Quick Specs

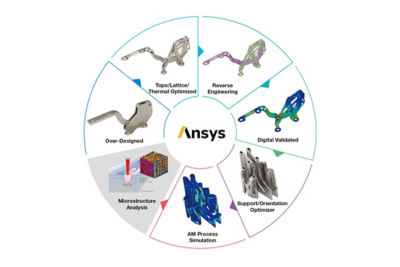

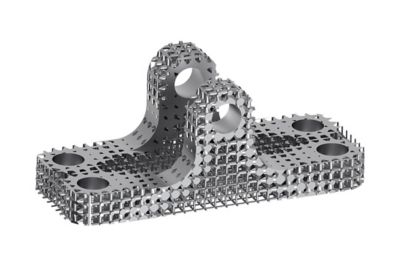

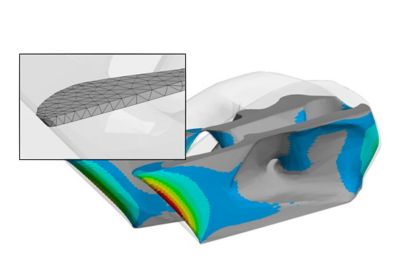

Delivering critical insights required by designers, engineers and analysts, Ansys Additive Suite is a comprehensive workflow solution. Spanning the entire workflow, from design for Additive Manufacturing (DfAM) through validation, print design and more, this solution helps avoid build failure and deliver accurately designed parts.