-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

Ansys for Hybrid Digital Twins

Combining physics and data modeling to enable real-time monitoring, predictive maintenance, and performance optimization.

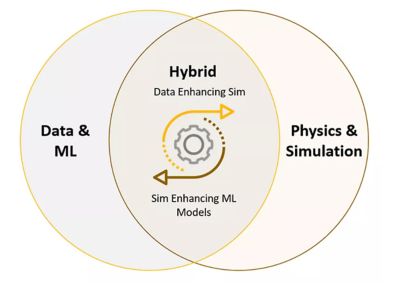

The Best of Machine Learning and Physics

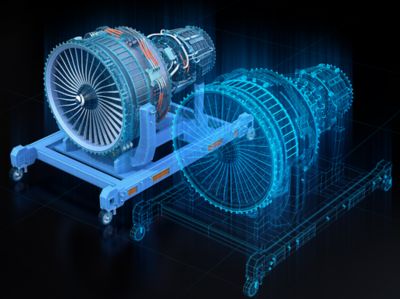

A hybrid digital twin is a virtual representation of a connected physical asset made possible by combining advanced simulation and analytics.

Used across various industries, from virtual sensoring to learning unmodeled physics, hybrid digital twins help companies solve many challenges and enable real-time monitoring, predictive maintenance, and performance optimization of systems and processes.

-

Real-time monitoring

-

Predictive maintenance

-

Systems performance optimization of systems

-

Systems performance of processes

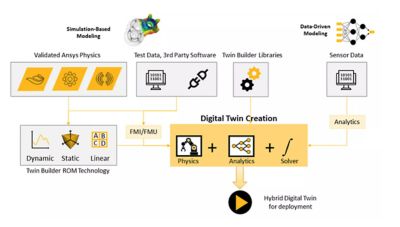

Ansys Introduces Hybrid Digital Twin

Reusing engineering design in operations

A hybrid digital twin originates during design, utilizing design models to capture intent and specs. Reduced Order Modeling (ROM) technology enables complex CFD and FEA models for real-time applications, broadening possibilities for complex systems.

Look-ahead performance

Monitoring assets in the field is valuable, but predicting future behavior is ultimately where digital twins provide maximum value. Hybrid digital twins are critical for look-ahead performance prediction in unbounded conditions.

Designing for data and learning from data

A hybrid digital twin embodies a synergy between data and simulation where the simulation provides more data for data models. In contrast, sensor data from the field teaches the model about operational performance.

Closing the design loop

By continuously learning from field data, an updatable twin shows which components and parameters change over time. This information can predict the remaining useful life of a piece of equipment. Tracking this is valuable for predictive maintenance and design teams to see whether equipment performs as expected.

Using Ansys technology, Bosch is creating digital models that take advantage of the capabilities of artificial intelligence (AI) and machine learning. See how the digital twins are driving the latest innovations in electric vehicle design.

Featured Resources

BLOGS

WEBINAR ON DEMAND

VIDEOS

The Twin Talks: Introduction to Hybrid Digital Twins

The Twin Talks: Introduction to Hybrid Digital Twins

In this 3rd episode of The Twin Talks, we'll discuss the hybrid digital twin concept and how this technology represents a transformative approach in the digital twin landscape, distinguishing themselves from traditional digital twins by seamlessly integrating physics-based simulation and real-time data analytics. We'll also highlight the key benefits of adopting hybrid digital twins and how they offer the ability to optimize operations, enhance decision-making, and improve overall performance.

Let’s Get Started

If you're facing engineering challenges, our team is here to assist. With a wealth of experience and a commitment to innovation, we invite you to reach out to us. Let's collaborate to turn your engineering obstacles into opportunities for growth and success. Contact us today to start the conversation.