Case Study

-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

“Utilizing Ansys Mechanical and Sherlock analysis has been instrumental for us in aligning environmental test outcomes with analysis data. This correlation has proven essential in pinpointing potential failure modes throughout our product development phase. It's become indispensable in our design cycle, ensuring our product aligns with the rigorous demands of the space environment. Qfinsoft has also played a crucial role, not just in providing the necessary tools but also in offering valuable support and guidance to our engineers.”

— Shane Martin, Mechanical Design Lead, NewSpace Systems

Challenges

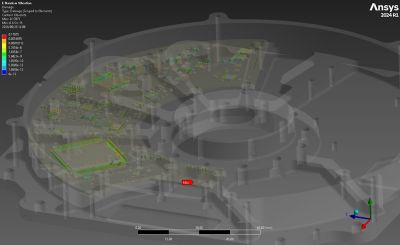

During the development phase of a new reaction wheel, an electronic device failure was identified during vibration testing. Ansys Sherlock reliability analysis software was used to simulate the vibration environment on the printed circuit board (PCB), which identified the root cause of the failure to be due to a specific resonant mode on the PCB, which coupled with that of the chassis.

Figure 1. Fatigue damage assessment on PCB

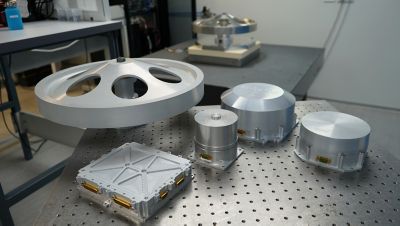

Figure 2. Reaction wheel production in cleanroom

Engineering Solutions

To address the failure mode of the component, NSS followed a combination of two solutions. The first was to add additional mounting points to the components’ PCB to increase the frequency of its resonant mode so that it fell outside of the damaging vibration spectrum. Secondly, the chassis the PCB was secured to was stiffened to increase its resonant mode and reduce the deflection of the chassis under vibration. NSS assessed and optimized the combination of these solutions with Ansys Mechanical structural simulation software’s random vibration analysis on the chassis and PCB. They then assessed both the total deflection of the chassis and fatigue lifetime of the leads of the electronic components.

Figure 3. NSS reaction wheel family

Benefits

By being able to simulate both the original design and the new, optimized design, NSS implemented engineering improvements that reduced the chassis deflection by 24% and increased the fatigue lifetime of the electronics by 686%. The new solution was then manufactured and tested successfully.

Let’s Get Started

If you're facing engineering challenges, our team is here to assist. With a wealth of experience and a commitment to innovation, we invite you to reach out to us. Let's collaborate to turn your engineering obstacles into opportunities for growth and success. Contact us today to start the conversation.