Ansys Blog

September 10, 2019

Ansys 2019 R3 Improves the User Experience and Autonomous Vehicle Development

Autonomous vehicle development is dominating the engineering landscape. It’s to the point where the average consumer is willing to ride in an autonomous vehicle within their lifetime.

The engineers developing these autonomous cars, planes, boats and drones are tasked to make the operation of these vehicles functionally safe. Proving this level of safety will require testing autonomous vehicles for billions of miles. That is not feasible or cost effective.

However, engineers can use Ansys simulation to test every aspect of these autonomous vehicles in a virtual environment — reducing development times and getting to market faster. Ansys 2019 R3 offers engineers an end-to-end simulation solution that can perform:

- Closed-loop simulations

- Embedded software development

- Functional safety analysis

- Sensor simulations

- Human-machine interface (HMI) development

For instance, the release includes the launch of Ansys SCADE Vision, which enables engineers to evaluate the safety of autonomous vehicle perception systems.

Engineers developing autonomous systems will also benefit from the addition of:

- Ansys Speos Road Library for Sensors Simulation: a retro-reflecting materials database

- Creeping wave physics to Ansys HFSS SBR+ to predict radar cross sections of curved targets

For more Ansys 2019 R3 Product and Industry-Specific Highlights, Click Below:

- 3D Design: Reverse Engineering and Generative Design Updates

- Additive Manufacturing: Send Build Files Directly to AM Machines

- Electromagnetics: Access Expanded Ansys Cloud Capabilities

- Embedded Software: Ansys SCADE Vision Tests Embedded Perception Software

- Fluids: Run a Parametric Study Based on a Mosaic Mesh

- Materials: New Ansys Granta Selector Is Integrated into the Ansys Portfolio

- Multiphysics: Electrothermal Management with 3D-Transient Ansys Maxwell Simulations

- Optical: Ansys Speos Now Includes Head-Up Display Optical Design

- Platform: Ansys Minerva will Centralize an Engineering Team’s Knowledge

- Semiconductors: Power Efficiency and Reliability for Safety-Critical Automotive ICs

- Structures: Translate ECAD into FEA Models in Minutes

- Systems: New Digital Twin, Functional Safety and VR Capabilities

3D Design: Reverse Engineering and Generative Design Updates

Ansys 2019 R3 introduces Ansys Discovery Live’s interactive topology optimization tool for generative design.

Discovery Live also has new simulation capabilities, including:

- Mass flow outlets

- Transient studies with time varying inputs

These improvements will enable engineers to quickly and efficiently drill down to near-optimal designs.

A topology optimization created

using Ansys Discovery Live

Ansys 2019 R3 also includes an Ansys Discovery SpaceClaim tool for reverse engineering and generative design workflows. The tool can automatically create a surface reconstruction from faceted geometry and STL files — effectively making smooth, watertight computer-aided design (CAD) models from a triangle-based geometry.

Ansys Discovery AIM also has a series of updates in Ansys 2019 R3, including:

- Structural beam support

- Linear buckling support

- Physics-aware meshing improvements

- Mesh failure localization and visualization improvements

To learn of other improvements to Ansys 3D Design technologies, read more product and industry-specific highlights in Ansys 2019 R3.

Additive Manufacturing: Send Build Files Directly to AM Machines

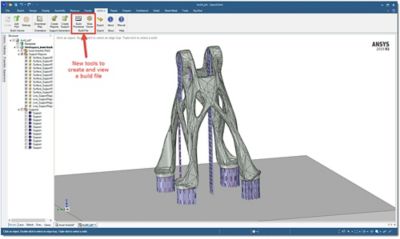

New to Ansys 2019 R3 is an Ansys Additive Prep build processor that can send files directly to additive manufacturing (AM) machines.

Additive Prep also has a new feature that can separate supports from the part without separating the part form the baseplate. Finally, Additive Prep can now account for multiple support types in one simulation.

Build file creation in

Ansys Additive Prep

Ansys Workbench Additive will also gain features in Ansys 2019 R3, including:

- The ability to toggle between STL supports, meshes and element densities

- An option to remove the AM process sequencer’s STL supports after cooldown

To learn of other improvements to Ansys additive manufacturing technologies, read more product and industry-specific highlights in Ansys 2019 R3.

Electromagnetics: Access Expanded Ansys Cloud Capabilities

Engineers who make use of Ansys Maxwell and Ansys Q3D Extractor will now be able to access the high-performance computing (HPC) abilities of the Ansys Cloud. This HPC option was previously available to users of Ansys Mechanical, Ansys Fluent, Ansys HFSS and Ansys SIwave.

In addition, the HFSS distributed memory solver benefits from enhanced algorithms that increase computing speeds and reduce memory footprints. This enhancement, in combination with the Ansys Cloud, delivers large benefits to users.

Ansys Mechanical, Ansys Fluent,

Ansys HFSS, Ansys SIwave,

Ansys Maxwell and Ansys Q3D

Extractor are all on the Ansys Cloud

For those working on developing autonomous vehicles, HFSS and HFSS SBR+ now include new abilities to post-process complex radar cross sections. Additionally, HFSS SBR+ has the new ability to use creeping wave physics to predict radar cross sections of large, curved objects.

Finally, the HFSS regions in Ansys SIwave hybrid solutions can be distributed across parallel compute resources. This feature will speed up the development of integrated circuit (IC) packages and printed circuit boards (PCB).

Embedded Software and VR: Ansys SCADE Vision Tests Embedded Perception Software

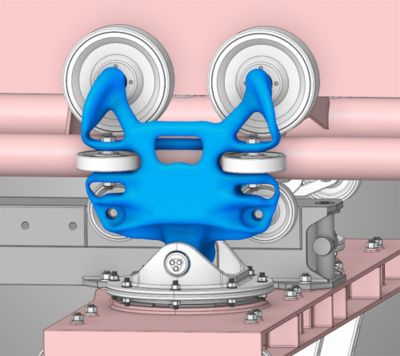

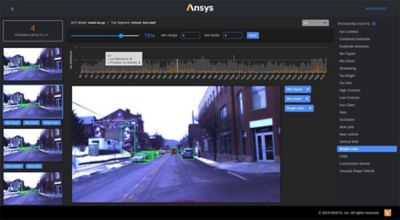

Ansys 2019 R3 debuts Ansys SCADE Vision, which enables safety analysts, neural network developers and engineers working on machine learning to test artificial intelligence (AI) based perception software with unlabeled data. SCADE Vision finds edge cases where the autonomous vehicle system might have difficulty identifying certain objects in a traffic scenario. Also, SCADE Vision ensures that the autonomous vehicle’s perception algorithm and AI are free from detection defects.

Ansys SCADE Vision helps engineers save time and

money testing embedded perception software.

Ansys SCADE also offers engineers a complete AUTOSAR software component. As a result, engineers can import large Simulink® models into SCADE — effectively reusing legacy models produced by system engineering teams.

Ansys VRXPERIENCE has new virtual reality (VR) capabilities that can connect human-machine interfaces (HMI) to software-in-the-loop.

In Ansys 2019 R3, the VRXPERIENCE also includes:

- Multi-bounce ray casting for ideal ground-truth sensors

- Flashing and rotating models for physics-based lidar

- Dynamic live previews of geometry movements

- Ansys SCADE Suite and SCADE Display integration to improve interactions with embedded software in VR

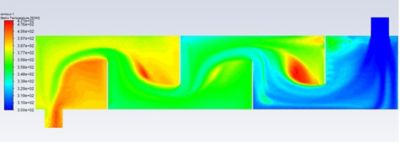

Fluids: Run a Parametric Study Based on a Mosaic Mesh

Ansys 2019 R3 comes with a few Ansys Fluent user experience boosts. One such improvement includes the ability to use Mosaic meshing technology when running parametric studies in Ansys Workbench. Additionally, engineers can apply fault-tolerant meshes to nonconformal interfaces while performing a conjugate heat transfer simulation.

Ansys Fluent can now post-process and evaluate

complex reduced-order models (ROMs).

Another user experience boost is that engineers can use the Fluent expression language with parameters, reports and monitors.

Other improvements to Ansys computational fluid dynamic (CFD) technologies include:

- Creating organic, optimal shapes using the Fluent adjoint solver automated workflow

- Evaluating complex reduced-order models (ROMs) using Fluent

- Assessing conjugate heat transfer by combining Ansys Forte with Fluent or Ansys Mechanical

To learn of other improvements to Ansys CFD technologies, read more product and industry-specific highlights in Ansys 2019 R3.

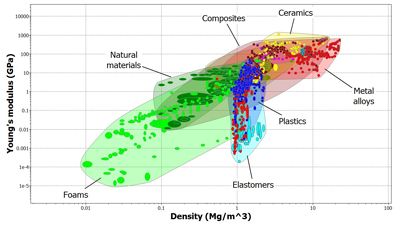

Materials: New Ansys Granta Selector Is Integrated into the Ansys Portfolio

Ansys 2019 R3 also launches Ansys Granta Selector. This new Selector is based on 25 years of experience and materials selection technology that was included in the earlier version of CES Selector.

What sets the new Selector apart is its updated interface and the ability to integrate with the Ansys portfolio.

Ansys Electronics Desktop can

now access Ansys Granta

Materials Data for Simulation.

Selector includes a comprehensive materials data library and tools to apply this data in materials selection and analysis.

This new Selector strengthens the metals data offering by making it easier to compare, study equivalencies and select materials across global metals standards.

Electromagnetic engineers will also benefit from access to Ansys Granta Materials Data for Simulation in the Ansys Electronic Desktop. These engineers join Ansys Mechanical users in having access to many hundreds of records of electromagnetic, mechanical and thermal properties across various material classes.

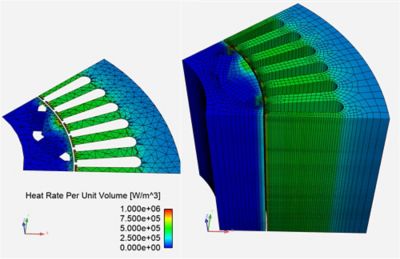

Multiphysics: Electrothermal Management with 3D-Transient Ansys Maxwell Simulations

Engineers who use Ansys System Coupling to perform Ansys Multiphysics simulations that address electrothermal management problems can now include cases with 3D-transient Ansys Maxwell analysis. This extends the Maxwell coupling capabilities that previously included 3D eddy current and 2D transient cosimulations.

These new Maxwell multiphysics coupling capabilities will be useful to engineers working on the electrothermal management of busbars and motors.

Electrothermal co-simulation of an

electric motor using Ansys System

Coupling, Ansys Maxwell (left)

and Ansys Fluent (right)

The performance and accuracy of Ansys Multiphysics is also improved. Industrial benchmark tests show that system coupling performs 15% faster, and leads to faster cosimulations, than previous releases.

Engineers will also have access to a best-practices guide within the Ansys System Coupling documentation that outlines how to simulate two-way, fluid–structure interactions with deformations.

Optical: Ansys Speos Now Includes Head-Up Display Optical Design

In Ansys 2019 R3, Ansys Speos gains a feature that is dedicated to the generation of optimal head-up displays (HUD). The feature improves the legibility and clarity of the images produced by the HUD by optimizing its layout and shapes. This feature works directly in a CAD environment.

Ansys Speos can generate an optimal

HUD to improve image clarity.

The latest release of Ansys Speos also includes support for meshed geometry. This improves Speos’s integration into multiphysics workflows and the Ansys platform.

Additionally, Speos now includes an improved interface and user experience. For instance, Speos Live Preview includes the ability to switch between true and false colors with one click. Users can also quickly adjust the scale adaption and sensor type.

Speos has added sensor capabilities with the release of the Speos Road Library for Sensor Simulation. This library includes retro-reflecting materials (like asphalt, signs, paint and vegetation) that are detectable by any sensor.

The Ansys 2019 R3 release of Speos also includes the ability to:

- Use ambient and thermal models to improve optical simulations with the sky and sun

- Simulate rotating lidar

Platform: Ansys Minerva will Centralize an Engineering Team’s Knowledge

Ansys 2019 R3 also launches Ansys Minerva, a centralized simulation knowledge management application. Minerva is powered by Aras’ resilient platform. It offers engineering teams a single location to store:

- Data

- Project plans

- Analytics

The information on Minerva can be made accessible to team members across the world and industry silos. Minerva’s ability to centralize a team’s engineering knowledge into one location will help to reduce reworks and get products to market faster — on lower budgets.

The release also includes a method to evaluate operating systems with distributed computer services (DCS). This family of applications enables engineers to optimize the distribution, management and solve times of various compute resources.

Distributed computer services (DCS) optimizes compute resources.

Another platform improvement is that Ansys Cloud is now available to Ansys Maxwell and Ansys Q3D Extractor users. Ansys Cloud offers easy access to on-demand HPC resources, on Microsoft® Azure™, that are optimized for the Ansys portfolio. It has previously been made available to:

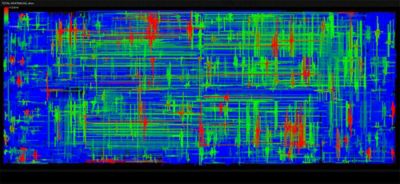

Semiconductors: Power Efficiency and Reliability for Safety-Critical Automotive ICs

The Ansys semiconductor portfolio has achieved ISO 26262 “Tool Confidence Level 1” (TCL1) certification for power efficiency, power integrity and reliability solutions. As a result, designers of automotive ICs can use this portfolio to meet the rigorous safety and reliability requirements to develop advanced driver assistance systems (ADAS) and autonomous applications.

A temperature map from an Ansys RadHawk-SC thermal simulation

Specifically, automotive IC designers can use Ansys PowerArtist, Ansys Totem and the Ansys RedHawk family of solutions for ISO 26262 safety-critical development projects.

Multiphysics challenges, such as power, thermal and reliability, are important to the design of advanced FinFET process nodes and 2.5/3D-IC packaging technologies. The use of these technologies in ADAS and autonomous systems is increasing. Ansys semiconductor solutions comprehensively address these multiphysics challenges across the chip-package-system. Ansys and the Taiwan Semiconductor Manufacturing Company (TSMC) have collaborated on this front to release the Automotive Reliability Solution Guide 2.0 for 7nm FinFET process technology.

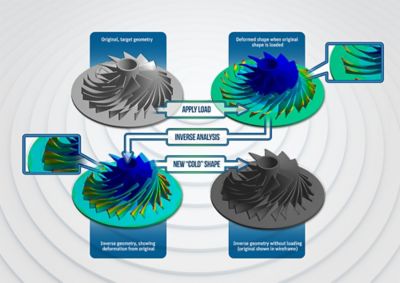

Structures: Translate ECAD into FEA Models in Minutes

In Ansys 2019 R3, the addition of Ansys Sherlock brings engineers numerous electronic hardware analysis capabilities. For instance, within minutes, engineers can translate electronic-CAD (ECAD) models into finite element analysis (FEA) geometries. These models can then be used to predict an electronic component, board or system’s time to failure.

An inverse analysis example using turbomachinery

Ansys Mechanical also has a new inverse solver. The solver can be used to determine the shape of a part before it experiences extreme loads and deformations.

Ansys 2019 R3 also includes the ability to use:

- A new coupled field analysis system in Ansys Mechanical to couple thermal and structural felid analysis for both static and transient simulations

- Ansys Motion within Ansys Mechanical to solve complex flexible and rigid multibody dynamics (MBD) simulations

- 120 new materials from the Ansys Granta Materials Data for Simulation database, which now includes electromagnetic properties.

Systems: New Digital Twin and Functional Safety Capabilities

Ansys Twin Builder has received electrification-specific enhancements that improve its ability to simulate battery management systems and deploy other electronic digital twins. This will improve an engineer’s ability to validate and deploy simulation-based digital twins for the predictive maintenance of electronic components and systems.

Other improvements to Twin Builder include:

- Modelica enhancements

- New ROM capabilities

- Electronics control model (ECM) toolkit upgrades

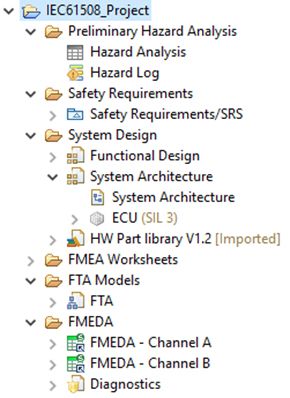

Ansys medini analyze can now be used to study industrial equipment that must meet the IEC 61508 standard. This expands medini analyze’s functional safety analysis beyond automotive and aerospace applications.

The process tree of

Ansys medini analyze

Engineers can also use medini analyze to ensure consistent safety integrity level (SIL) management for:

- Process hazard analysis (PHA)

- Systems requirements

- System design

Engineers can then use medini analyze to study failure modes, effects diagnostic analysis (FMEDA) with safe failure fraction (SFF) and diagnostic coverage (DC) computations.

To learn of other improvements to Ansys systems engineering technologies, read more product and industry-specific highlights in Ansys 2019 R3.