Discover how coupling Ansys structural simulation software with the Ansys Digital Twin platform is helping manufacturers solve extremely large, complex safety challenges faster.

A preliminary report by Jeju Air recently confirmed that a bird strike — when an airborne animal collides with an aircraft — caused the fatal crash of one of South Korea’s commercial airplanes Dec. 29, 2024. This determination was made after DNA evidence of native waterfowl was recovered from both engines of the plane.

Bird strikes happen 47 times a day on average, according to the Federal Aviation Administration, but outcomes like the Jeju Air incident are rare. Both the aviation industry and the U.S. Fish and Wildlife Service have come up with mitigation strategies to manage these incidents, including bird hazing and removal, habitat management, and flight schedule changes to avoid high levels of bird activity.

Still, data from the Fish and Wildlife Service suggests that wildlife strikes to aircraft cause an estimated $900 million in damage to U.S. civil and military aircraft every year.

Thankfully, when a bird strike seems unavoidable, there’s simulation. Simulation’s power puts impact scenarios like these to the test through virtual modeling, resulting in safer outcomes in automotive, aerospace and defense, civil engineering, and healthcare, to name a few. And it’s one more way that the aviation industry is bird-proofing its aircraft designs.

Let's take a look at how Ansys LS-DYNA nonlinear dynamics structural simulation software, when coupled with the Ansys Twin Builder simulation-based digital twin platform, delivers a simple approach to tackling complex safety engineering challenges like these and others that span industries.

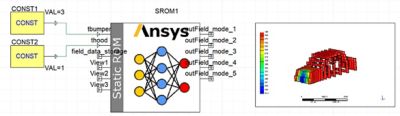

The image illustrates the consumption of a parametric field history reduced-order model (SROM) in the Ansys Twin Builder simulation-based digital twin platform, where input constants feed into the ROM and the outputs drive a transient structural visualization. This setup enables efficient real-time simulation and analysis.

LS-DYNA Software Finds a Model Surrogate

LS-DYNA software provides the foundation for this coupled approach to solving large-scale safety challenges. Among Ansys’ mechanical solutions, LS-DYNA software clearly stands out in addressing these types of challenges, as it is a finite element analysis (FEA) program consisting of not one but multiple multiphysics solvers.

“Rather than other solvers that are typically strong in one physics application or another, LS-DYNA software draws its capabilities from multiple physics,” says Anirban Basudhar, principal R&D engineer at Ansys. “It enables strong couplings — even monolithic coupling — where these various physics can be solved together, leading to greater accuracy in terms of analytical results.”

Consequently, LS-DYNA software is well suited to the analysis of short-term, transient, highly nonlinear dynamic events. These include vehicle crash testing, drop testing, and defense applications in which impacts from events (like explosions) might be considered. However, simulating these events often requires tremendous computational resources.

This is where the reduced-order modeling (ROM) capability in Twin Builder software comes in. Its use in LS-DYNA software as a surrogate model application within a finite element model enables the replacement of more complex structures, saving simulation time without losing accuracy.

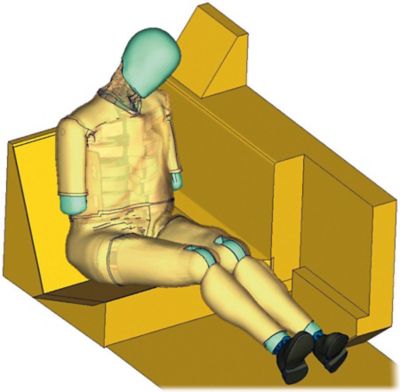

Ansys LS-DYNA nonlinear dynamics structural simulation software dummy model in a side-impact scenario

Breakin’ It Down With Twin Builder ROM Technology

To compute simulation results, LS-DYNA software works by doing the discretization of physical models. To obtain accurate results, very often this discretization needs to be quite fine, leading to high computational costs.

The biggest benefit of these ROMs is that they are simplifications of high-fidelity, complex models. ROMs capture the behavior of these source models so engineers can quickly study a system’s dominant effects using minimal computational resources. By enabling the reuse of pre-existing data for standard components, a significant reduction in LS-DYNA simulation time is realized.

“The integration of LS-DYNA software with Twin Builder software enables the replacement of some of the discrete components with ROMs, which act as computationally inexpensive surrogates of those components,” says Basudhar.

In this coupling scenario, ROMs are generated offline in advance using Twin Builder software based on prior LS-DYNA simulation results. After that, only a few components are modeled using the finite element method while the rest are represented by simplified ROM evaluations using the Twin Builder library. The main benefit of the eventual LS-DYNA/Twin Builder coupling is faster ROM analysis without a loss in results accuracy.

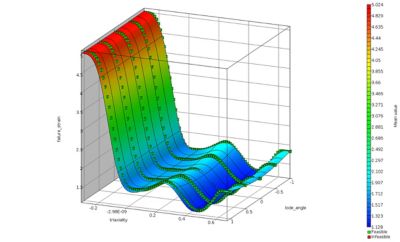

Failure surface where the plastic failure strain is defined as a function of triaxiality and the lode parameter

Structural ROM Integration and the Magic of Ansys optiSLang Pro Software

Generally, this simulation technique is done for standard components that do not change much between design periods or phases. This enables efficient, fast analysis in LS-DYNA software in the future.

Additionally, this integration can enhance crash simulations or structural analysis in automotive and aerospace applications through the Ansys optiSLang Pro process integration and design optimization software feature within LS-DYNA software for design optimization and probability analysis. The feature is used to schedule LS-DYNA simulations based on a selection of distinctive designs (called experimental design sets), typically on a remote cluster.

Post-analysis, optiSLang Pro software reads the LS-DYNA database for selected data, which it then assembles and exports in a suitable format for input into Twin Builder software. Twin Builder software is then used to produce a ROM of the LS-DYNA model, and the ROM becomes a surrogate of the LS-DYNA model. This surrogate can then be used as a surrogate solver in an LS-OPT workflow to conduct fast design optimization or reliability/robustness studies.

In other instances, the LS-OPT feature can produce a ROM component that can interface and couple with an LS-DYNA model.

“This work is typically done for standard components, which do not change much between design periods or phases, so that they can be reused for efficient and fast analysis with LS-DYNA software during a process known as ROM optimization,” says Basudhar.

The Ultimate Mash-up for Understanding Automotive Crashworthiness

This LS-DYNA/Twin Builder mash-up is significantly impacting automotive safety, which is a big priority for original equipment manufacturers (OEMs). Vehicle safety directly affects their profitability, and brands must inspire trust through crashworthiness. Incidents due to design failures can result in costly recalls and open up the potential for occupant injuries and fatalities, eroding public trust.

To this end, structural ROM integration facilitated by the LS-OPT feature benefits the automotive industry in two ways:

- It accelerates the design process. Once a ROM is generated, its evaluation is several orders faster compared with corresponding LS-DYNA simulations, which speeds up design exploration. Significant gains can be made using the LS-OPT feature, as it has an interface for running Twin Builder software as a solver in an automated design process. This results in a flexible process integration platform in which accelerated design optimization or statistical analysis can be performed either using only the ROMs or in combination with more LS-DYNA simulations for further enrichment.

- It accelerates LS-DYNA simulations. Force and torque versus displacement and rotation ROMs for standard components can be pretrained and used in hybrid-system-level LS-DYNA simulations, in which some components are finite element components while the rest are represented by the interface ROMs. This enables significant simulation acceleration and facilitates system analyses that would otherwise be prohibitively expensive computationally.

As previously mentioned, this approach is suited to applications where design changes normally aren’t expected.

For instance, the Ansys team is working on a recliner mechanism for a standard component that’s fitted to all kinds of vehicles and all types of seats. It is incredibly detailed — which is typical for these types of parts, which can have between 2 million and 10 million elements. It’s an expensive component for LS-DYNA analysis and a perfect ROM use case.

“A comprehensive seat simulation in LS-DYNA software may consider elements that comprise the entire seat, the dummy seated on it, and various other elements of the vehicle,” says Nielen Stander, senior principal R&D engineer. “If there are standard components, and these vehicles typically have a lot of standard components provided by suppliers, they can be converted into (a) ROM, then coupled into the LS-DYNA analysis to save time.”

There is a trade-off with ROMs in this scenario, however, in the trading of accuracy for speed. It’s a penalty of up to 10% to 15%, but these losses are insignificant when considered in the context of an entire development arc. For simulations done in the preliminary design phase, accuracy is not necessarily as important as it is during the final design phase, when the entire seat system is considered.

Specifically, it’s possible for a user to create a ROM and do a lot of preliminary work to investigate how design changes affect responses and other relevant criteria when refining a vehicle seat design. For example, consider a sled test scenario in which you have a seat and a dummy, and you’re investigating this system.

“In the case of this sled test, there are multiple physics involved, with some being more critical than others and some more expensive than others,” says Stander. “A lot of times, what happens is, users are hesitant to include all their criteria due to high computational times. Including a ROM alternative with that validation may not be 100% accurate, but it has some accuracy, which can be pretty good in some cases. And this allows them to include those additional load cases or disciplines into the optimization process without that deterrent cost penalty.”

These types of scenarios reiterate the inherent value of an LS-DYNA/Twin Builder ROM-based approach to analysis. The ability to consider new aspects of entire systems, like the seat system, gives way to faster discoveries at the front end of a development cycle. As a result, customers save valuable time that can be relegated to the end of a cycle, when accuracy is critical.

Discover how Ansys solutions like Twin Builder ROMs streamline LS-DYNA crash simulations, optimize workflows, and accelerate robust system development in this on-demand webinar: “Accelerating Ansys LS-DYNA Simulations With Reduced-order Modeling and Hybrid Analytics.”

Just for you. We have some additional resources you may enjoy.

“Rather than other solvers that are typically strong in one physics application or another, LS-DYNA software draws its capabilities from multiple physics. It enables strong couplings — even monolithic coupling — where these various physics can be solved together, leading to greater accuracy in terms of analytical results.”

— Anirban Basudhar, Principal R&D Engineer, Ansys