In early January 2024, 20 students and staff members from the Aerospace Systems Research Institute (ASRI) traveled to Orlando, Florida.

The team was excited to share its expertise by participating in the American Institute of Aeronautics and Astronautics (AIAA) 2024 SciTech aerospace conference, one of the largest global aerospace conferences. During the five days of the conference, the ASRI team delivered 15 papers, sharing its important work with an international audience.

The Aerospace Systems Research Institute (ASRI) team at the American Institute of Aeronautics and Astronautics (AIAA) conference

This trip helped ASRI take one step closer to achieving its ambitious goals. One of its targets is developing “a sovereign launch capability for South Africa and Africa,” says Nino Wunderlin, a senior engineering staff member at ASRI who primarily focuses on propulsion and the thermo-structural design of rocket propulsion elements. “We want to develop the technology and the skilled human capital (needed) to achieve this ultimate goal.” As part of this objective, the ASRI team is also focused on developing and producing an industrial manufacturing base and highly complex rocket components.

Achieving these goals will not be simple, but ASRI is ready to take on this challenge through a few key projects that the team is pursuing.

Ready for Launch: Exploring Two Exciting Projects in Development at ASRI

Sounding rockets are an integral part of developing our global space industry. Engineers use sounding rockets to launch experiments to the very edge of space before letting the rockets free-fall back to Earth. In doing so, they help researchers investigate phenomena like microgravity, generating information that can be used to improve future missions.

The ASRI team has worked on sounding rockets for years through its Phoenix Hybrid Sounding Rocket Program (HSRP), which is in its seventh iteration. The Phoenix HSRP not only serves to advance propulsion technology, vehicle design, and motor fabrication but helps develop the ASRI team and inspire the next generation of space innovators. A key objective of the Phoenix HSRP is to create civilian sounding rockets that fulfill South African and African scientific community requirements. Wunderlin has been working on the rocket since its third iteration, focusing on assisting in the design and structural optimization of Phoenix’s combustion chamber, nozzle, and fin assembly.

Already, Phoenix is breaking records. For instance, Wunderlin shares that his proudest moment as part of this project “was when we broke the African Hybrid altitude record when Phoenix flew to 18 km.” Looking ahead, ASRI hopes to use this project as a cornerstone on the path to deploying a 100 km apogee sounding rocket that the entire African physics community can use.

A rocket launch

ASRI is also pushing the boundaries of engine design with its South African First Rocket Engine (SAFFIRE) project, which is the primary focus for Wunderlin and a large portion of the wider ASRI team.

SAFFIRE is a 27 kilonewton (kN) pump-fed liquid propellant rocket engine that uses kerosene and liquid oxygen-driven electro-pumps and is designed to be the power plant for a sovereign orbital-class vehicle. One of the main benefits of SAFFIRE is its modular, compact nature, which enables it to be used as part of various configurations and launch vehicles. As a result, SAFFIRE has a wide array of potential applications, one of which is providing a low-cost option for deploying CubeSats into low Earth orbit (LEO).

“This work in particular is the most exciting for me because there is no other place in South Africa where this cutting-edge technology is being worked on, and we are at the forefront of what South African industry can provide,” says Wunderlin. With SAFFIRE, ASRI has the potential to bolster SmallSat launch vehicle capabilities throughout the entire continent of Africa.

ASRI testing its designs

To continue progressing toward its goals and advancing its technology, ASRI is working to overcome a few main obstacles, one of which is addressing the inherently challenging nature of developing space-rated products. “You very rarely get a second chance when testing your components,” says Wunderlin. “Either they work, or they don’t.” To minimize risk and ensure first-time-right design, ASRI turns to simulation software.

ASRI Turns to Simulation for Designing, Manufacturing, and Testing

As an Ansys Student Team Partner, ASRI has access to what Wunderlin describes as a “broad and well-connected ecosystem” of simulation products — including Ansys Mechanical structural finite element analysis (FEA) software, the Ansys Composite PrepPost (ACP) tool, the Ansys Material Designer solution, and Ansys Fluent fluid simulation software — that empower it to excel. “With our limited resources, Ansys has been an invaluable tool for us as it allows us to check and simulate everything, even before the components are sent for manufacturing,” says Wunderlin. “It has allowed us to cut down on development time and testing numerous physical iterations, which can be prohibitively expensive.”

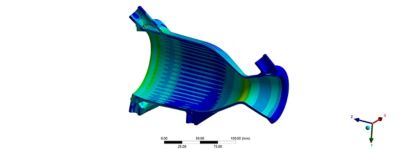

As one example of its simulation work, consider ASRI’s use of Mechanical software and the ACP tool to conduct high-fidelity FEAs. Using Ansys simulation solutions accessed through the Ansys Academic Program, the ASRI team can thoroughly study critical components and analyze structural integrity, vibrational modes, and more — even for the challenging composite materials from which both SAFFIRE and Phoenix are primarily constructed. “The Ansys ACP tool, coupled with Mechanical software, allows us to design the most structurally and thermally efficient components,” says Wunderlin.

A chamber equivalent stress finite element analysis (FEA)

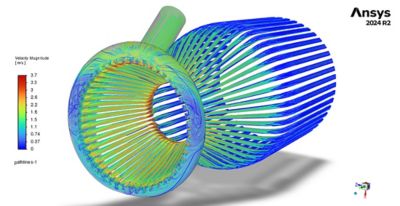

As for Fluent software, ASRI uses this product to determine the external drag and aerodynamic loading conditions of its designs. The results are then used as the inputs for a structural verification analysis performed via Mechanical software. ASRI also uses Fluent software for combustion simulations and to study internal flow when designing injectors and regenerative cooling passages. The ability to combine multiple Ansys solutions is a key benefit for ASRI. Doing so “allows us to seamlessly perform thermo-structural analyses and (study) fluid-structural interactions (FSIs), which other software does not do with such ease,” says Wunderlin.

ASRI was also able to use Fluent software with the Ansys Technology Partner CFturbo to aid in the development of the turbo machinery in SAFFIRE’s pumps. Additionally, the team’s work was supported by Qfinsoft, an Ansys Channel Partner.

A velocity magnitude analysis

Reflecting on the use of simulation throughout ASRI’s work, Wunderlin shares that, “fundamentally, Ansys software is used for most mission-critical components.” Throughout ASRI’s MSc program, it encourages using Ansys simulation since that “directly assists with the research goals of the institute,” Wunderlin says.

Advancing Technologies and Fostering a Thriving Aerospace Community in South Africa

To break the space boundary, ASRI needs to develop extremely structurally efficient vehicles. “Every gram that can be shaved off must be shaved off,” says Wunderlin. Simulation software helps ASRI achieve this goal. For instance, the use of sophisticated modeling approaches, along with new manufacturing techniques and materials, enabled the ASRI team to eliminate 75% of the original mass of Phoenix’s combustion chamber, nozzle, and fin assembly.

Ansys simulation solutions have also benefited ASRI’s R&D schedules. Ansys “has allowed us to simulate everything and verify the designs before the components even touch the test stands,” says Wunderlin. “I would estimate that the use of Ansys products has reduced the development time by 65%.” This large improvement in ASRI’s rate of development was aided by its Ansys Student Team Partnership, which granted ASRI access to an increased number of seats and different software products. “We would not be anywhere close to where we are now if it wasn’t for the partnership,” Wunderlin says.

Not only has its work seen great advancements — the ASRI team hopes to advance the aerospace field at large. “We believe that the work we are doing will be extremely beneficial for not only South Africa but Africa as a whole,” says Wunderlin. “We believe that this program will help develop South Africa’s advanced manufacturing base and also inspire young students and engineers to pursue a career in aerospace engineering.”

Learn more about an Ansys Student Team Partnership to see how Ansys empowers student teams with cutting-edge simulation tools and resources.

Just for you. We have some additional resources you may enjoy.

“I would estimate that the use of Ansys products has reduced the development time by 65%.”

— Nino Wunderlin, senior engineering staff member, Aerospace Systems Research Institute (ASRI)