Case Study

-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

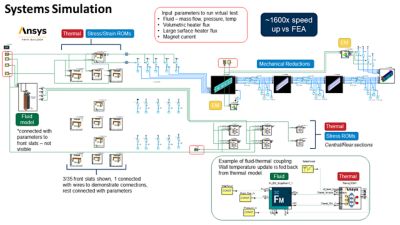

“We want to develop a system simulation, which is what we've been building in Ansys Twin Builder. And the reason we've chosen this software is its flexible fidelity. You can analyze simpler components like equations, up to coupling with full physics codes. It's modular, enabling us to split a model down into its different components, and then, if those need updating, we can quickly swap them in and out. And it's fast so that we're able to do as many probabilistic simulations and design studies as we want as we work toward a real-time digital twin.”

— Michelle Tindall

Engineering Analyst, Simulation Research, U.K. Atomic Energy Authority

UK Atomic Energy Authority (UKAEA) Uses Ansys Twin Builder to Model Fusion for Clean Energy Production

The United Kingdom (UK) invests 650 million pounds (792 million dollars) to help cement the UK as a world leader in the fusion sector, creating thousands of fusion training places. Alongside this, UK Atomic Energy Authority (UKAEA) is building a unique test rig called CHIMERA (Combined Heating and Magnetic Research Apparatus). The test rig is specifically designed to test meter scale prototype components in an environment representative of a fusion power plant.

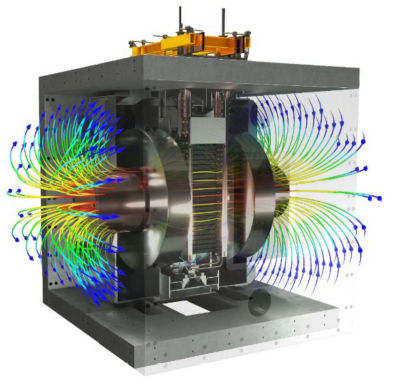

Figure 1. The U.K. Atomic Energy Authority (UKAEA) is building a test rig of a reactor called CHIMERA, and using simulations to optimize its output.

Challenges

Within the tokamak (tordial chamber with magnetic coils) of a fusion reactor, hydrogen fuel is subject to extreme pressure and temperatures in excess of 100 million degrees Celsius to create extremely hot, electrically charged plasma. Future operational success requires an understanding of how all the components that sit next to the plasma within the tokamak will survive high loads imposed by electromagnetic fields, high heat flux, and temperature variations due to coolant loop flow. In light of prohibitive timescales and costs, fully replicating the operational environment is only possible with prototype fusion reactors. Further, complications posed by in-operation diagnostics, in-service inspections, and potential in-vessel failures establish the need for predictive maintenance based on in situ monitoring that is independent of more traditional instrumentation and data collection.

Engineering Solution

UKAEA, with the help of Ansys Twin Builder, is working toward the creation of a fusion component digital twin that will be used for the virtual testing and monitoring of all of the components.

A system simulation approach is well-suited to this purpose, as it is:

- Fast

- Multidomain (i.e., designed for coupling mechanical, thermal and fluid domains together)

- Modular (i.e., multiple models can be connected into a single simulation for easy updates to individual parts)

- Able to add flexible fidelity that enables high-fidelity simulation coupling

Also essential is the development of coupled simulation models capable of system design optimization and virtual component qualification under conditions that are not readily tested. A component digital twin combining data from physical instrumentation with simulation will be used to deliver virtual, real-time diagnostics in support of future predictive maintenance of the reactor.

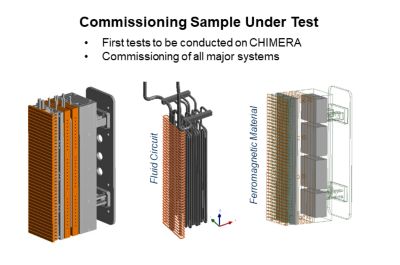

Figure 2(a). CHIMERA Commissioning sample under test.

Figure 2(b). Multiphysics systems simulation of CHIMERA commissioning sample under test performed by UKAEA with Ansys Twin Builder.

Comparison of tested and simulated post damage

Benefits

- Creating a multidomain co-simulation/connection of 1D elements, developing reduced-order models, and utilizing standard languages and exchange formats (FMI) resulted in fast-running multiphysics that will support probabilistic simulation design studies and real-time predictive maintenance via digital twin.

- Performing a static electromagnetic analysis in Ansys Maxwell, for example, to calculate the net forces experienced by the ferromagnetic components due to a static magnetic field generated by super-conducting magnets yielded results within a maximum absolute error of 700 N and a percentage error of 3%.

- Using CHIMERA-driven simulations enables researchers to optimize their design of experiments (DOEs) to build confidence and capability in simulation models through calibration to test.

- Initial systems simulation results of CHIMERA commissioning sample under test (CSUT) indicate that the simulation speed, accuracy, and complexity of the methodology used will achieve the fast-running validated component models needed for a fusion component digital twin.

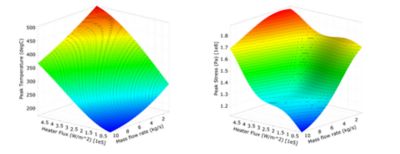

Thanks to the system simulation UKAEA can simulate many components such as this example where simulation shows the temperature variation across front slats due to mass flow. Parameter sweeps were completed to understand the test envelope.

Figure 3a, 3b. Example of temperature variation across front of commissioning sample under test due to mass flow and thermal/Stress peak values obtained in Ansys OptiSlang performed by UKAEA.

See What Ansys Can Do For You

See What Ansys Can Do For You

Contact us today

Thank you for reaching out!

We’re here to answer your questions and look forward to speaking with you. A member of our Ansys sales team will contact you shortly.