Case Study

-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

“Virtual prototyping in Ansys Maxwell makes it easy for us to change the design parameters of our components to meet the varying requirements of regional markets, minimize the number of physical prototypes, and ultimately reduce project timing by an entire development cycle. The simulation software also enabled us to reduce the weight of the copper wire used in the electromagnetic clutch design by 20% and reduce customer costs in the process”

— Stephan Marcet

Electric Motor and Electromagnetic Clutch Development Engineer, Sanden Manufacturing Europe

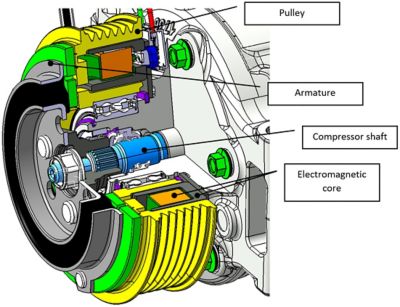

Sanden Manufacturing Europe, a division of the Sanden Group in Japan and part of Sanden Europe, is developing mechanical and electrical compressors for internal combustion engine, hybrid, and electric vehicle (EV) applications. The belt compressor design includes an electromagnetic (EM) clutch based on a magnetic circuit, delivering excellent wear resistance and controlled slippage for smoother operation. Despite its obvious benefits, the generic clutch design was optimized exclusively for the Japanese automotive market. Sanden hoped to validate clutch performance and modify some dimensions or tolerances to localize the design for the European market and meet customer requirements for noise, power consumption, reliability, and cost.

Challenges

To compete effectively in an already crowded marketplace required Sanden Europe to take a reliable baseline Japanese design and optimize it for each of its European customers — a task that involved the complex distillation of EM clutch performance based on a vehicle’s constraints. Each unique set of customer objectives required in-depth performance analysis subject to dimensional and tolerance modifications of the original clutch. Also important was advanced study that led to significant weight and cost reductions overall for the customer. Sanden also required a simulation solution in support of its current request for quotation (RFQ) process.

Engineering Solutions

Sanden’s computer-aided engineering (CAE) team uses Ansys simulation tools — including Ansys Maxwell, Ansys Motor-CAD and Ansys Mechanical — for two specific components: the EM clutch for mechanical compressors and the electric motor for electrical compressors. The pulley of the clutch is the interface between its compressor and the car internal combustion engine, so it was standardized to match within individual customer constraints.

For each new project, Ansys software helps Sanden (in the case of an electromagnetic clutch):

- Develop a new pulley design by calculation of the magnetic performance.

- Check the impact of some modifications requested by clutch suppliers or deviation requests in case of nonconformity.

- Enable some design optimization for better performance, as well as significant weight, noise, and cost reduction.

Benefits

- Responded quickly to customer RFQs that called for specific requirements and changes in existing motor designs by relying on Motor-CAD. The software also delivered quick analysis to confirm the impact of specific modifications of the motor parameters on the overall design.

- Achieved a 20% reduction in copper wire weight and introduced this modification in mass production for several million compressors by per-forming design experiment (DoE) study calculations in Ansys Maxwell.

- Identified, evaluated, and satisfied customer requests for higher performance component designs by using Maxwell to connect specifications and emerging customer requirements.

- Verified the noise level of the compressor to optimize vehicle acoustics by calculating the magnetic force of the motor in Maxwell and transferring that data to Ansys Mechanical (in the case of electromagnetic compressors).

- Avoided the purchase of expensive hardware to run analyses by using laptops, marking it an extremely flexible, portable computing solution that can burst to the cloud if needed.

Electromagnetic clutch of a mechanical compressor

Let’s Get Started

If you're facing engineering challenges, our team is here to assist. With a wealth of experience and a commitment to innovation, we invite you to reach out to us. Let's collaborate to turn your engineering obstacles into opportunities for growth and success. Contact us today to start the conversation.