-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

ANSYS ADVANTAGE MAGAZINE

DATE: 2020

Powered by Partnership

By Ansys Advantage Staff

Since 1982, the groundbreaking compressor designs launched by Embraco, the Brazilian hermetic compressors for refrigeration reference brand, have been fueled by a close relationship with its academic partner, Universidade Federal de Santa Catarina (UFSC). Working collaboratively via a shared engineering simulation platform, they have introduced innovations that have changed the nature of compressor design, including variable running velocities that conserve energy.

Founded in 1971 in Joinville, Brazil, Embraco was created with a straightforward goal: to provide a domestic source of compressors for the Brazilian refrigeration market. Today, as part of Nidec Global Appliance, a division of Nidec Group, the company is a global leader in compressor design, supplying next-generation compressors to OEMs in the household, food service and grocery refrigeration segments.

According to Rinaldo Puff, fellow researcher at Nidec Global Appliance, the foundation for the company’s current success began in 1982 when the engineering team made two critical decisions. First, the company became one of the earliest adopters of engineering simulation in the worldwide refrigeration industry. Second, they formed a partnership with Universidade Federal de Santa Catarina (UFSC), a local university with an outstanding reputation for research and development.

Professor Alvaro Toubes Prata, Universidade Federal de Santa Catarina (UFSC) (left). Rinaldo Puff, fellow researcher, Nidec Global Appliance (right)

Over the 38 years since, Nidec Global Appliance and UFSC have collaborated on engineering innovations that have revolutionized the refrigeration industry — including a linear compressor design that offers significant maintenance benefits over traditional reciprocating designs. More recently, the team introduced a variable-velocity compressor built to address customer concerns about energy efficiency by continuously changing its cycling speed.

The global compressor market is no stranger to disruption. “Every few years, customers demand a better design with greater cooling capacity, lighter weight, lower noise levels and reduced energy needs,” explains Puff. “We are constantly striving to be first-to-market with the next big innovation, whether that means new materials, new electrical efficiencies or mechanical improvements.”

Bridging Fundamental And Applied Science

Puff, who holds 33 patents for compressor innovations, notes that the Nidec Global Appliance–UFSC team’s engineering projects have been commercially successful because the team focuses on answering demonstrated market needs with innovation.

“The variable-velocity compressor is a great example of a customer-driven improvement,” he says. “Refrigerator manufacturers were looking for a way to decrease overall energy consumption to satisfy consumers and also meet stricter regulatory standards. The work with UFSC increased internal knowledge, helping in the creation of several product families, including the variable-capacity compressor designed to work at changing speeds while maintaining adequate cooling output. This pioneering design has resulted in significant energy savings, without sacrificing cooling performance.”

Professor Alvaro Toubes Prata had just earned his doctorate in mechanical engineering and joined the UFSC faculty when the company approached the university to explore a partnership in 1982. Today, he heads the team of faculty and student researchers at UFSC who support Nidec Global Appliance R&D initiatives.

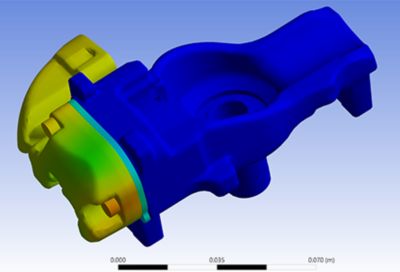

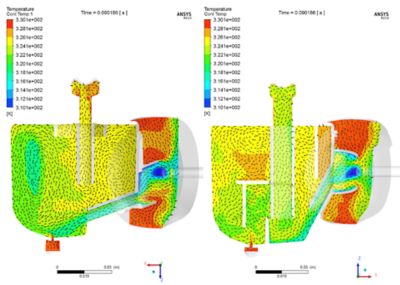

Nidec Global Appliance has multiple engineering teams working together in real time on Ansys multiphysics simulations to speed the development process

“What makes this collaboration work is that it brings UFSC’s fundamental engineering knowledge — our expertise in mechanical engineering, fluid dynamics and other areas — together with practical applications for that knowledge,” says Prata. “When Nidec Global Appliance first introduced this idea, UFSC had absolutely no experience in compressor design. But we loved the challenge of applying our theoretical understanding to a real-world problem.”

According to Prata, the partners’ projects over the past 38 years have been focused on three major objectives:

- Incremental improvements at the component level, such as changing the geometry of one component slightly to achieve a desired performance result

- Design updates to improve the product as a whole, like re-engineering the valve design based on new operating parameters for the entire product

- A ground-up re-imagining and redesign of the entire product, as when they fundamentally changed the design of a compressor from a reciprocating design to a rotary design using a rolling piston

“Over 38 years, we have completed a surprising number of R&D projects with Nidec Global Appliance that have changed the compressor category,” says Prata. “Not only is it gratifying to perfect a new design and impact an entire product category, but that work increases UFSC’s broader scientific knowledge — and can ultimately impact society as a whole.”

Nidec Global Appliance says its FMFT is the first commercial refrigeration bivolt compressor and one of the world’s most efficient in its capacity range. It reduces energy consumption by up to 30%.

How do the partners choose where to focus their efforts? Puff notes that Nidec Global Appliance and UFSC meet regularly to discuss emerging market needs and technology trends. “We might get feedback from a customer, or someone from UFSC might attend an engineering conference — and that provides the initial inspiration. Often, we end up investing heavily in an idea, but we also explore and discard some potential projects,” Puff explains.

Collaboration Begins At Home

In addition to its groundbreaking partnership with Universidade Federal de Santa Catarina, Nidec Global Appliance has won industry awards that recognize the innovative nature of its internal R&D organizational structure, which is also highly collaborative in nature.

“Nidec Global Appliance is unique in the way we bring multiple functions together in real time to work on development projects,” says Rinaldo Puff, fellow researcher. “Unlike most engineering teams, which design products incrementally and sequentially, we have multiple engineering teams — in structural analysis, thermodynamics, fluids and other areas — working together in real time, on multiple aspects of a new compressor design. This not only speeds the development process, but it ensures we arrive at the best possible solution, in which all performance trade-offs are optimized.”

Puff points out that all of Nidec Global Appliance’s engineering disciplines are brought together for the development of all new products, so that every design aspect can be optimized — and the impact of every physical force can be completely understood from the earliest design stages.

“Specialists with functional knowledge share information with each other on a daily basis, working with a common toolset that includes simulation software,” says Puff. “We believe strongly in the Design for Six Sigma approach, in which advanced technologies are leveraged to anticipate trade-offs — and ensure that the countereffects of decisions in one area do not negatively impact the overall design. Design for Six Sigma, and our use of Ansys software for multiphysics analysis and virtual prototyping, ensures that the product design is verified and optimized well before we invest in a physical prototype build.”

Puff says Nidec Global Appliance’s cross-functional, interdisciplinary approach is unique in the global refrigeration industry — and a key reason the company has been successful.

“Innovation and collaboration are in our culture and DNA,” Puff concludes. “That commitment is transmitted to the outside world in everything we do. In my opinion, that is why we have been recognized by the industry, and are respected by both our customers and our competitors.”

Nidec Global Appliance and UFSC collaborate more efficiently on the Ansys platform.

Engineering Simulation: A Platform For Collaboration

Both Puff and Prata agree that the team’s use of Ansys simulation solutions as a common platform has helped support collaboration, as well as accelerate the research and development process.

“Ansys simulations are critical tools because, like our team, they bridge fundamental and applied science. Whether we are testing a theory about fluid flows in general or verifying the effects of a certain flow velocity on a specific valve geometry, Ansys software is one of the best available tools. It also supports the kinds of multiphysics, system-level studies we need to replicate all the complexities of compressor operation,” Prata points out. Both partners use a full range of simulation software, including structural, computational fluid dynamics and electromagnetics solutions.

“Handing off projects with UFSC is much easier because we are standardizing our engineering efforts via Ansys solutions,” Puff concurs. “We are speaking a common language and sharing the same perspective on the inner workings of the compressor. There is no need to explain various tests and findings, because we are all fluent in engineering simulation via Ansys.”

Just as UFSC’s master’s and doctoral students are benefiting from the opportunity to work on real applied engineering challenges, they also are being trained daily in the industry’s leading simulation tools.

“The Nidec partnership is preparing our students to work in the real world after graduation by giving them the skills they need to succeed, including engineering simulation,” Prata emphasizes. “An unexpected result is that many of our graduates have gone on to work for Nidec Global Appliance’s in-house product development team — which is a benefit for both these students and the company. This knowledge pipeline means that the company’s technical leadership just keeps growing and growing.”

The Right Partner, The Right Tools

As a result of their long partnership, not only is Nidec Global Appliance a market reference in compressors with Embraco’s products, but UFSC has become the center of engineering research on refrigeration in Brazil. For both partners, this is only the beginning.

“We cannot rest on the results to date,” stresses Puff. “We must continually seek out new technologies and best practices that take our compressors’ performance to the next level.” As just one example, Puff notes that Nidec Global Appliance and UFSC are exploring the concept of the digital twin — installing Internet of Things (IoT) sensors on a working compressor to create a real-time, virtual product model that engineers can study and learn from.

What advice would Puff offer to other companies seeking to establish product leadership in a competitive industry? “Obviously we believe in identifying and capitalizing on the newest thinking via a partnership with the world’s leading engineering experts — meaning our collaborators at UFSC,” he says. “But, equally important, both partners must identify and capitalize on the best-available engineering technologies. You never know what you can accomplish by forming an expert team and supporting that team with best-in-class technologies and practices.”

Let’s Get Started

If you're facing engineering challenges, our team is here to assist. With a wealth of experience and a commitment to innovation, we invite you to reach out to us. Let's collaborate to turn your engineering obstacles into opportunities for growth and success. Contact us today to start the conversation.

?)

?)