-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

See how the carmaker is leveraging software to develop its rapidly evolving automotive interiors.

Aspirational automaker the BMW Group prides itself on creating individual, unmistakable driving experiences, from the high-performance luxury of a BMW and the A-lister opulence of a Rolls-Royce to the free-spirited MINI. Apart from premium performance, a focus on interior refinement has inspired some truly unique features. These include Swarovski crystal shift knobs, starry sky projections in the headliner, and digitally projected art displays on the dash.

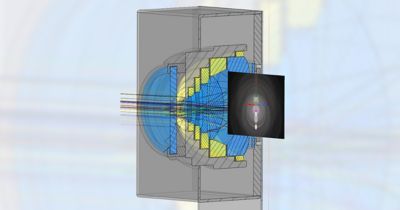

Introducing features like these into an already busy interior environment can be challenging. The light from backlit buttons, infotainment and instrumentation displays, plus the glare from the sun or oncoming headlamps at night are all competing to the point of distraction. Leveraging Ansys simulation software running on an NVIDIA GPU-accelerated computing platform enables the BMW Group to address unwanted reflections and glare, thereby ensuring a comfortable driving environment.

i8 interior lighting: day and night studies

Reflecting on Dash Designs With Simulation

Kenneth Weselake, virtual validation project leader at the BMW Group, uses Ansys Speos computer-aided design (CAD) integrated optical and lighting simulation software early on to do light studies to optimize optical interior elements for the BMW, Rolls-Royce, and MINI Cooper brands.

“We are cleverly using light as an information carrier, creating entertaining animations, implementing hidden projectors allowing the digital world of the displays to overflow out onto the dash, thus connecting the digital and physical worlds,” says Weselake. “We are merging light, materials, and controls. We have light streaming through materials and multiple displays reflecting in the front windshield, which we have branded BMW Panoramic Vision.”

All of these elements are guided by the light properties of a range of material and color choices. And all must be ranked and evaluated for various elements of the dash to determine what can be possible with safety in mind.

A big challenge is how to allow lighter colored interiors without disturbing the driver. A careful consideration of branding, plus all the materials involved in creating dash components were needed, as well as the use of textures to reduce reflections. Weselake successfully used Speos software to experiment with different color gradients, dash geometries, and materials to minimize unwanted reflections and glare.

“I've measured over a thousand different materials,” says Weselake. “This is necessary to perform comparison studies. I'm using Speos software to gauge the color intensities. Referring to my cockpit setup, I can update my dash model in Speos software again with all the different materials to see the influence the geometry, as well as the materials, has on the results. Early on in the design process, I’m still able to have an influence on the geometry. Later on in the design process, it’s mainly materials."

Top: Rolls-Royce Phantom dashboard comparison of lighting scenarios and anti-reflex coatings for the glass. Bottom: Rolls-Royce door simulation of the lighting effects and reflections.

Analyzing Optical Designs 300 Times Faster With NVIDIA Accelerated GPU Computing

At the BMW Group, Weselake has a unique opportunity to develop a wide range of interior lighting concepts, from the playful and fun of the MINI to the more refined of BMW to the ultimate luxury of Rolls-Royce. While they all vary stylistically, these simulations tend to be quite large requiring long run times. Previously, using CPU computing, Weselake had to do test runs over several hours. At the conclusion of these test runs, the actual simulation would take up to a week. If there were any problems, the entire test and actual simulation cycle would most likely need to be repeated.

Leveraging Speos software and NVIDIA RTX 6000 Ada Generation GPUs enabled Weselake to run optical simulations 300 times faster. Breaking this down further, the setup gave a significant boost to Speos software’s performance, reducing individual test runs from several hours to under 10 minutes.

“The ability to reduce that time for the simulations from up to a week to just a few hours or even a few minutes has been really beneficial to my work,” says Weselake. ”Every time I ran something that's fairly large, I was looking at a several day, up to a week of simulation time. Now I can use that extra time to direct my energy to other tasks.”

So, how is this speedup even possible? NVIDIA’s accelerated computing platform combines massive 48GB of memory and incredible performance. Leveraging it with Speos software enables Weselake to access the power needed to perform complex optical simulations, increasing the number of design iterations to solve challenges faster. It also made quick, impromptu test runs on the same day completely doable — a significant benefit, says Weselake.

“With this setup, I'm able to run more of a variety of materials 300 times faster using NVIDIA GPU accelerated computing. I can create presentations, compare intensities, and rank material options for glare and reflections. And very often, I'm able to do it on the same day I'm presenting the results, which is mind blowing.”

BMW door: comparison of the lighting intensity reflecting from the dark and light materials. (The lighting needs to be seven times brighter for black to have the same appearance.)

New Capabilities Lead to New Discoveries in the Material World

All this capability is a big thing for Weselake in terms of comparisons. Before using the setup with Speos software with NVIDIA accelerated computing, he was limited in his analysis to one material choice as an example. With this newfound capability, it's possible to test and compare material choices more extensively than before.

Speos software, when combined with NVIDIA GPU computing enabled Weselake to develop new methods to precisely position the symbols for the new BMW and Rolls-Royce clear steering wheel control buttons with regards to the refraction. These simulation capabilities helped Weselake to earn a patent for his procedure, cleverly using light to simulate vision.

Sometimes, insights coming out of Weselake’s simulation work led to new discoveries. While developing head-up displays (HUDs), for instance, he observed the behavior of unwanted stray rays.

“From this analysis with Speos software, I came to clearly realize the behavior of unwanted reflected rays and then make surfaces that could block them.”

MINI Window Controls: Lighting and reflection simulations for Night Design.

In the end, it’s big discoveries like these that can really make a difference in the BMW Group’s bottom line. For example, Speos helped Weselake discover a development issue with the Rolls-Royce Phantom HUD, if not uncovered, would have required a redo of the entire dashboard — basically the entire package — and all the tooling over a period of two years to the tune of tens of millions of euros.

"If I wrote a light software, I would do it exactly like the Speos solution, basically," concludes Weselake. "Everything makes sense to me, and it always has. Thanks to GPU computing, I can quickly simulate and evaluate a multitude of possibilities with nothing short of breathtaking results. When we later build up physical prototypes, as I arrive to look at them, I am always greeted with the comment: ‘It’s exactly like in your simulations!’”

To learn more about how Speos GPU empowers design exploration, watch the free on-demand webinar Speos GPU Empowers Design Exploration in Interactive Live Preview.

Just for you. We have some additional resources you may enjoy.

“When we later build up physical prototypes, as I arrive to look at them, I am always greeted with the comment: ‘It’s exactly like in your simulations!’”

— Kenneth Weselake, virtual validation project leader, BMW Group

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.