-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

Semiconductor manufacturers must identify next-generation materials that maximize efficiency, minimize losses, and extend product life.

Headquartered in Scottsdale, Arizona, onsemi is a leading global semiconductor manufacturer, with more than 60 fabrication sites and design centers spanning 19 countries. Like other semiconductor companies, onsemi faces pressure to produce consistently more capable designs that are also small, cost-effective, sustainable, and energy-efficient. In addition, its solutions must be rugged enough to withstand the real-world demands of automotive and industrial applications, which represent about 75% of the company’s revenue.

“The semiconductor industry is really at a crossroads today,” says James Victory, who’s been a fellow of modeling and simulation at onsemi since 2012. “Architectural concepts, chip designs, and die packaging are all being revolutionized. Device capabilities are improving every day. Manufacturing capabilities are also being reimagined.”

This industry revolution includes capitalizing on the merits of non-traditional materials like silicon carbide (SiC). onsemi is leading the widespread adoption of this wide-bandgap material, which can drive the production of semiconductors that are more energy-efficient, compact, and robust than silicon-based alternatives. The result? Automotive and industrial components that are higher in performance, while both smaller in size and lower in cost.

“SiC-based semiconductors have better electrical and thermal properties than silicon alternatives, which enable them to function at higher voltages, higher frequencies, and higher temperatures. In fact, SiC-based solutions show a 4X improvement in thermal conductivity compared to traditional silicon designs,” notes Victory.

According to Victory, SiC’s superior electrical and thermal performance not only satisfies existing market requirements, but also creates new and exciting applications. “Between 650 and 1200 volts, SiC has proven to be the best solution in terms of performance efficiency across a new generation of electric vehicle, industrial solar and energy storage, uninterruptible power supply, advanced power supply, battery charging, and other high-power systems.” Victory says.

Learn about Ansys’ innovative capabilities for electrothermal applications.

Modeling a More Powerful Future With Ansys

Based on the enormous potential of SiC, onsemi is investing aggressively in research and development (R&D) efforts centered on this material.

A key focus of these efforts is evaluating device and technology performance through virtual prototyping platforms that employ Ansys software. Victory, an Ansys user since the early 1990s, was brought on board in 2012 to create an industry-leading power semiconductor design enablement capability to help place onsemi at the forefront of semiconductor product innovation. He had previously led successful design enablement initiatives at Motorola Semiconductor, Xtremespectrum, and Jazz Semiconductor.

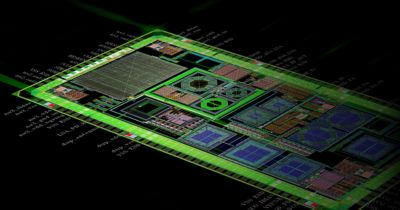

Ansys-based simulations help onsemi address design challenges created by the fast switching characteristics of SiC MOSFETs (metal-oxide-semiconductor field-effect transistors). Rapid switching effects can result in die-package interactions that influence semiconductor robustness and reliability. To mass-produce SiC power modules reliably, the product development team at onsemi must understand electrical, thermal, and mechanical interactions, as well as how they influence module performance and reliability.

“Modeling and simulation make sense in any industry, but over the course of my career, I’ve seen firsthand how they deliver incredible value for semiconductor manufacturers,” says Victory. “In fact, semiconductor companies can turn their modeling and simulation capabilities into a significant competitive advantage.” Victory believes that simulation is the best way to compress development cycles for truly groundbreaking designs, such as onsemi’s SiC chips, so fabricators can match their speed of innovation to the pace of technology and market change.

Product Innovation Begins With Process Innovation

In collaboration with Ansys, Victory and his team have developed a new method for automating and accelerating the multifidelity thermal modeling (MFIT) process used to validate onsemi’s SiC MOSFET industrial power modules.

Their innovative, proprietary approach is described in a technical paper published by IEEE Explore, titled “Automated Multidisciplinary Analysis and Lab Verification for Silicon-Carbide Based Power Modules.”

The automated, web-based MFIT process developed by onsemi and Ansys speeds the electrothermal modeling of SiC-based power module designs, while also improving its accuracy. Together, onsemi and Ansys have established a first-time, complete, and automated power module simulation platform that includes:

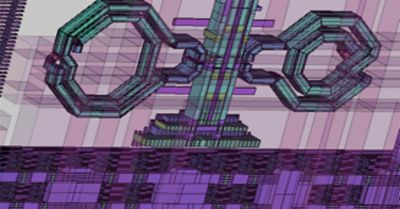

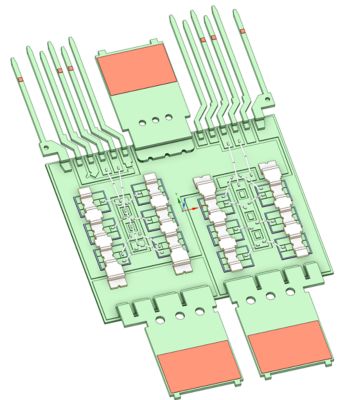

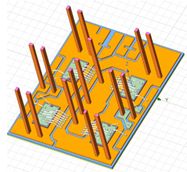

- 3D solid model generation via Ansys SpaceClaim 3D computer-aided design (CAD) modeling software

- Thermal impedance simulation using Ansys Icepak electronics cooling simulation software

- Parasitic RLC (resistor, inductor, and capacitor) parameter extraction, powered by Ansys Q3D Extractor parasitic extraction electromagnetic simulation software

As engineers iterate on the design of silicon carbide (SiC)-based power modules, onsemi’s object-based approach enables more creative freedom. A breakthrough arbitrary clip design tool accommodates complexity, enabling the modeling team to explore different clip shapes and orientations to maximize overall performance.

- Reduced-order SPICE (simulation program with integrated circuit emphasis) model generation

- The deployment of Ansys-native Python script libraries for automation

Compared to previous modeling approaches, the proprietary automated workflow at onsemi is much faster and more precise. For example, a typical finite element analysis (FEA) model generation flow includes the time-consuming, error-prone task of CAD solid model generation, followed by model import and idealization in a simulation preprocessing step. In the new onsemi-Ansys workflow, this task is replaced by fully scripted, automated 3D solid model generation with minimal user interaction.

The innovative process also eliminates unnecessary steps by automatically applying customized meshing and solution strategies for specific solid models. For instance, while modeling the active area of a chip is meaningful for thermal analysis, the modeling of all signal connectors is only needed to gauge electrical effects. The process automatically adapts to the user’s ultimate analysis goals.

The automated MFIT approach is also more flexible than traditional workflows, which depend on layering or stacking solid geometries in a prescribed order. Because onsemi’s process is object-based, each module can be composed in a bottom-up approach — starting from the root object that defines the backbone of the assembly. New layouts and complex shapes are much more easily accommodated, enabling product innovation.

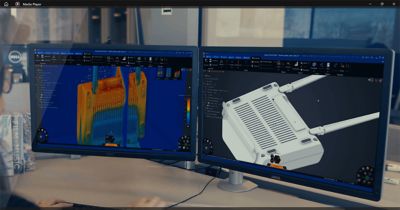

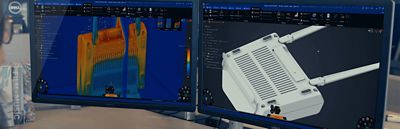

The automated MFIT process developed by onsemi and Ansys has proven very accurate in using a 3D model of a SiC MOSFET power module (left) to predict the performance of the finished product (right).

Automating Analysis Fuels Faster, More Predictable Outcomes

The results of the proprietary MFIT approach have been validated across onsemi’s SiC MOSFET industrial power modules in lab testing — which means that onsemi can now solve complex electrothermal problems both quickly and confidently via Ansys software and automated workflows.

“Physical tests and prototypes confirm that our MFIT results have a high degree of accuracy. Such ‘ first time right’ capabilities create a big advantage for onsemi in terms of speed to market with innovative and competitive products,” Victory adds.

The materials and fabrication processes associated with SiC production are very expensive, Victory emphasizes. That means the proprietary MFIT process also drives significant cost savings for onsemi by predicting product performance at a very early stage of design — before any production investments have been made.

According to Victory, today the automated MFIT process created in partnership with Ansys represents a critical component of onsemi’s end-to-end development process. The speed and rigor of the MFIT process allow onsemi to lead the industry in commercializing SiC for a wide range of customer applications.

“As with most innovations, the shift to SiC presents significant engineering and design challenges. We’re fortunate to have partnered with Ansys for many years to address these kinds of challenges — by developing design, process, and simulation flow innovations that lead directly to product innovations,” Victory concludes.

Learn more about Ansys’ semiconductor simulation capabilities.

Just for you. We have some additional resources you may enjoy.

“Modeling and simulation make sense in any industry, but over the course of my career, I’ve seen firsthand how they deliver incredible value for semiconductor manufacturers.”

— James Victory, fellow of modeling and simulation, onsemi

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.