Determine the electronics reliability workflow that works for you and your team

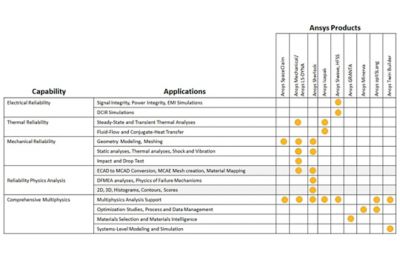

Simulation isn’t a one size fits all. That’s why Ansys provides multiple electronics reliability workflows to fit your product and your reliability needs.

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Students get free access to world-class simulation software.

Connect with Ansys to explore how simulation can power your next breakthrough.

Solve your biggest thermal, electrical and mechanical reliability challenges.

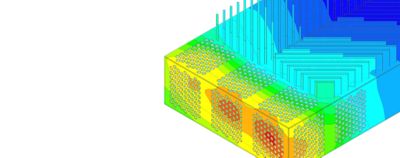

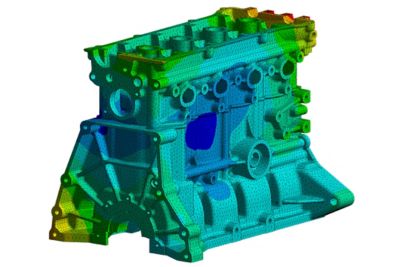

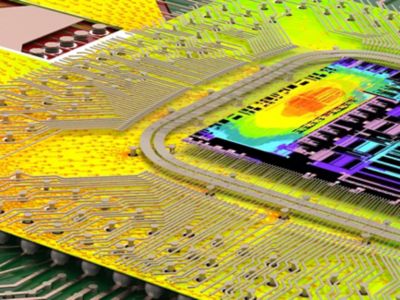

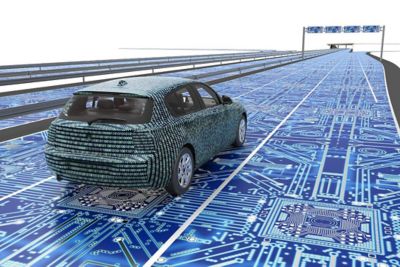

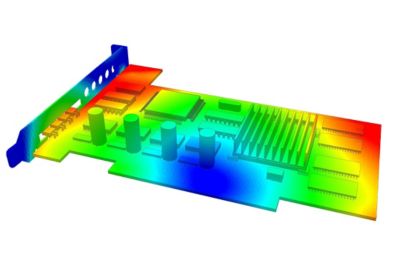

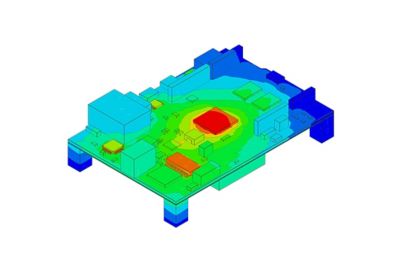

Best practices for ensuring and predicting electronics reliability require comprehensive multi-physics simulations. Ansys ensures reliability success by developing solutions and workflows that overcome today’s biggest simulation and design challenges.

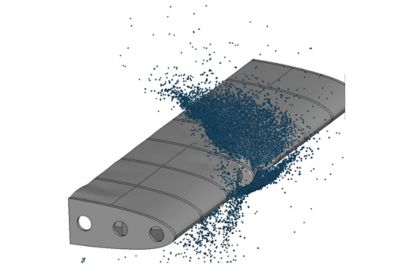

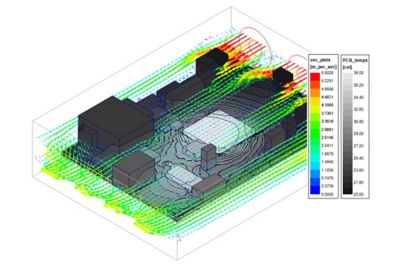

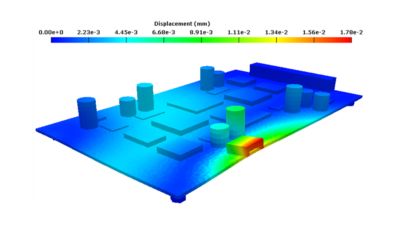

Ansys electronics reliability workflows help you overcome numerous electrical, thermal and mechanical reliability challenges. This enables you to boost signal integrity, protect against shock and vibration failure, eliminate electromagnetic interference and much more. Watch this dynamic video to learn how you can leverage Ansys electronics reliability workflows to help ensure your product will perform as promised — before it goes to market.

Ansys Electronics Reliability solutions allow organizations to capture a wide-range of parts, materials, simulation and other data, as well as access to critical, simulation-ready material and component data.

Reliability predictions based on physics of failure (PoF) principles resides at the core of the Ansys Electronics Reliability portfolio. Using Ansys simulation tools, electronics manufacturers can determine how long it takes for a product to fail and why the failure occurred.

Ansys Electronics Reliability tools allow engineers to create comprehensive simulation workflows that include high-levels of automation.

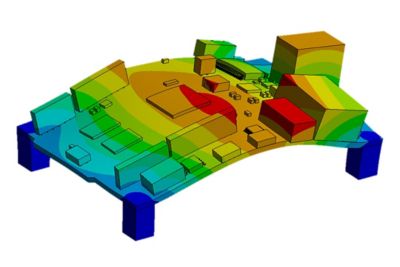

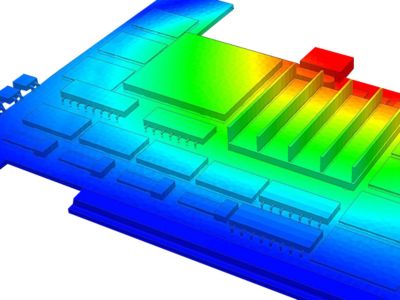

Integrated workflows between Ansys Sherlock, Icepak, Mechanical, LS-DYNA, and more provide the simulation results necessary to optimize product designs and ensure reliability in the field.

“Across the board, it doesn't matter what tech trend you're looking at—5G, electrification, AVs, IIoT—PCB reliability is at the backbone of all those needs."

Carlos Gomez, Lead Application Engineer, Ansys Icepak

Simulation isn’t a one size fits all. That’s why Ansys provides multiple electronics reliability workflows to fit your product and your reliability needs.

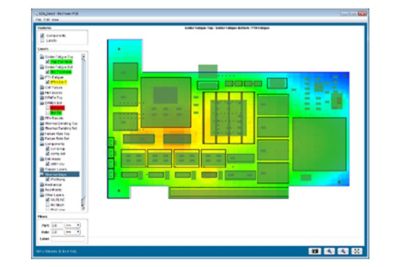

Ansys solutions for PCB reliability include a multi-physics workflow that uses a suite of leading simulation tools. Using our workflow solutions, you can simulate electrical, thermal, and mechanical effects to determine product reliability.

Continental Automotive Tests its Product Reliability in a Fraction of Time Before Building Prototype

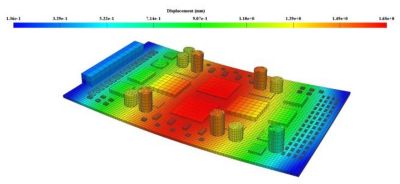

Continental Automotive used Sherlock to evaluate and identify a superior adhesive material before building the prototype. Key findings include: * Superior adhesive material – the BGA survived for much longer when this material was applied, as opposed to using other adhesives. * Increasing the thermocycling frequency of the customer-provided field temperature profile decreased the BGA life by half * Adding the 15°C rise in BGA temperature (due to the component power dissipation) to the field environment profiles resulted in an even lower time to failure

This webinar will demonstrate an automated process of thermal modeling of printed circuit boards. It will present a workflow to translate ECAD data to a thermal and mechanical model in Ansys Icepak, followed by the transfer of results into Ansys Sherlock for solder fatigue analysis.

This webinar covers product integrations, relevant updates for each tool that will enable faster and more efficient simulations and updates to key workflows that help users address important electronics reliability challenges.

If you're facing engineering challenges, our team is here to assist. With a wealth of experience and a commitment to innovation, we invite you to reach out to us. Let's collaborate to turn your engineering obstacles into opportunities for growth and success. Contact us today to start the conversation.