-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

ANSYS BLOG

August 26, 2019

How to Ensure Electronic Product Reliability When You Don’t Have Time to Test

With today’s rapid product development and time-to-market pressures, engineers find that there isn’t a lot of time to perform reliability tests.

So, how do engineers ensure that their products are dependable when reliability testing and possible redesigns are time-consuming or expensive?

In these situations, the key to reliable products is to employ design for reliability (DfR) methodologies. DfR is a process that ensures a product, or system, will perform a specified function, within a defined environment, over an expected lifetime.

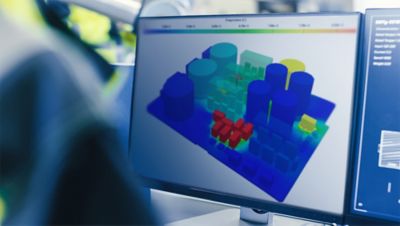

Rapid product development can make it challenging to ensure product reliability without DfR.

DfR occurs at the design stage, when engineers start assessing a concept’s feasibility — well before the construction of physical prototypes. It is often part of an overall design for excellence (DfX) strategy. In addition to the obvious mechanical considerations, DfR needs to consider:

- Electrical/software reliability

- Supplier and part selection

- Design for manufacturing (DfM)

- Physics of failure (PoF) analysis/modeling

Ensure Electronic Product Reliability with DfR: Goal Setting

Not every product needs to achieve the same level of reliability to meet customer expectations. This concept can be described using four broad product reliability categories:

- Low-end consumer products (like toys, pedometers, etc.)

- Mainstream consumer electronics (like cellphones and computers)

- Commercial electronics (like high-end servers and industrial controls)

- Highly regulated electronics (like avionic and telecommunication equipment)

As a part of DfR, engineers need to set goals if they plan to meet the expectations of customers.

To ensure that electronic product reliability meets customer expectations, engineers must establish the desired product lifetime and performance during the concept phase. This important step drives the thinking behind every decision throughout the product development process.

As an example of product reliability goals, engineers could set expectations that a product should have 95% reliability with a 90% confidence level over 15 years.

Engineers also need to establish the field environment — which defines the environment the product will operate in. The field environment can be determined based on actual measurements, data from similar products or industry specifications. The latter approach is best if time and costs are severe constraints.

Engineers also have to ensure that products meet the specification standards throughout industry, such as:

- MIL-STD-810

- MIL-HDBK-310

- IPC-SM-785

- Telcordia GR3108

- IEC 60721-3

Ensure Electronic Product Reliability with DfR: Initial Designs

Engineers can address many reliability problems in the initial designs of a product.

For instance, a large number of hardware reliability problems are driven by arbitrary size constraints that are set too early in the design phase. These early decisions can cause problems like poor interconnections and component selections. Therefore, DfR strategies suggest keeping dimensions loose in the initial design stages.

Engineers can address many electronic product reliability issues early in development.

Reliability problems can also stem from the inadequate analysis of electrical impacts early in design. That is why DfR strategies assess the power stability concerns of various markets worldwide. For example, some locations in the world can experience issues with:

- Grounding

- Brownouts

- Voltage surges

Furthermore, DfR considers electrostatic discharge (ESD), electromagnetic compatibility (EMC) and electromagnetic interference (EMI) from a regulatory and product performance perspective. As a result, engineers will be better equipped to assess these electrical challenges early in development.

Ensure Electronic Product Reliability with DfR: Supplier and Component Selection

DfR methodologies note that supplier selections play a critical role in the success, or failure, of the product.

Original equipment manufacturers (OEMs) must find suppliers that align with a product’s design, functionality and requirements. These partners must also deliver quality products and services without interruption.

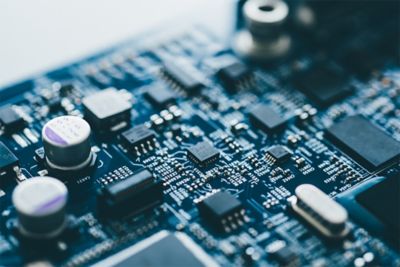

DfR strategies state that supplier and component selection can make or break a design.

Engineers who unwittingly engage with manufacturers that lack these capabilities dramatically increase the potential for defects in their products. These defects can result in expensive warranty claims, loss of market share and possible irreparable damage to a brand.

Component selection is equally important and has several aspects. First, keep it simple. New technology can be attractive, but it is not always appropriate for highly reliable systems. Be conservative, but not overly so as older technologies also come with risks — like market disruptions and counterfeits.

Next, engineers need to employ a strategy of component derating. Derating is the practice of limiting stress on electronic parts to levels below the manufacturer’s specified ratings.

Derating guidelines vary based upon the environment. For example, a part in space has different guidelines than a part in a phone. Derating must have a practical or scientific foundation. Thus, component derating should be assessed through component stress analyses. Sources for derating guidelines include governmental organizations, third parties, OEMs and component manufacturers.

Ensure Electronic Product Reliability with DfR: Design for Manufacturing

The next step in a DfR is the DfM. DfM is the process of ensuring a product can be consistently manufactured by the designated supply chain with a minimum number of defects.

DfM works best when there is an understanding of best practices. Ask questions like:

- What fails during manufacturing?

- How can manufacturers avoid failure?

- What are the limitations of the supply chain?

DfR and DfM helps engineers ensure that parts are manufactured properly.

DfM includes a variety of tools and processes. Not all of them will apply to an engineer’s product. Best practices call for using or modifying a DfM checklist to ensure all items related to a specific product’s board, system and assembly meet the requirements. One checklist example might include (but is not limited to):

- Baseline

- Matches a design’s capabilities

- Ensures the design is transferable

- Board

- Trace width and spacings

- Laminate material

- Ensure stackup symmetry

- Note the complexity of via connections

- Incorporate new materials (embedded passives)

- Assess each side (single-sided vs. double-sided boards)

- System

- Note blind connections

- Note Z-dimension limitations

- Assembly

- Eliminate hand soldering or wave soldering when possible

- Avoid the proximity of components to flexpoints

- Ensure component spacing

- Verify the size of components and complexity of packaging

- Orient components to the wave solder

- Shadow during wave solder

- Set the dimensions and spacings for plated through-holes (PTHs) and bond pads

- Note attachment methods

- Assess moisture sensitivity level (MSL)

Using DfM, engineers can discover and address many manufacturing and handling issues — like when component fractures are caused by excessive board flexing during production. Other processes of concern can include:

- Depaneling

- In-circuit testing (ICT)

- Screw attachments

- Connector or daughter card insertions

- Attaching structures (such as heat sinks, covers or plates)

Engineers need to evaluate how every assembly process affects the design. Until recently, such analyses were problematic due to cost and time restraints. However, fast and cost-effective tools like Ansys Sherlock’s ICT module can perform analyses in a few minutes.

Ensure Electronic Product Reliability with DfR: Physics of Failure

Companies need powerful algorithms and tools to accurately predict the probability of failure over the lifetime of their products. Even cell phones with power amplifiers, high power cycles and dissipation can wear out in three years.

Over the past two decades, sophisticated PoF models have been developed for the DfR process. These models can assess:

- Solder fatigue

- Thermomechanical power cycling

- Mechanical shock

- Vibration

If such capabilities are not available in-house, they can be done using Ansys Sherlock.

How to Join the Ranks of the Best in Class DfR Companies

The companies that exhibit best-in-class DfR are able to ensure product reliability. To get started in the DfR process, follow these guidelines:

- Don’t paint yourself into a corner too early in the design process

- Be aware of all requirements

- Ensure design teams with different specialties work concurrently with plenty of collaboration

- Use a design checklist

- Don’t just rely on physical tests for:

- Part selection

- Derating

- Power stability

- ESD/EMI/EMC

- DfM

- Components testing

When engineers include a thorough test plan as part of the design phase, they are better able to ensure product reliability and success.

Learn More

Let Ansys help you with your toughest electronics reliability challenges. Learn about our Reliability Engineering Services.