-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

In the world of engineering simulations, in which time and accuracy are critical, the need for high-performance computing (HPC) has never been more apparent. For users of Ansys Mechanical structural finite element analysis (FEA) software, one question often comes up: “Can GPUs accelerate my Mechanical simulations?” The answer is a resounding yes. Graphics processing units (GPUs) can significantly enhance Mechanical simulation performance, enabling engineers to achieve faster results without compromising accuracy.

A Brief History of GPU Acceleration

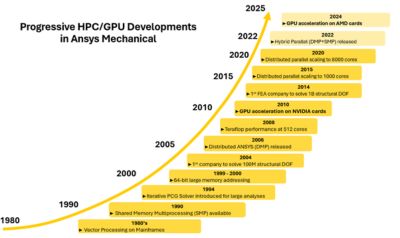

The journey of GPU acceleration in Mechanical software is a story of constant innovation. Mechanical APDL (Ansys Parametric Design Language) has long been a pioneer in adopting advanced parallel programming models. In 1990, Ansys introduced support for multiple CPUs, well before multithreading standards like OpenMP became widely recognized. By the early 2000s, Ansys took another leap by integrating distributed memory parallelism, leveraging message-passing interface (MPI) software to enable seamless data communication between CPUs.

The real revolution came in 2010, when Ansys became the first to commercially support GPU-accelerated simulations for Mechanical APDL. Starting with NVIDIA GPUs, this milestone made it possible to harness the immense computational power of GPUs to accelerate equation solvers and other critical simulation processes. Since then, the capabilities have only grown, offering robust support for a wide range of features, operating systems, and hardware platforms while maintaining the unparalleled precision that Ansys is renowned for.

What sets GPU acceleration in Ansys apart is its design philosophy. This feature is not a niche capability reserved for specialized applications. Instead, it is a powerful, scalable solution that integrates seamlessly with mainstream simulation workflows, delivering results with accuracy equivalent to traditional CPU-based computations.

Supported GPUs and How To Enable Them

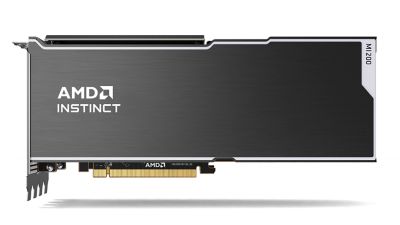

Mechanical APDL supports a range of GPU options from leading manufacturers, including NVIDIA and AMD. For NVIDIA users, high-end RTX graphics cards (previously branded as Quadro) or data center GPUs like the A100 or H100 are strongly recommended. On the AMD side, the MI Instinct series of GPUs provides optimal performance for accelerating simulations.

NVIDIA A100 PCIe GPU

AMD Instinct MI200

Enabling GPU acceleration is a straightforward process. For Mechanical software users accessing it through the Ansys Workbench platform, go to the Solution Process Settings dialog box. In the Advanced Settings section, select either NVIDIA or AMD GPU hardware from the dropdown menu. This configuration prompts the software to verify the GPU hardware, check for the required HPC licenses, and initiate GPU-based acceleration for solver calculations.

If you are using Mechanical APDL directly, enabling GPU acceleration involves adding the -ACC command line option when running simulations. These simple steps unlock the full potential of GPU acceleration, making it accessible to users across diverse workflows.

Learn About Equation Solvers and Simulation Types

Central to the power of GPU acceleration in Mechanical software are its equation solvers. Ansys offers two primary solvers: a direct solver and an iterative solver.

Both solvers can leverage GPU hardware to significantly speed up calculations. In addition to traditional simulations, modes like modal and buckling analyses can benefit from GPU acceleration. Models that spend a substantial portion of their simulation time within these solvers — such as those with complex geometries, refined meshes, or high degrees of freedom — are ideal candidates for GPU acceleration.

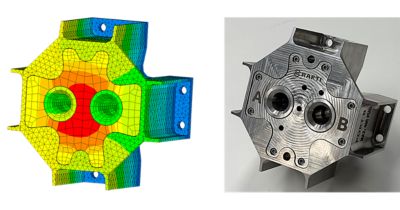

For example, bulky 3D models or those with higher-order elements typically involve dense finite element matrices. These models naturally demand more computational resources during the equation-solving phase, making them prime candidates for GPU acceleration. By offloading these calculations to GPUs, users can achieve significant time savings while maintaining high accuracy.

Selecting the Right GPU

Choosing the right GPU for your simulation needs is a critical decision. Not all GPUs are created equal, and the performance gains you achieve depend heavily on the hardware’s capabilities. Here are the key factors to consider when selecting a GPU:

- Double precision compute capability: Essential for ensuring the accuracy of engineering simulations

- Memory capacity and bandwidth: Large models require GPUs with high memory capacity and bandwidth to handle complex calculations efficiently

- Support for newer PCIe standards: Faster data transfer between the CPU and GPU minimizes latency and improves overall simulation speed

The Ansys installation guide provides a comprehensive list of recommended GPUs, including specifications like memory capacity, compute speed, and estimated costs. High-end GPUs, such as NVIDIA’s A100 and H100 or AMD’s Instinct MI210, stand out for their superior double-precision performance, making them excellent choices for demanding simulations.

Examining Performance Benchmarks

The impact of GPU acceleration on simulation performance is best illustrated through benchmarks. Let’s look at a couple of examples:

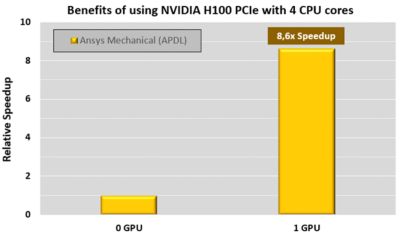

- Direct solver performance: A 3D engine block model, meshed with solid elements, was tested using an NVIDIA H100 GPU. The results showed an impressive 8.6X speedup in equation solver performance compared with CPU-only calculations.

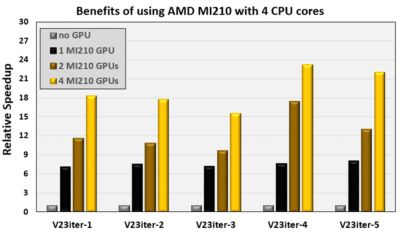

- Iterative solver performance: Benchmarks with AMD’s MI210 GPUs highlighted the scalability of GPU acceleration. Using one, two, and four GPUs in tandem demonstrated progressively higher performance gains for iterative solvers. This scalability allows users to tailor hardware configurations to their specific performance needs.

Achieve 8.6X faster Ansys Mechanical solver performance on four CPU cores with NVIDIA H100 PCIe.

Achieve up to 24X faster Mechanical solver performance on four CPU cores with four AMD MI210 GPUs.

These examples underscore the transformative potential of GPU acceleration. By reducing the time required for complex simulations, GPUs empower engineers to explore more design iterations, optimize workflows, and bring products to market faster.

Why GPU Acceleration Matters

The benefits of GPU acceleration go beyond just speed. In today’s fast-paced engineering environments, time savings translate directly into competitive advantages. By enabling faster simulations, GPUs enable engineers to:

- Perform more design iterations in less time

- Simulate larger, more detailed models that were previously computationally prohibitive

- Accelerate critical workflows, from product design to validation

Moreover, GPU acceleration reduces the bottlenecks associated with traditional CPU-based simulations, ensuring that computational resources are used efficiently.

Getting Started With GPU Acceleration

Implementing GPU acceleration in your Mechanical simulations is easier than you might think. Start by:

- Reviewing the hardware requirements and selecting a recommended GPU

- Configuring the necessary settings in the Workbench platform or Mechanical APDL

- Running test simulations to benchmark performance improvements

For users who are new to GPU acceleration, Ansys offers comprehensive documentation and support resources to guide you through the setup process. Additionally, engaging with the Ansys user community can provide valuable insights and best practices.

Discover the GPU Advantage With Ansys

GPU acceleration is a game-changer for Mechanical software users. By leveraging the power of GPUs, engineers can tackle larger, more complex simulations with unprecedented speed and efficiency. Whether you’re working on 3D models with refined meshes or exploring new design possibilities, GPUs offer the computational muscle needed to push boundaries and achieve better results.

Watch this video with Jeff Beisheim, senior principal R&D engineer at Ansys, in which he helps you make informed decisions on your next GPU investment. And lastly, don’t forget to explore the resources available on the Ansys website to start accelerating your simulations today.

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.