-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

With the fourth industrial revolution, also known as Industry 4.0, fully underway, almost every industry — from automotive and aerospace to consumer goods and healthcare — is demonstrating a shift toward digitalization. The industrial equipment and manufacturing industries are no exception. A global industrial robotics survey revealed that industrial companies are expected to invest 25% of their capital spending on automation from 2022 to 2027. The survey also found that automation is already being implemented or piloted for many popular industrial tasks, including palletization and packaging, material handling, goods receiving, unloading, and storage.

As industrial automation becomes more common, another revolution is gaining traction: Industry 5.0. Though similar to its predecessor regarding technology integration, the fifth revolution has humans at its focus. While Industry 4.0 focused on technology and automation, Industry 5.0 focuses on the human interaction and collaboration with that technology and automation. The European Commission suggests that 5.0 will complement 4.0 but expand its focus on efficiency and productivity to include a more societal approach, with pillars for sustainability, human-centricity, and resilience.

Founded in 2018 as a spinoff of the German Aerospace Center (DLR), Agile Robots SE is dedicated to bridging the gap between artificial intelligence (AI) and robotics by developing easy-to-use, affordable, and intelligent robotic solutions that enable safe human-robot interaction. Such systems are commonly referred to as cobots, or collaborative robots. As a company that believes in the power of automation, it’s no surprise that Agile Robots incorporates simulation into its day-to-day operations to optimize workflows, accelerate timelines, and increase product quality.

Based in Munich, Agile Robots was introduced to Ansys through INNEO Solutions GmbH, an Ansys Elite Channel Partner, and integrated Ansys software through the Ansys Startup Program. Today, with its headquarters in Germany and production sites worldwide, the international high-tech company continues to incorporate Ansys’ nonlinear and multibody dynamics simulation to inform product design through structural, thermal, and impact assessments. At the same time, virtual testing and prototyping minimize the time and cost of traditional physical methods.

Agile Robots’ Yu 5 Industrial is an industrial-grade cobot with six axes that complies with the highest standards for human-robot collaboration.

Improving Workflows and Product Development

Agile Robots develops robotics systems that combine force-moment sensing and state-of-the-art vision intelligence — a unique combination resulting in user-friendly, cost-efficient robotic solutions that enable the automation of complex industrial tasks, the company says. Force-moment sensing technology enables the robotic systems to respond to forces and torques applied during tasks. Coupled with a vision system, this combination allows robots to perform delicate tasks with high precision.

The group offers four products designed to optimize the manufacturing process:

- Yu 5 Industrial: an industrial-grade cobot with six axes and a 5-kg payload. This cobot offers plug-and-play connectivity that supports seamless integration and complies with the highest standards of industrial robotics as specified in the International Organization for Standardization (ISO) 10218-1 safety requirements for industrial robots and ISO 13849 safety of machinery and safety-related parts of control systems. Safe torque sensing and safe collision detection make applications possible according to ISO/TS 15066 safety requirements for collaborative industrial robot systems.

- Diana 7: a force-controlled robot arm with seven axes supported by AI-driven software and equipped with torque sensors in every axis.

- AgileCore: powerful software that enables users to plan, execute, and evaluate entire manufacturing processes on one platform.

- Agile Hand: a multisensory robotic hand with five robotic fingers, modularly designed with consideration for the joints, size, shape, and degrees of freedom in the human hand.

Andreas Spenninger, head of industrialization and safety manager at Agile Robots

“Here at Agile Robots, we are customer-focused, which means we want to build safe and reliable products,” says Andreas Spenninger, head of industrialization and safety manager at Agile Robots. “In this modern world of fast innovation, doing trial and error is simply too time-consuming, too costly. So we developed a lean approach, which allows us to have fast iteration cycles using rapid prototyping but keep money and time in check.”

Dedicated to its customers and efficiency, Agile Robots integrates Ansys simulation to optimize design and development.

“Efficiency is part of our company culture. We can build, we can benchmark, (and) we can refine our products, which means we can push prototypes to high-quality and industrial-grade products way faster,” he says. “Ansys allows us to do virtual testing, which means we can optimize for stiffness, we can cut the weight of the system, (and) we can improve the entire durability. In the end, we have a more performant system, which means the entire system is faster. The customer, in the end, has faster cycle times. This is exactly what the customer wants.”

Engineers at Agile Robots use the Ansys Motion tool and Ansys LS-DYNA software for static and dynamic strength assessments.

Simulating for Strength, Speed, and Safety

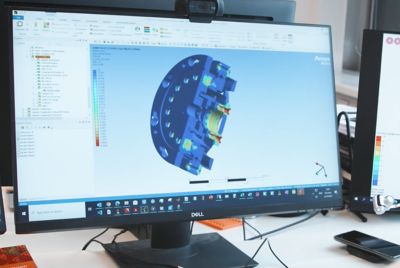

Engineers at Agile Robots use Ansys Motion multibody dynamics simulation software to perform both static and dynamic strength assessments, including harmonic response analyses.

“Ansys Motion software is used to simulate the robot’s dynamics,” Spenninger says. “This is a challenging task, and Ansys Motion greatly assists us in achieving it.”

Motion software is based on flexible multibody dynamics, which means that it supports fast, accurate analyses of rigid and flexible bodies, including system motion performance, stress safety, vibration, and fatigue.

“We chose to conduct dynamic assessments to ensure the product’s performance,” he says. “By implementing modal and harmonic response analyses, we can pinpoint the frequencies that we need to avoid.”

Agile Robots engineers integrate Ansys multibody dynamics simulation to inform product design through structural, thermal, and impact assessments.

Spenninger and his colleagues also use Ansys LS-DYNA nonlinear dynamics structural simulation software to perform thermal and impact assessments.

LS-DYNA software is rooted in explicit simulation and used for applications, including drop tests of all forms, impact and penetration, smashes and crashes, and manufacturing processes like machining, cutting, and drawing.

“Basically, Ansys is helping us to simulate whatever we need at the moment,” he says. “As a result, Ansys is helping us a lot to run any model we need to get a proper performance and to get a reliable and safe product.”

Typical industrial applications for Agile Robots’ robotic systems include machine tending, assembly, material handling, quality inspection, finishing, and dispensing.

The company says its robots and automation provide key benefits, including workforce relief by reducing repetitive tasks, increased productivity with minimized errors and downtime, and improved product quality through precision.

Agile Robots has production sites worldwide, including one in Kaufbeuren, Germany, where it produces the Yu 5 Industrial.

Developing Dynamic Change

Agile Robots says it doesn’t just want to build robots — it wants to help industrial teams establish comprehensive automation solutions.

To discover how Motion software or the LS-DYNA solver can help your team optimize product design and development, check out the on-demand webinars “Introduction to Ansys Motion” and “An Introduction to Ansys LS-DYNA.”

Just for you. We have some additional resources you may enjoy.

“Basically, Ansys is helping us to simulate whatever we need at the moment. As a result, Ansys is helping us a lot to run any model we need to get a proper performance and to get a reliable and safe product.”

— Andreas Spenninger, head of industrialization and safety manager, Agile Robots

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.