Don't miss these Additive Manufacturing Webinars

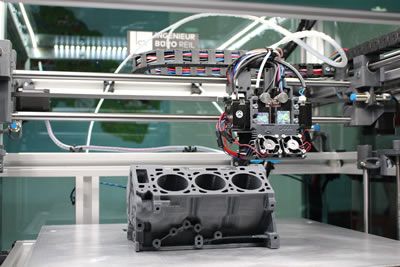

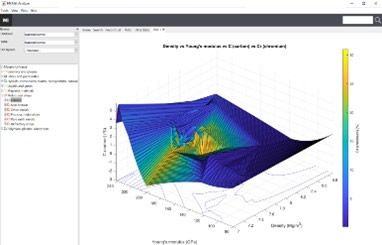

As additive manufacturing (AM) technology evolves, better understanding of the data generated during AM projects becomes vital to realizing its potential. This applies both to empirical data, derived from production and testing, to data generated by simulation packages that help users understand material, process and machine parameters.

The resultant traceability through data capture can typically result in cost savings upward of 25%, with double-digit repeatability improvements achievable by using data analytics. Finally, by allowing the free flow of data through integrated design and simulation tools, time to market for AM projects can be decreased by up to 20%. Join our webinar series to learn more about this.