Case Study

-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

“Ansys simulation made it possible to identify the central cost drivers in relation to the return on investment (ROI) of a robotic welding system for additive manufacturing. This opens the way for future research. In addition, the evaluation of the economic analysis could be carried out in a time- and cost- optimized way. A qualitatively equivalent manual evaluation without the support of Ansys simulation would not have been possible. With Ansys simulation, a static one-dimensional calculation model became a dynamic multidimensional model.”

— Korbinian Mühlhauser

Welding Engineer, Linde Engineering

Linde Enhances Economic Analyses with Cost-effective Optimization

Linde Engineering (Linde) has been developing and optimizing gas processing, separation, and liquefication technologies for 140 years. With material costs rising over time, Linde is exploring alternative development and production methods to work more efficiently. This has led to a recent economic analysis of an additive arc manufacturing process for aluminum components in plant and pressure vessel construction. Linde implemented Ansys simulation into their economic analysis to optimize data analyses, automate parameter identification, and visualize results. By integrating Ansys simulation, Linde was able to explore potential issues in a much more dynamic and multidimensional way.

Challenges

While preparing the economic analysis in a spreadsheet, the Linde team realized that a static calculation could only include a very specific combination of parameters. The group needed a program that would allow team members to vary parameters automatically. By incorporating optiSLang into the analysis project, Linde was able to achieve this. Additionally, the software offered user-friendly interfaces and provided numerous possibilities for evaluating data?

1. Figure 1. A Linde welder produces Figure fillet welds.

Engineering Solutions

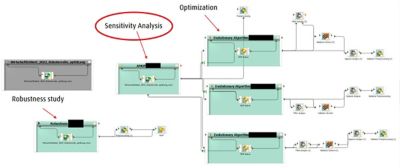

First, Linde prepared a detailed economic analysis in a spreadsheet program, which contained 36 parameters of mostly variable inputs for costs (e.g., electricity, material, and labor), times (e.g., tool setup and weld path planning), and technology (e.g., melting rate and shielding gas flow). In addition, Linde wanted to observe the differences across one-, two-, and three-shift operational systems. With so many combinations and variables to explore, manually changing parameters was not practical. For this reason, Linde integrated the spreadsheet file into optiSLang to carry out a more in-depth sensitivity study and evaluate the results for both time and cost.

Figure 2. Linde applied Ansys optiSLang to conduct a thorough economic analysis of an additive arc.

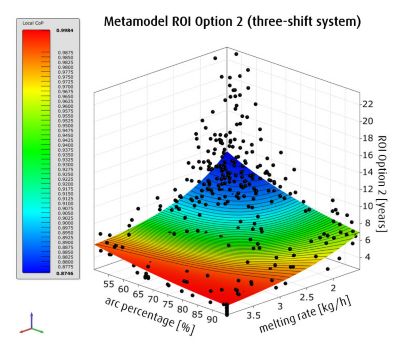

By illustrating their findings through advanced 3D visualizations, Linde was able to see correlations and discrepancies that are not apparent in a spreadsheet analysis. With the Ansys-powered sensitivity study, Linde identified the most important factors influencing the return on investment (ROI) of a potential robotic welding system for additive manufacturing.

Figure 3. Linde integrated a spreadsheet program file into optiSLang to perform a sensitivity.

Benefits

- Ansys optiSLang enabled Linde to enhance economic analyses and achieve fast and cost-effective optimization through metamodeling, graphically illustrating correlations that are not readily apparent in a spreadsheet report.

- The coefficient of prognosis (CoP) matrix model in optiSLang displayed the percentage influence of various input parameters in relation to selected output parameters, enabling Linde to gain critical insights that included ROI, machine utilization, and savings per year. This empowered Linde to explore future scenarios and analyses.

- Spreadsheet calculations took approximately five minutes each, depending on the shift system (one, two, or three shifts). Therefore, a simulation with 300 iterations was easily achieved within 25 hours by integrating optiSLang. Linde notes that if the integrated solver (the spreadsheet program) was more powerful, the overall completion time would have been less.

Figure 4. Metamodeling in optiSLang enabled Linde analysts to gain economic insights for one-, two-, and three-shift operational systems, including return on investment (ROI), machine utilization, and savings per year.

Figure 5. Figure 5. A Linde worker welds a stainless steel vessel.

Let’s Get Started

If you're facing engineering challenges, our team is here to assist. With a wealth of experience and a commitment to innovation, we invite you to reach out to us. Let's collaborate to turn your engineering obstacles into opportunities for growth and success. Contact us today to start the conversation.