Case Study

-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

“Utilizing Ansys Discovery was a turning point for our team's engineering efforts. We harnessed its precision to meticulously enhance our F1 car's components and aerodynamics. As a result, we achieved significant performance improvements, notably refining our lap times. This tool redefined our design possibilities and played a crucial role in propelling Team Aurora's success in the fiercely competitive F1 in Schools competition.”

— Jay Zhao, Director of Engineering, Team Aurora

The F1 in Schools competition is a worldwide science, technology, engineering, and mathematics (STEM) program that has engaged 20 million students to date. The event examines a multifaceted team, scrutinizing several project elements: branding, marketing, racing, portfolios, verbal presentations, and, most importantly, engineering. Students are required to use computer-aided engineering (CAE) software to create, analyze, and optimize their race cars. Countless hours are spent using industry-level analysis software to sharpen each team’s competitive edge.

Challenges

Beginning from a primitive and basic car assembly, Team Aurora, through relentless research and analysis, upgraded and gradually improved critical components of the vehicle. To understand how, why, where, and what the team can improve, extensive simulation is required — hence its vast utilization of the Ansys engineering product Discovery. Ansys Discovery permits Team Aurora to conduct detailed and accurate aerodynamic analysis so Aurora can improve their vehicle and aim for first place in racing.

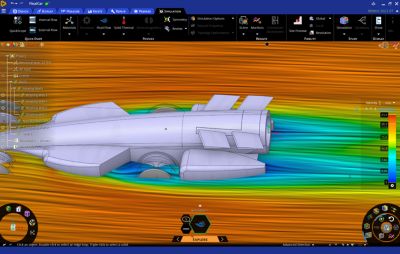

Examples of aerodynamic details that arise as a result of the efficient and accurate Ansys computational fluid dynamics (CFD) software include the turning vanes integrated into the car's suspension geometry. This component was crucial in ensuring consistent flow conditions around important aerodynamic components such as the rear wing and in washing side pods. Furthermore, we were able to perfect the geometry of the diffuser and floor of the car by implementing and comparing different designs and concepts, thanks to the powerful processing power of Discovery.

Team Aurora holding the Golden Turbo, the Australian National Champions trophy.

Engineering Solution

Discovery provided engineers with accurate and consistent data that was crosschecked with physical wind tunnel data, allowing the team to reliably develop and iterate the geometry of small components and aerodynamic surfaces. Specifically, the following features were used:

- Wind tunnel setup with the Prepare tab.

- Easy manipulation of the physics that the car is exposed to.

- Monitor points to analyze the contribution that each component gives to vehicle performance.

Team Aurora used the Explore mode within the Discovery interface. This mode allows for the quick visualization of flow patterns interacting with different car components without the lengthy process of having to customize the mesh with specific settings. This lowered the simulation and iteration time significantly for rapid prototyping.

Team Aurora's National Finals-winning car in front of the Sydney Harbour bridge.

Benefits

- Car performance increased by reiterating components. Estimated lap time gained is 0.1-0.2 seconds (15% performance gain).

- Gained knowledge and proficiency. Discovery acted as a great steppingstone into more advanced programs such as Ansys Fluent.

- 30% of time saved with Discovery. Ansys Discovery is able to reduce the time spent on CFD simulations and aerodynamic development as a result of its streamlined workflows and user-friendly interface. One particular aspect of the Discovery software is its ability to iterate efficiently with different configurations of aerodynamic elements at different airspeeds, which is essential to the analysis of a F1 in Schools car as the velocity of the car changes with time.

CFD simulation of Team Aurora's National Finals car.

Let’s Get Started

If you're facing engineering challenges, our team is here to assist. With a wealth of experience and a commitment to innovation, we invite you to reach out to us. Let's collaborate to turn your engineering obstacles into opportunities for growth and success. Contact us today to start the conversation.