-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

-

Contact Us -

Careers -

Students and Academic -

For United States and Canada

+1 844.462.6797

PRESS RELEASE

DATE: 12/05/2019

Telma Shortens Path to Market for Frictionless Braking Systems with Ansys

Ansys multiphysics simulation solutions reduce number of physical prototypes by 10x

PITTSBURGH, December 5, 2019 – Telma, the world leader in frictionless braking systems, significantly shortened time to market and optimized product development costs using Ansys (NASDAQ: ANSS) for three new series of retarders — braking systems that use electromagnetic induction. With Ansys, Telma decreased the number of prototypes required for validation from 10 to one over the course of a decade — enabling faster development of retarders that reduce fine-particle emissions associated with braking systems by up to 90% while significantly reducing maintenance costs.

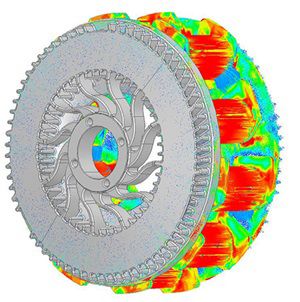

Magnetic flux density on stator and power loss density on rotor

Retarders are used in heavy vehicles, mining applications, wind turbines and elevators to dissipate most of the large amounts of energy produced during deceleration. This requires testing and validating the retarders under extreme conditions to ensure the function and safety of the application. With Ansys, Telma engineers replaced their time-consuming and expensive physical prototyping and testing process with simulation, enabling engineers to better manage the electromagnetical, fluid and structural mechanic phenomena at work. Using Ansys' high-fidelity multiphysics simulation solutions to model, simulate and validate these virtual prototypes, Telma significantly reduced costs and accelerated time to market.

"With the simulation solutions from Ansys, we have complete control over all three physics and can validate our models in one iteration," said Nicolas Quennet, director of research and development at Telma. "Our engineers can easily duplicate models to simulate all or part of the products, which also boosts innovation. Furthermore, as a leader in engineering simulation software, Ansys represents a guarantee of excellence and quality for both existing and prospective customers."

"Telma's products are vital – not only because they help with essential vehicle safety issues — but also because of their positive environmental impact," said Chris Wolfe, lead product manager of systems coupling and data analytics at Ansys. "Telma's team faces true multiphysics engineering challenges and our multiphysics solutions proved to be a perfect fit for clearing those hurdles. It's rewarding to see our software and consultation having such a positive impact on product development and optimizing resources."

About ANSYS, Inc.

If you've ever seen a rocket launch, flown on an airplane, driven a car, used a computer, touched a mobile device, crossed a bridge or put on wearable technology, chances are you've used a product where Ansys software played a critical role in its creation. Ansys is the global leader in engineering simulation. Through our strategy of Pervasive Engineering Simulation, we help the world's most innovative companies deliver radically better products to their customers. By offering the best and broadest portfolio of engineering simulation software, we help them solve the most complex design challenges and create products limited only by imagination. Founded in 1970, Ansys is headquartered south of Pittsburgh, Pennsylvania, U.S.A. Visit www.ansys.com for more information.

Ansys and any and all ANSYS, Inc. brand, product, service and feature names, logos and slogans are registered trademarks or trademarks of ANSYS, Inc. or its subsidiaries in the United States or other countries. All other brand, product, service and feature names or trademarks are the property of their respective owners.

ANSS-C

See What Ansys Can Do For You

See What Ansys Can Do For You

Contact us today

Thank you for reaching out!

We’re here to answer your questions and look forward to speaking with you. A member of our Ansys sales team will contact you shortly.