Case Study

-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

“When developing a student formula car, time and funds are limited. Ansys simulation software enabled us to use time and resources efficiently, achieving our development goals in a short time.”

— Heishiro Fukuoka, Aero Development Leader, FEM

At its core, Formula Student is a design competition that provides students around the globe with an opportunity to design, build, and test a Formula-style racing car. Nagoya University’s Formula team FEM participates in Formula SAE Japan (FSAEJ), a branch of this competition founded in 2003.

Not only does FEM want to win this competition — a goal they have accomplished previously — but they are also aiming to design the first electric vehicle (EV) to achieve overall victory.

Challenges

As a student team, FEM has limited time and funds to contribute to the FSAEJ competition, making efficiency imperative. At the same time, the team can not sacrifice accuracy because they need to perform detailed structural and aerodynamic analyses of composite materials to gain results that they can reproduce in a real vehicle. As a result, FEM turned to Ansys simulation software to perform multibody dynamics (MBD) analyses.

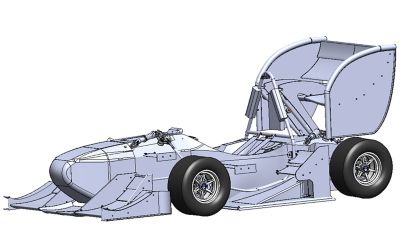

Nagoya University’s Formula team FEM and the vehicle they developed

Engineering Solutions

FEM applied simulation analysis to their work to better visualize and optimize their designs. They relied on Ansys software for its:

- Visualization capabilities. Ansys simulations offered the ability to view detailed stress distributions, pressure distributions, and flow at any location.

- Mesh settings. With Ansys software, FEM could make detailed mesh settings and link these to quantitative indicators (such as y+) for confirmation.

An Ansys simulation of FEM’s Formula-style racing car

Benefits

With Ansys simulation software, FEM was able to overcome the major obstacles they faced when designing their Formula vehicle.

- By using simulation, the student team was able to progress more efficiently. For example, the detailed visualizations generated by Ansys software were ideal for immediate reflection when designing their Formula Student machine, in which time was of the essence.

- With Ansys simulation, FEM was able perform an aerodynamics analysis of a full-machine model, which would have been challenging to do without simulation.

Let’s Get Started

If you're facing engineering challenges, our team is here to assist. With a wealth of experience and a commitment to innovation, we invite you to reach out to us. Let's collaborate to turn your engineering obstacles into opportunities for growth and success. Contact us today to start the conversation.