-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

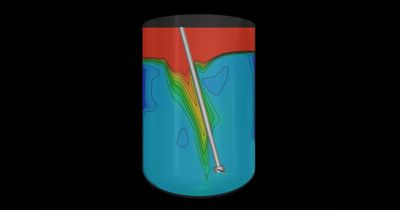

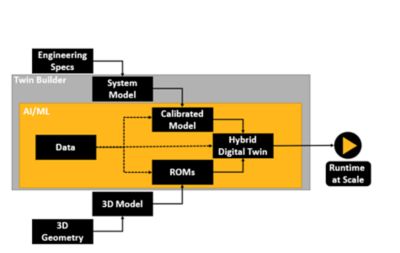

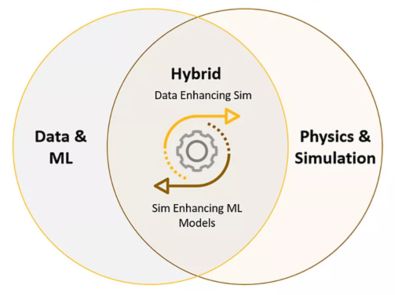

You’ve likely heard of digital twins: “virtual representations of real-world entities and processes, synchronized at a specified frequency and fidelity,” according to the Digital Twin Consortium. But what are hybrid digital twins, and how do you create them? Essentially, hybrid digital twins increase the value of digital twins by blending data and physics. Through artificial intelligence/machine learning (AI/ML) integration, you can create them using the Ansys Twin Builder simulation-based digital twin platform and Ansys TwinAI AI-powered digital twin software.

Asmaa Lapouge, a senior product marketing manager at Ansys, discusses hybrid digital twins on Ansys’ interview series “The Twin Talks.” Recently, she sat down with two Ansys experts to get an overview of hybrid digital twins, including common applications and use cases. Here are some highlights and excerpts from those interviews.

Q: Can you provide a brief overview of what hybrid digital twins are and how they differ from a traditional digital twin?

MANZOOR TIWANA, lead product manager at Ansys: The traditional digital twin, or traditional approach for these models, has been that either it’s a pure simulation — for example, in Ansys’ case we are very strong in physics and in simulation, so we have this model based on simulation and physics — and a lot of other people had it based on ML techniques like AI/ML analytics techniques. A hybrid digital twin allows you to combine the best of both worlds from simulation and physics and from AI/ML.

Q: Are there specific industries or applications where hybrid digital twins have shown significant impacts, such as optimizing operations, improving decision making, or enhancing overall performance?

Manzoor Tiwana

MT: At Ansys, we have customers across almost all industries. We have customers from aerospace, automotive, manufacturing, healthcare, energy, and oil and gas, to name a few. And the things these customers are doing, or the challenge they are facing, is how they can represent these assets or processes in a very accurate way, at the same time, making it very quick and scalable.

We have a customer who is using this hybrid digital twin in flow networks with systems consisting of palms, valves, piping — vessels that help them predict the failure in the components and then help them optimize the operation for energy efficiency. So, that could be a goal to optimize the operation and to predict a failure if there is some. We also have published a paper in IEEE with that use case that demonstrates that with a pure analytics approach, they were getting an accuracy of about 80%. And this could be different from case to case, but in that case they had an accuracy of around 80%, and they used the simulation and were getting an accuracy of around 90%. But when they combined both things, they had an accuracy of 98%. … And then we have a customer who is using this technology to predict the emissions from their engines, and they’re using this hybrid approach to limit how many simulations they have to perform. They can combine the simulation and the real data to get these results very quickly so they don’t have to do that many simulations to get to a very higher accuracy, but they can combine these two to get there very quickly.

Q: And from an Ansys perspective, can you tell us how does the company integrate hybrid digital twins into its solutions and the role of simulation in analytics in creating a holistic representation of physical assets?

MT: Twin Builder software is our product that helps build the physics-based digital twin, and then we have the TwinAI platform that performs this AI/ML integration. The TwinAI platform allows the engineers to blend the data and physics to create this advanced digital twin. So, users can also perform things like parameter calibration and fusion to create their model, which combines both the physics and the sensor data into their models.

Q: In what ways are digital twins used during product stages? What are the use cases?

VITOR LOPES, senior product sales manager at Ansys: The interesting aspect about digital twins, like any good technology, is that it’s very, very flexible and applicable to a variety of scenarios. So, if you’re talking specifically about operations or environments where you already have an asset and you’re connecting it to twins, you may be using this — one of my favorites — as a virtual sensor to take what you can measure to then measure what you cannot measure as the asset is being operated. And you can take this into different scenarios. You may use it initially for monitoring. You may use it for control. You may use it for optimization. You may then even use it to predict behavior like, “Hey, when are assets going to fail so that I can service it ahead of time and minimize costs associated with unplanned downtime?” That’s the operational world.

Vitor Lopes

There are two approaches when building a hybrid digital twin: top-down and bottom-up.

Now, imagine you are in a scenario where you have a project designed. You want to bring it to the real world, but you’re still at that commissioning stage. You may use it more as an offline twin to minimize the commissioning times and risks. Because before the product is even built, you can start understanding, “Hey, how am I going to use this product? In which conditions that may happen in the field (or) that may happen on manufacturing lines?” There are all sorts of different use cases.

And, finally, as early as product development, you may just have a digital prototype. At that stage, the asset doesn’t really exist, you’re still designing it, but you’re using the models to be able to validate designs, to optimize designs, and to understand better ways to be running in different performances. It’s the concept of virtual prototyping, virtual validation, and deciding where to place sensors.

Q: Can you share some specific examples to illustrate the impact of digital twins in the various sectors?

VL: Industries such as energy, metals, and mining — industries where they have very harsh conditions, but at the same time they need a very tight control of operations. They may be using these twins to understand specific points in the assets or the systems, the so-called virtual sensors, where operations were happening before in a more blind way. You don’t really know what’s going on, and until you actually connect the twins, you now then have the ability to start seeing, “Oh, our temperatures are too high here, pressures are too low,” things like that, and that may drive your operation to increase yields or minimize risks, costs, or performance degradation.

Hybrid digital twins combine data, physics, and artificial intelligence/machine learning (AI/ML) techniques to provide the most accurate representation of an asset.

Now, that may happen in a manufacturing setting, but for instance, we see a lot of this happening also in the aerospace and defense industry where people are actually connecting these twins to aircraft and being able to understand when services are due … in a lot more refined way. Because now with this concept of hybrid, you have the data there, but you also have the physics giving you an element of what is really going on and, if things are going to break, why are they breaking and where.

To learn more, watch the webinar “Ansys TwinAI: Combining Physics Accuracy With Data-Driven Insights.”

Just for you. We have some additional resources you may enjoy.

“A hybrid digital twin allows you to combine the best of both worlds from simulation and physics and from AI/ML.”

— Manzoor Tiwana, lead product manager, Ansys

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.