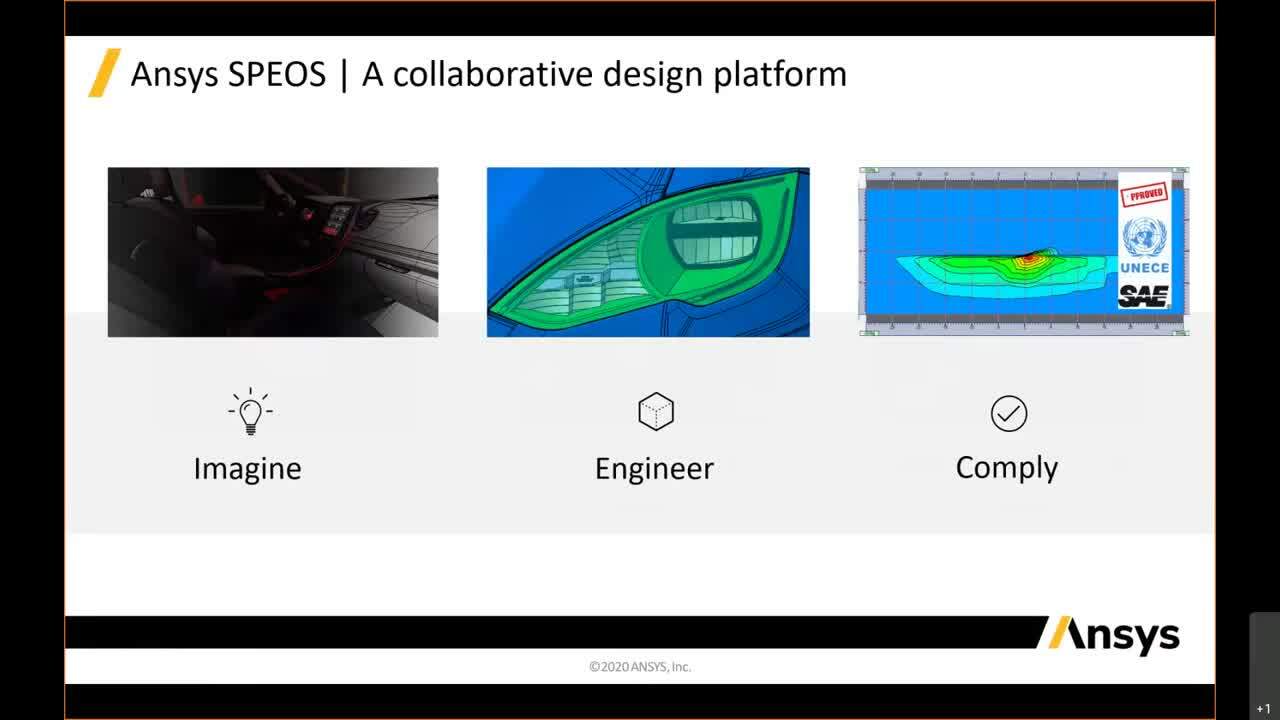

Quick Specs

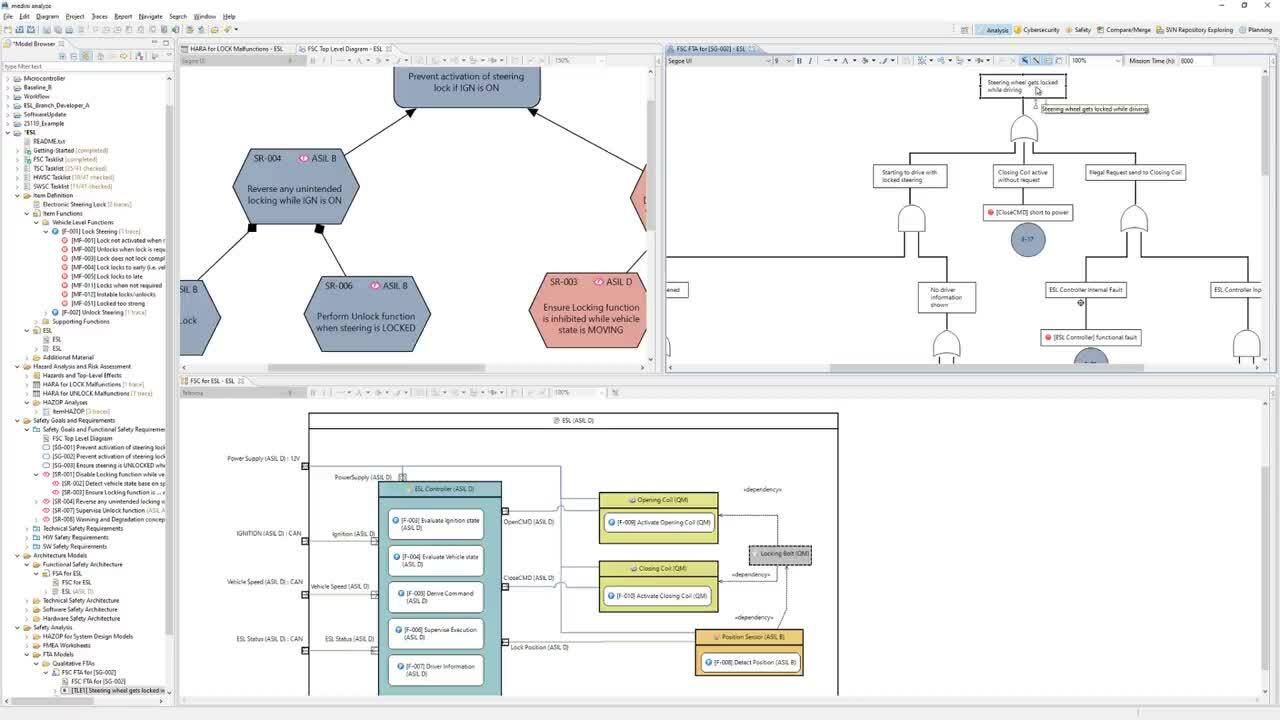

With Ansys medini analyze, inconsistencies in the functional safety analysis are eliminated, and the certification process is accelerated. Engineers can recognize up to a 50% decrease in efforts for functional safety analysis and a similar decrease in time to market.