Case Study

-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

“We are developing environmental technologies that promote the circular economy, based on the perspective of ‘creating and continuing to care for the foundation for life.’ Ansys' multiphysics simulations, which cover a wide range of physical domains, play a very important role in this development. In particular, Ansys' integrated simulation technology accelerates the creation of innovative solutions and enables an efficient development process. We are using this advanced tool to accelerate the construction of sustainable social infrastructures.”

— Takashi Nakayama, R&D General Manager, JFE Engineering Corporation

The idea of a resource-recycling society has recently attracted attention, and waste incineration facilities are expected to play an increasingly important role in maintaining the urban environment. The waste incineration facilities built and operated by JFE Engineering Corporation not only perform their original role of burning trash to make it harmless and reduce its volume, but also use heat recovery to turn steam turbines and generate electricity. They also play an important role as decentralized renewable energy supply facilities.

Computational fluid dynamics (CFD) analysis was used to understand the combustion conditions inside the waste incinerator. As a result, counterflow combustion technology that enables more stable and efficient combustion was developed.

After that, JFE Engineering developed a discrete element method (DEM)-CFD coupled simulation to understand the behavior of waste being unsteadily introduced and transported into the incinerator, with the aim of creating an incinerator with lower combustion fluctuations and less environmental impact.

Waste combustion diagram illustrating the solid-gas interaction

Challenges

- Complying with regulations related to reducing environmental impact. Because the facility is responsible for making waste harmless, it is required to meet strict environmental regulations regarding waste volume and waste quality.

- Increasing power generation and improving energy efficiency. Expectations for it to be used as an energy supply facility are increasing, and there is a need to improve power generation capacity and provide a stable energy supply.

- Reducing construction and running costs to enhance competitiveness of orders in private sector outsourcing.

Two major technical challenges were also present:

- Reduce the amount of environmentally regulated substances produced in incinerators.

- Suppress power generation and combustion fluctuations.

The nature and size of trash is not uniform and varies greatly depending on the season and region. For example, the percentage of moisture that affects combustibility varies between 30% and 50%, and the calorific value accordingly varies from 7-10 MJ per kilogram. Another major feature of this fuel is that it has a high chlorine and nitrogen content and contains impurities such as metals. These factors make stable combustion difficult.

Additionally, the supply of waste may not be constant. Generally, it is difficult to continuously supply garbage due to the unevenness of the garbage. In other words, it is difficult to maintain a steady state, which causes combustion to fluctuate.

Finally, the combustion mechanism is complex. Since fluctuations in power generation are caused by fluctuations in combustion, it was necessary to understand the combustion behavior inside the furnace and optimize it by adjusting the oxygen concentration.

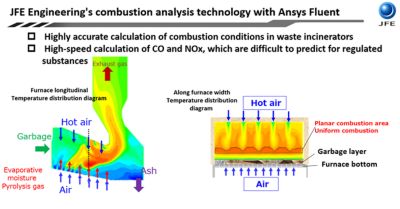

JFE Engineering's combustion analysis technology with Ansys Fluent software

Engineering Solutions With Ansys Fluent Software

- By combining the research and development results of waste surface temperature and volatile content obtained through laboratory experiments with Fluent software's numerical analysis technology, JFE Engineering improved the accuracy of calculations of the combustion state in waste incinerators.

- Fluent software’s excellent user interface, its powerful parallel computing technology, and its ability to use a wide variety of physical models such as combustion was critical. Another important point was the ability to quickly calculate CO/NOx, which is a regulated substance and difficult to predict.

- By quantitatively and visually understanding various combustion conditions, JFE Engineering developed counterflow combustion technology that allows for even more stable and efficient combustion by blowing high-temperature air from the ceiling.

- Simulation of a new combustion type was conducted in advance and its effectiveness was verified. Simulations were used to examine the arrangement and flow velocity of the blown air in advance to find more effective design conditions.

Benefits From Fluent Software

By utilizing this simulation, JFE Engineering improved the efficiency of development and shortened the development period by approximately 30%. As a result, this counterflow combustion technology reduced NOx emission concentration by approximately 20% and significantly improved power generation capacity. Furthermore, combustion stability was also improved.

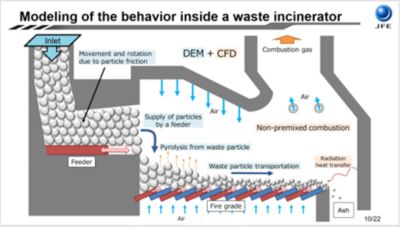

Modeling the behavior inside a waste incinerator

Engineering Solutions With Ansys Rocky Software

To create an incinerator with even lower combustion fluctuations and environmental impact, JFE Engineering utilized DEM-CFD analysis and simulation analysis for a 100 ton/day furnace. it was necessary to optimize the shape and operating conditions of the grate and dust supply equipment to stabilize the supply of garbage to the grate. It was also important to suppress combustion fluctuations due to unsteady garbage supply and changes in garbage calorific value.

To analyze these, it was necessary for JFE Engineering to understand the behavior of garbage being unsteadily introduced and transported into the furnace. They first conducted powder experiments and obtained powder behavior. They then attempted to determine the parameters by reproducing the experimental results using DEM analysis.

Copyright © 2024 JFE Engineering Corporation All Rights Reserved.

Waste incinerator model with DEM-CFD coupling simulation result

Benefits From Rocky Software

- The Material Wizard in Rocky software enables users to quickly estimate parameters that satisfy conditions in the DEM through a series of simple inputs.

- One of the results of a coupled DEM-CFD analysis shows that the dust that contained moisture in the sheet section is fed into the furnace, and as it is transported to the right, the moisture content decreases. JFE Engineering confirmed that water evaporates due to the heat inside the furnace, and it was found that gas-solid reactions can be analyzed by coupling DEM and CFD.

- JFE Engineering is also using Ansys software to develop a DEM-CFD coupled simulation that uses DEM to analyze the transport behavior and gas phase reactions of waste and all interactions with them.

Let’s Get Started

If you're facing engineering challenges, our team is here to assist. With a wealth of experience and a commitment to innovation, we invite you to reach out to us. Let's collaborate to turn your engineering obstacles into opportunities for growth and success. Contact us today to start the conversation.