Case Study

-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

“In the midst of the once-in-a-century revolution, we believe it is essential to innovate business processes to shorten lead time in order to keep Japanese manufacturing alive. By introducing real-time CAE, I believe we have found a way to shorten the time required for development and production preparation. I would like to further contribute to the improvement of business processes by increasing the range of use of real-time CAE while verifying it with actual phenomena and conventional analysis."

— Yuki Suzuki, Engineer, Toyota

Toyota's global vision is to lead the mobility society of the future by enriching lives and societies around the world to realize "For Smiles, Beyond Expectations." To this end, everyone at Toyota is committed to building high-quality products, constantly pursuing innovation one step ahead of the times. They are maintaining an awareness of the need to be close to the global environment, with the goal of becoming carbon-neutral by 2050 through a multipathway approach. To achieve these goals, Toyota’s Powertrain Manufacturing Fundamental Engineering Division is working with product design and manufacturing through real-time computer-aided engineering (CAE) to improve the competitiveness of its products and line concepts by thoroughly increasing efficiency and shortening development time.

Challenges

The automotive industry is facing environmental challenges such as global warming and air pollution. In response, automakers have set a goal of reducing CO2 emissions by more than 50% from 2019 levels by 2035 to achieve carbon neutrality, forcing automakers to shift their focus to more sustainable powertrains. The resulting product development challenges of vehicle electrification, such as lack of resources and reduced profitability, further complicate these goals in a highly competitive market.

To solve these problems, Toyota needed to double productivity by dramatically improving efficiency and reducing development time.

Engineering Solutions

Ansys Discovery simulation software is used by Toyota to study new products and troubleshoot problems on the production line, helping the company make immediate decisions on the shop floor.

Specifically, simulation is enabling Toyota's real-time CAE strategy in three key areas.

- The accumulation of previous mechanism elucidations has improved the technical capability of CAE analysis by enabling the identification of elements that are necessary for CAE analysis, as well as those that can be omitted.

- Computer evolution, including improvements in GPU performance and automatic mesh generation, has been expedited.

- Digitization strategies related to CAD and 3D modeling have evolved.

Benefits

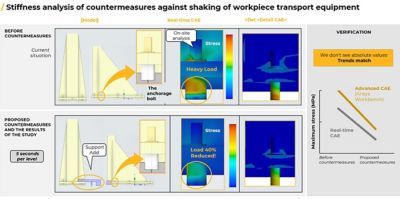

In one case, the floor surface at the anchor bolt area of a key piece of line equipment was damaged, causing a problem with significant shaking during acceleration and deceleration of the conveyor system. Actual on-site inspection revealed cracks in the floor surface, indicating the need for expeditious countermeasures.

In the past, Toyota Motor Corporation used CAE mainly for quantitative evaluations. A lot of time was spent taking individual requirements back to the field and checking the details to derive analysis results. By using real-time simulation-based CAE, members of the analysis department can go to the actual site where the problem occurs, such as the designer's site or the factory where the production site is located, and solve the problem by analyzing data at that site to enable faster decision-making.

To this end:

- Discovery software was able to identify and eliminate analysis elements and narrow down analysis points to develop immediate countermeasures at the site with a high degree of urgency.

- The initial analysis showed that the anchor bolt area was highly stressed. Based on the results, Toyota proposed a countermeasure with an additional support device that reduced the load on the anchor bolt by 40%.

- As verification, comparison with the detailed analysis also confirmed that the trend of the analysis results before and after the countermeasure implementation was consistent with the results of this analysis.

- Overall, real-time field response analysis with Discovery software reduced the study time by 93% compared to other detailed CAE methods. The validation results obtained from the analysis show trend values that are critical to the rapid study of effective solutions.

On-site rigidity analysis and discussion enables early visibility of countermeasures.

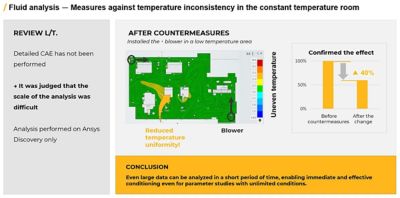

Another use case involved the application of real-time CAE to maintain a uniform temperature in a constant temperature chamber designed to sustain high temperatures and high- or low-humidity conditions. A preliminary analysis of the situation revealed the air could not circulate well due to indoor equipment. A difference in temperature was also observed depending on chamber location. In consideration of large-scale spatial data, it was necessary to implement real-time CAE with help from Discovery software.

To this end,

- A parametric study in Discovery software significantly reduced temperature irregularities in constant chambers by placing blowers in optimized positions.

- Discovery software was able to instantly generate effective conditions for unconditional parametric studies because of its ability to quickly analyze even large datasets, such as the thermostatic chamber.

Proposed optimal conditions from parameter studies, taking advantage of short analysis time

Toyota was able to simplify the model by identifying which elements were needed and which could be omitted during the analysis, despite the size and scale of the thermostatic conditions.

In the future, with help from Ansys tools and solvers, Toyota also plans to build a real-time CAE environment that can be used by designers and field personnel.

See What Ansys Can Do For You

See What Ansys Can Do For You

Contact us today

Thank you for reaching out!

We’re here to answer your questions and look forward to speaking with you. A member of our Ansys sales team will contact you shortly.