-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

ANSYS BLOG

October 9, 2019

Using Biomedical Materials within a Circular Economy

In the past, doctors routinely sterilized and reused medical tools like bandages and syringes. However, with the invention of polymers and other advanced biomedical materials, engineers focused on designing disposable medical products which helped minimize infection.

Throughout various industries, engineers are creating more sustainable designs. So, how can reusability and sustainability be incorporated into modern biomedical material and product designs?

The medical field relies on

disposable biomedical materials.

But does it have to?

One solution is to focus on building a circular economy for biomedical materials and teaching these concepts to future engineers.

How to Transfer from a Linear to a Circular Economy Using Biomedical Material

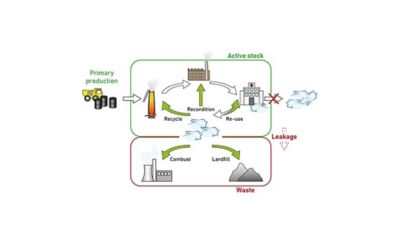

Industrial ecologists define the circular economy as a framework where raw and used material or products are looped within a system — like nature’s carbon and water cycles. The circular economy aims to eliminate waste by lengthening a product’s life or reusing waste. Conversely, the linear economy follows the take, make, use and dispose approach.

A circular economy is created when the waste that leaks out of the system

is reduced. Engineers need to design ways to recycle the waste back into the system.

The mechanisms by which products become waste can be interpreted as a loss of perceived value. This loss is caused by several factors:

- Physical obsolescence: the product breaks down beyond economic repair

- Functional obsolescence: the product is no longer needed

- Technical obsolescence: the product is outperformed by newer technology

- Economic obsolescence: the product it is no longer profitable

- Legal obsolescence: the product is made illegal due to regulation changes

- Desirability obsolescence: the product is no longer aesthetically appealing

To maintain circular economies, obsolete products must be recovered and restored to economic value by addressing all the factors that make it undesirable.

The common belief is that engineers will face a lot of complexity transferring the healthcare industry into a circular economy because the waste is often discarded for safety reasons. This can be thought of as hygienic obsolescence.

Nevertheless, the World Health Organization (WHO) estimates that 85% of the waste produced from healthcare activities are non-hazardous. Therefore, with an appropriate recovery strategy, there is a lot of transformation potential in the medical industry..

How Engineers Will Design a Circular Economy for Biomedical Materials

Engineers will find it tricky to redesign medical devices to be sustainable since any reduction in functionality, or increased risk, could endanger a patient’s life. Additionally, there will be logistical questions surrounding waste retrieval and acceptance barriers.

However, if a catheter could be sterilized to regulatory standards, while maintaining functionality, then theoretically it could be used indefinitely. The trick is to select biomedical materials that can be easily reused, sterilized and recycled.

To turn healthcare into a circular

economy, engineers need to

select biomedical materials

that can be sterilized, maintain

functionality and meet

regulatory standards.

To learn how to select sustainable biomedical materials — using CES EduPack and the Eco-Audit Tool — or how to introduce these concepts into an undergraduate curriculum, watch the webinar: Biomedical materials and the Circular Economy.

Learn how to improve the efficiency of a medical device using simulation.