ACCELERATE YOUR DESIGN PROCESS

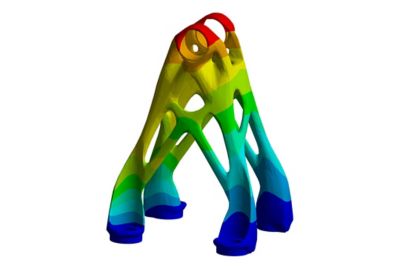

Real-time Topology Optimization Paired with 3D Printing Drives Innovation

Explore multiple manufacturable designs in minutes through a fast and interactive experience, where you can define objectives easily and apply controls to ensure that manufacturing requirements are met, minimum material thicknesses are set and exclusion areas are defined.