In last month’s press release, Ansys announced a groundbreaking collaboration with Volvo Cars and NVIDIA to revolutionize battery electric vehicle (BEV) development through GPU-accelerated computational fluid dynamics (CFD) simulations. The automotive industry is evolving rapidly, with BEVs at the forefront of innovation. Aerodynamic efficiency is one of the most significant factors influencing BEV performance, affecting energy consumption and driving range. To push the boundaries of vehicle design, leading automakers like Volvo Cars rely on high-fidelity CFD simulations. However, traditional CFD simulations are compute intensive, time-consuming, and costly, hindering fast design iterations and optimization studies.

Leveraging NVIDIA technologies with Volvo Cars, Ansys is transforming the landscape of BEV development by leveraging GPU-accelerated CFD simulations to drastically cut computation times. By integrating NVIDIA Blackwell Superchip into Ansys Fluent fluid simulation software, Ansys has enabled a 2.5X speedup in CFD simulation time for a Volvo EX90 BEV model compared to the same simulation run on 2,016 CPU cores and cost-equivalent hardware. This breakthrough enables engineers to reduce aerodynamic drag and extend vehicle range while streamlining product development cycles.

External aerodynamics simulation of the Volvo EX90

Accelerating Innovation: The Power of GPU-accelerated CFD

Volvo Cars’ commitment to innovation demands advanced computing solutions. High-fidelity CFD simulations play a crucial role in understanding and minimizing aerodynamic drag, a key factor in BEV efficiency. However, conventional simulation methods that rely on thousands of CPUs are slow and resource intensive, leaving little room for iterative design improvements.

To overcome these challenges, Volvo Cars and Ansys leveraged NVIDIA technologies to reduce total CFD simulation time from 24 hours on 2,016 CPU cores to just 6.5 hours — comprising a solve time of 5.5 hours on 8 NVIDIA Blackwell GPUs and 1 hour meshing time on CPU cores — thanks to NVIDIA GPU-accelerated Fluent fluid simulation and workflow optimizations.

“Using Ansys simulation has the potential to help our teams obtain favorable designs and carry out virtual testing in much less time than traditional approaches allow," said Torbjörn Virdung, technical leader, CFD, at Volvo Cars. "To make our products more efficient, we must first take stock of the tools and solutions we're using to get there. In this case, the capability of Ansys Fluent software can allow us not only to perform extremely high-fidelity analyses, but the added NVIDIA infrastructure supercharges the computation, so we can consider a greater number of design possibilities and reach an optimal car design faster."

This comparison is based on two hardware systems of equivalent cost, demonstrating the efficiency of NVIDIA GPU acceleration. This significant time reduction enables engineers to conduct multiple simulations daily, which accelerates the optimization process and helps achieve cutting-edge aerodynamic advancements.

Key Benefits of NVIDIA GPU-accelerated CFD

The primary advantage of NVIDIA GPU-accelerated CFD lies in its ability to significantly reduce simulation runtimes. Faster simulations lead to shorter design cycles, which speeds up Volvo Cars’ ability to bring energy-efficient vehicles to market.

The technology also enhances simulation accuracy by capturing complex fluid dynamics with high fidelity, which is critical for achieving superior aerodynamic performance in BEVs. By reducing dependence on physical wind tunnel testing, Volvo Cars can lower development costs while streamlining the certification process. Ultimately, NVIDIA GPU-accelerated CFD increases product development efficiency so Volvo Cars can optimize designs, improve vehicle range, and maintain a competitive edge in the quickly evolving automotive landscape.

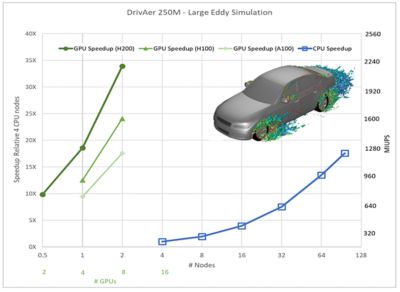

When running the standard benchmark DrivAer 250-million-cell model on different CPU and GPU configurations, our results show that two NVIDIA H200 GPUs achieved more than 10X greater performance compared with a four-CPU node system.

Transforming the Industry: Why This Matters Beyond Volvo Cars and Ansys

This breakthrough is not just a win for Volvo Cars — it is a milestone for the entire automotive industry. As sustainability and efficiency become top priorities, NVIDIA GPU-accelerated simulations pave the way for widespread innovation in vehicle aerodynamics. By making high-fidelity simulations faster and more accessible, this technology sets a new standard for BEV design by reducing energy consumption and promoting environmental responsibility.

Beyond automotive applications, GPU-accelerated CFD is poised to transform multiple industries that rely on high-fidelity fluid simulations. In the aerospace sector, this technology enables cheaper and more precise modeling of combustion, gas turbines, external aerodynamics, and aeroacoustics, enabling engineers to optimize aircraft efficiency and reduce noise emissions. In the energy industry, GPU-accelerated simulations improve the accuracy and speed of combustion and gas turbine studies, enhancing the design and performance of power generation systems.

Addressing Industry Challenges With Next-gen Computing

Before adopting GPU-accelerated simulations, automakers faced several challenges that hindered efficient vehicle development. Traditional CFD simulations, relying on thousands of CPUs, required excessive computation time that delayed product development and limited design iterations. Engineers needed faster simulations to test aerodynamic configurations and refine their designs within tight regulatory and market-driven deadlines. The high costs and time investments associated with physical wind tunnel testing further strained resources, making it an impractical solution for rapid design validation. Additionally, access to high-fidelity aerodynamic insights was often limited to specialist teams, which prevented broader innovation across the design process. Without efficient optimization tools, large-scale studies such as designs of experiments (DOEs) and parametric analyses took too long to be practical, slowing down the refinement of vehicle aerodynamics and energy efficiency.

By integrating Fluent fluid simulation with the NVIDIA Blackwell Superchip, Volvo Cars can successfully address these challenges to significantly accelerate the simulation process and unlock new possibilities for aerodynamic optimization. The ability to run complex CFD simulations in a fraction of the time enables engineers to evaluate multiple design iterations daily, making large-scale optimization studies a practical reality. This shift not only enhances product development but also reduces reliance on expensive physical testing. This leads to faster and more cost-effective vehicle innovations.

Leveraging NVIDIA technologies with Volvo Cars, Ansys is transforming the landscape of battery electric vehicle (BEV) development by using GPU-accelerated computational fluid dynamics (CFD) simulations to drastically cut computation times.

The Future of BEV Development With High-performance Computing

The impact of GPU-accelerated CFD simulations extends beyond Volvo Cars to influence the broader automotive ecosystem and set a new benchmark for BEV development. As automakers strive to improve efficiency and sustainability, high-performance computing (HPC) solutions are enabling next-generation vehicle design. By leveraging GPU-accelerated simulation software, automakers can reduce energy consumption, improve range, and enhance overall driving performance by optimizing vehicle aerodynamics. Faster simulations also enable manufacturers to streamline development cycles and bring energy-efficient vehicles to market more rapidly while maintaining regulatory compliance and competitive agility.

As the automotive industry continues its transition toward electrification, accelerated computing solutions will play an even greater role in shaping the vehicles of the future. Integrating AI-powered aerodynamic analysis and GPU-accelerated simulations democratizes access to high-fidelity insights, empowering engineers at all levels to contribute to innovation. With HPC at the core of BEV development, automakers can accelerate progress toward a more sustainable and efficient mobility future, driving the next wave of technological advancements in electric vehicles.

Learn more about the capabilities and advantages of GPU-accelerated CFD by visiting the Fluent GPU Solver FAQs, which provide detailed insights into how this technology is revolutionizing simulation workflows.

Just for you. We have some additional resources you may enjoy.

“Using Ansys simulation has the potential to help our teams obtain favorable designs and carry out virtual testing in much less time than traditional approaches allow."

— Torbjörn Virdung, Technical Leader, CFD, Volvo Cars