Quick Specs

Perform in depth calculations with the industry-leading in-flight icing simulator. This powerful and streamlined software allows you to analyze ice accretion and ice protection systems.

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Students get free access to world-class simulation software.

Connect with Ansys to explore how simulation can power your next breakthrough.

Ansys FENSAP-ICE gives you a reliable method to simulate and analyze in-flight icing and ice accretion for a variety of aeronautical applications.

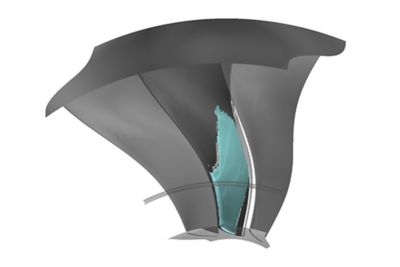

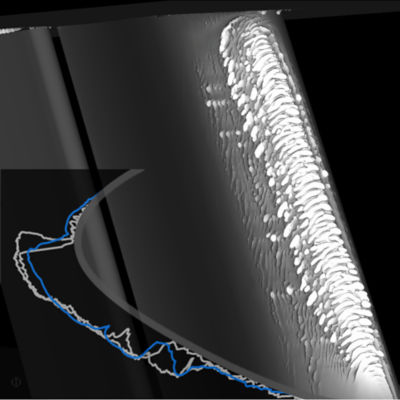

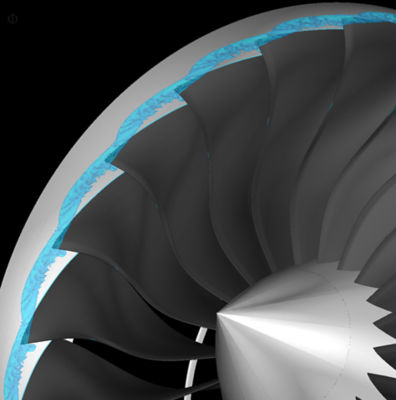

Ice accretion is a complex phenomenon that is extremely difficult to replicate using physical testing. Yet it’s essential to understand and limit for safety, product performance, and strict regulations. FENSAP-ICE brings you convenience by encompassing all major aspects of in-flight icing. Having no significant geometric limitations, it is applicable to aircraft, rotorcraft, UAVs, jet engines, nacelles, probes, detectors and other installed systems.

Perform in depth calculations with the industry-leading in-flight icing simulator. This powerful and streamlined software allows you to analyze ice accretion and ice protection systems.

July 2024

In 2024 R2, FENSAP-ICE has improved connections with Ansys Fluent, provides a new ice density model, and much more.

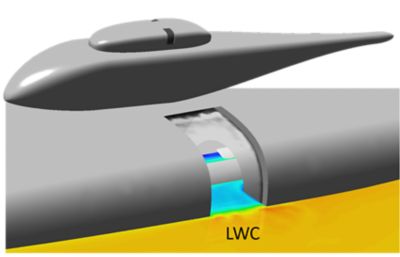

FENSAP-ICE now supports grids created with Fluent meshing workflows with generic boundary names in the MULTI_FLUENT run type, simplifying the pre-processing effort when Fluent is used as the flow solver.

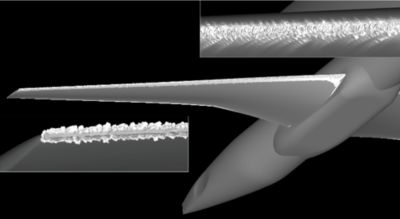

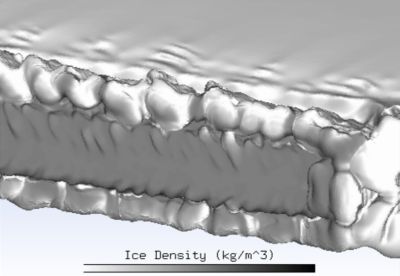

The impact ice density model, essential for swept wing ice shapes, is now available with tunable parameters and improved rime ice accuracy.

A minimum local time step control added to DROP3D avoids having the solution getting stuck with unphysical liquid water content (LWC) and melt fraction ratios in certain parts of the boundary layer.

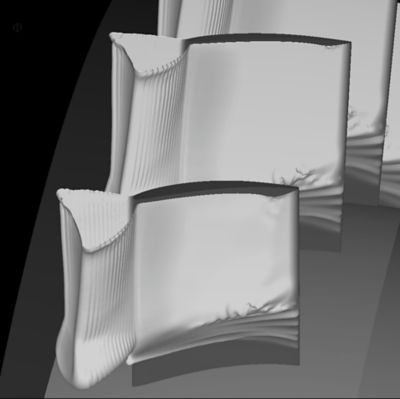

FENSAP-ICE can now run with negative volume elements to enhance the robustness of multi-shot icing simulations. The multi-shot runs are now more resilient to meshing artifacts.

The excess water film clipping model is updated to apply water sink only where it stagnates, improving runback film accuracy and mass conservation. The film detachment model is updated with a more accurate formula which is also quicker to evaluate. With these updates, water film shedding on rotating components can be resolved more accurately.

The remeshing process is updated to better handle ice shapes that intersect with other nearby boundaries which can be problematic during the surface wrap procedure. Icing simulations on internal components like turbomachinery blades are now more robust, with better handling of ice – shroud intersections.

Ansys FENSAP-ICE reduces your workload by providing powerful solvers dedicated to in-flight icing. Relying solely on experimental testing can add serious time and cost to a project. It can also be extremely difficult to consistently reproduce precise test conditions. This software lets you to accurately evaluate a variety of physical conditions while evaluating complex physics, such as conjugating heat transfer, prior to manufacturing. Fensap Ice gives you more time to analyze results and focus on critical design decisions.

Ansys Fensap Ice addresses all major in-flight icing phenomena and can help shorten your design cycle.

It's vital to Ansys that all users, including those with disabilities, can access our products. As such, we endeavor to follow accessibility requirements based on the US Access Board (Section 508), Web Content Accessibility Guidelines (WCAG), and the current format of the Voluntary Product Accessibility Template (VPAT).

If you're facing engineering challenges, our team is here to assist. With a wealth of experience and a commitment to innovation, we invite you to reach out to us. Let's collaborate to turn your engineering obstacles into opportunities for growth and success. Contact us today to start the conversation.