple designs in tests using prototypes created with a 3D printer," said Sugawara. "Now that we know performance can be evaluated through analysis with Ansys Discovery, we can narrow down multiple designs into one first within the tool and then verify it in testing. This reduces the number of tests and the workload."

Leveraging High-Speed Data Analysis for Future Applications

Successfully solving their workload issue, Shimoda and Sugawara are now considering using the tool for other applications.

"By leveraging the advantages of high-speed analysis, we'd like to analyze data while testing and support mechanism analysis using the high-level visualization function of Ansys Discovery," said Sugawara. "We are thinking about performing real-time analysis in a meeting so that we can evaluate and decide specifications on the fly. We also hope to perform analysis on vehicle contact with water or snow and evaluate more events by improving the reproducibility of shapes, such as local gaps and steps."