Case Study

-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

“Ansys Zemax OpticStudio software turned a complex redesign into a precise and efficient process, ensuring accuracy without unnecessary overhauls.”

- Niké Ackerman, Design Engineer, NewSpace Systems

The Aquila D01 sun sensor from NewSpace Systems (NSS) is a proven and reliable system with extensive in-orbit heritage. It features a detector housed beneath a metal mask with precision-cut slits. As sunlight passes through these slits, it creates a unique one-dimensional brightness profile on the detector. This pattern is then analyzed to determine the sun's position. In 2022, the linear array used in the Aquila D01 was discontinued, prompting an effort to redesign the sun sensor to meet updated component availability.

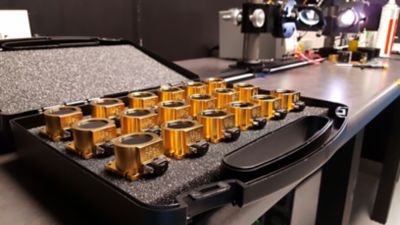

Figure 1. NSS Aquila Sun Sensor at the calibration test setup

Challenges

The redesign led to the development of the Gen 1.5 Aquila sun sensor. NSS needed to integrate a new detector that would maintain the form fit and function of the original design, improve manufacturability, and avoid disruptions to existing embedded processing and calibration algorithms. A replacement detector was identified. However, due to differences in the photosensitive area of the detectors, the embedded algorithm and calibration were compromised, leading to reduced accuracy.

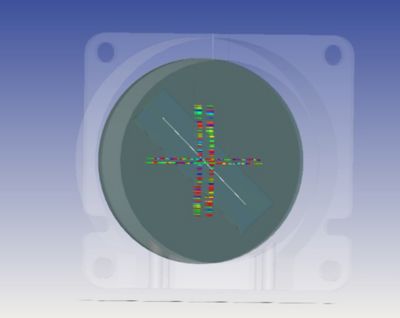

Figure 2. Simulation results showing the projected image pattern onto the detector

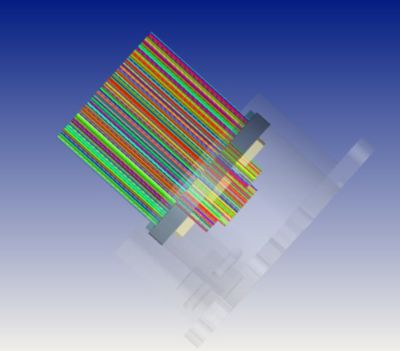

Figure 3. Simulation results from the ray tracing performed with Ansys Zemax OpticStudio software

Engineering Solutions

To minimize mechanical changes, NSS used Ansys Zemax OpticStudio optical system design and analysis software to simulate potential design modifications, identifying the simplest adjustments needed to achieve desired accuracy. Through this approach, they tested various iterations, including adjustments to the optical filter material, minor modifications in the detector's placement, and optimized component alignment. This simulation-based approach enabled NSS to quickly evaluate multiple configurations, ensuring the new sensor could meet precision requirements while enhancing manufacturability.

Benefits

By conducting these simulations early in the redesign, NSS streamlined the development process and mitigated costly adjustments down the line. Previously, only 13% of Gen 1 Aquila sensors achieved the desired accuracy of below 0.1°. With the Gen 1.5 redesign, all sensors now meet this stringent accuracy threshold, underscoring the value of early-stage simulation.

Let’s Get Started

If you're facing engineering challenges, our team is here to assist. With a wealth of experience and a commitment to innovation, we invite you to reach out to us. Let's collaborate to turn your engineering obstacles into opportunities for growth and success. Contact us today to start the conversation.